CA-(PLA-ran-PLC-b-PEC) periodic copolymer and preparation method and application thereof

A technology of block copolymers and copolymers, which is applied in medical formulations, medical preparations of non-active ingredients, medical science, etc., can solve problems such as poor hydrophilicity, slow degradation rate, and affecting the scope of application, and achieve good biophase capacitive, simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

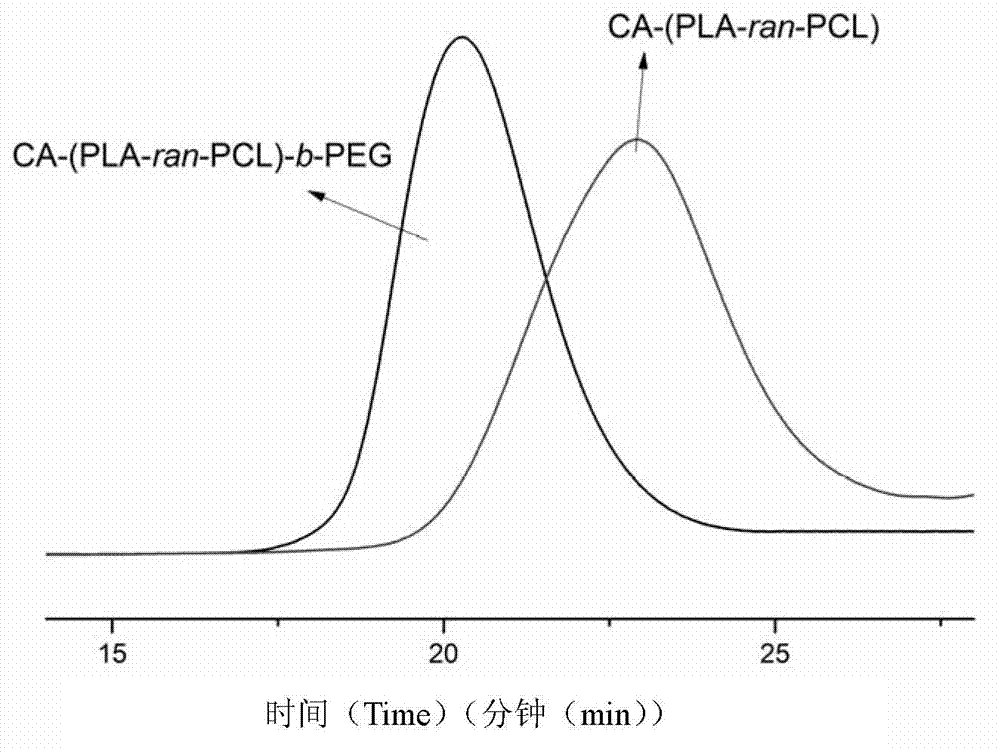

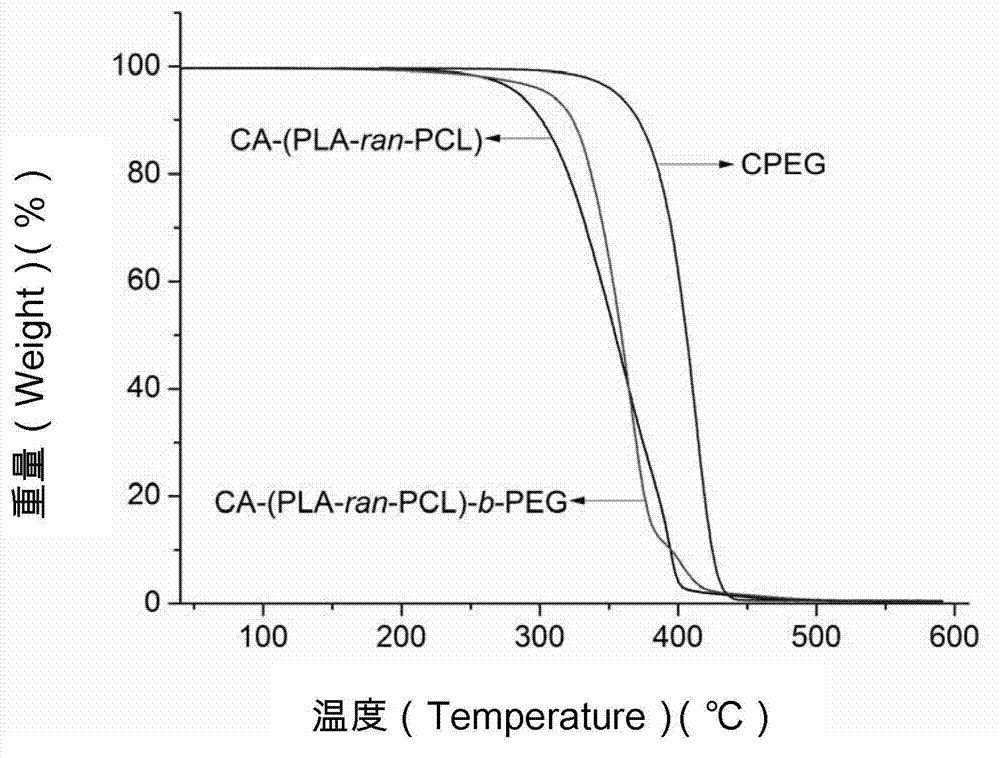

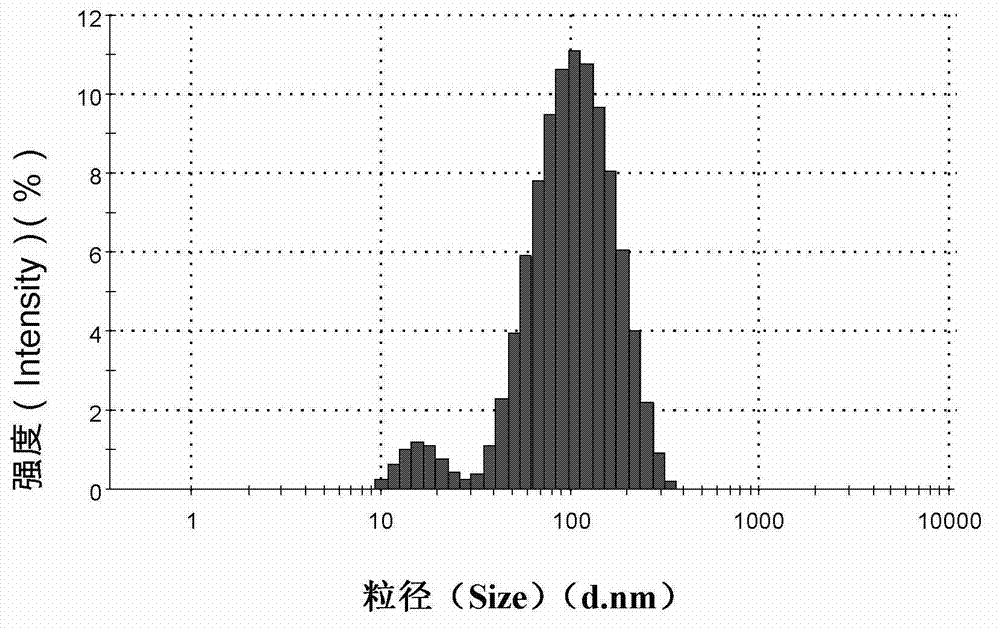

[0065] Embodiment 1, preparation CA-(PLA-ran-PCL)-b-PEG star copolymer

[0066] The preparation method of CA-(PLA-ran-PCL)-b-PEG star copolymer, comprises the steps:

[0067] (1) Take 95% lactide monomer, 4% caprolactone monomer and 1% cholic acid (CA) as raw materials according to the molar percentage, put them into the polymerization tube, add 0.5% of the monomer molar amount %Tetramethyldibutylguanidine acetate, evacuated, filled with nitrogen, repeated three times, when the vacuum degree was higher than 70pa, the polymerization tube was sealed, heated at 145°C, and reacted for 12 hours, and the number average molecular weight obtained was 36000 (m= 135, n=18) copolymer CA-(PLA-ran-PCL).

[0068] (2) get 30% PEG (Mn=4000) by mole percentage, 40% carboxylation reagent succinic anhydride (SA), 30% catalyst 4-dimethylaminopyridine (DMAP) and triethylamine, wherein DMAP The molar ratio of triethylamine and triethylamine is 1:1. Add the solvent dioxane equivalent to 10 times ...

Embodiment 2

[0071] Embodiment 2, preparation CA-(PLA-ran-PCL)-b-PEG star copolymer

[0072] The preparation method of CA-(PLA-ran-PCL)-b-PEG star copolymer, comprises the steps:

