9,10-dihydro-9-oxa-10-phosphenanthrene-10-oxide (DOPO) group phosphorus-nitrogen flame retardant and preparation method and application thereof

A technology of nitrogen-phosphorus flame retardants and flame retardants, applied in chemical instruments and methods, organic chemistry, compounds of Group 5/15 elements of the periodic table, etc., can solve the problem of affecting the mechanical properties of cured resins and reduce the vitrification of cured resins Transformation temperature, can not meet the processing temperature and other problems, to achieve the effect of environmental protection, material comprehensive performance improvement, easy to control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

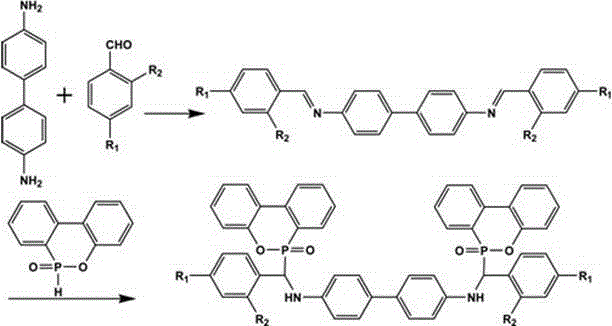

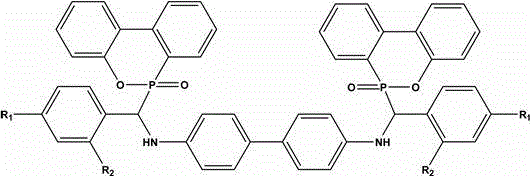

[0026] Nitrogen phosphorus flame retardant ( 1 ) The synthetic steps are as follows:

[0027] In a three-necked flask equipped with a stirrer and a reflux condenser, add 18.4g 4,4'-diaminobiphenyl, 21.2g benzaldehyde, and 400g ethanol, stir, control the reaction temperature at 50°C, and cool down after 4 hours of reaction , and then the reaction mixture was filtered, washed, and dried in an oven at 80° C. for 6 h to obtain a yellow imine intermediate with a yield of 93%.

[0028] Add 18.0g of imine, 21.6g of DOPO, and 400g of ethanol obtained above into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 50°C, react for 10 hours, cool down, and then filter the product , washed, and dried in an oven at 80°C for 8 hours to obtain a pale yellow solid nitrogen-phosphorus flame retardant ( 1 ), yield 94%.

[0029] The resulting product nitrogen phosphorus flame retardant ( 1 ) carried out infrared spectroscopy, NMR, ...

Embodiment 2

[0037] Nitrogen phosphorus flame retardant ( 2 ) The synthetic steps are as follows:

[0038] Add 18.4g of 4,4'-diaminobiphenyl, 24.4g of p-hydroxybenzaldehyde, and 400g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir, and control the reaction temperature at 50°C. After 4 hours of reaction After cooling, the reaction mixture was filtered, washed, and dried in an oven at 80°C for 6 hours to obtain a brown imine intermediate with a yield of 93%.

[0039]Add 19.6g of imine, 21.6g of DOPO, and 400g of ethanol obtained above into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 50°C, react for 10 hours, cool down, and then filter the product , washed, and dried in an oven at 80°C for 8 hours to obtain a beige solid nitrogen-phosphorus flame retardant ( 2 ), yield 91%.

[0040] The resulting product nitrogen phosphorus flame retardant ( 2 ) carried out infrared spectroscopy...

Embodiment 3

[0048] Nitrogen phosphorus flame retardant ( 3 ) The synthetic steps are as follows:

[0049] Add 18.4g of 4,4'-diaminobiphenyl, 24.4g of salicylaldehyde, and 400g of ethanol into a three-necked flask equipped with a stirrer and a reflux condenser, stir, control the reaction temperature at 50°C, and cool down after 4 hours of reaction. Then the reaction mixture was filtered, washed, and dried in an oven at 80°C for 6 h to obtain a yellow imine intermediate with a yield of 91%.

[0050] Add 19.6g of imine, 21.6g of DOPO, and 400g of ethanol obtained above into a three-necked flask equipped with a stirrer and a reflux condenser, stir and control the reaction temperature at 50°C, react for 10 h and then cool, then filter the product. Washed and dried in an oven at 80°C for 8 h, the obtained light yellow solid nitrogen-phosphorus flame retardant ( 3 ), yield 93%.

[0051] Gained nitrogen phosphorus flame retardant ( 3 ) carried out infrared spectroscopy, NMR, mass spectrometry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com