[0073] (1) Weigh 17.28g (0.12mol, i.e. 66% of the total molar amount of reactants) of lactide monomer, 6.84g (0.06mol, also i.e. 33% of the total molar amount of reactants) of caprolactone Monomer and 0.61g (0.0015mol, also 1% of reactant molar total amount) cholic acid (CA) are raw materials, put into polymerization tube, add the stannous octanoate of 0.5% of monomer molar weight as catalyzer, Vacuumize, fill with nitrogen, repeat three times, seal the polymerization tube with an alcohol torch, heat and react at 145°C for 12 hours, and obtain a copolymer CA-(PLA- ran-PCL).

[0074] (2) Weighing PEG (Mn=2000) with a quality of 4g (2mmol), 0.26g (2.6mmol) carboxylation reagent succinic anhydride, 0.348g (2.8mmol) catalyst 4-dimethylaminopyridine (DMAP) and 0.256 g (2.5 mmol) catalyst triethylamine. 50ml (51g)...

Embodiment 3

[0080] Embodiment 3, preparation CA-(PLA-ran-PCL)-b-PEG star copolymer

[0081] The preparation method of CA-(PLA-ran-PCL)-b-PEG star copolymer, comprises the steps:

[0082] (1) Take 65% lactide monomer, 15% caprolactone monomer and 20% cholic acid (CA) as raw materials according to the molar percentage, put them into a polymerization tube, and add 0.5% molar amount of raw materials Catalyst iron acetylacetonate, vacuumize, fill with nitrogen, repeat 3 times, seal the tube under vacuum, melt and react at 155°C for 12 hours, and obtain a copolymer with a number average molecular weight of 6200 (m=12, n=10) Material CA-(PLA-ran-PCL).

[0083] (2) get 40% PEG (Mn=1000) by mole percentage, 45% carboxylation reagent maleic anhydride, 15% catalyst pyridine and diethylenetriamine, wherein the molar ratio of pyridine and diethylenetriamine is 1 : 1. Add solvent toluene equivalent to 8 times the mass of the raw material, and the coupling reaction temperature is 25°C. After 40 hours...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com