Preparation method and application of nano composite flame retardant containing DOPO and delamination graphene

A nano-composite and exfoliated graphite technology, applied in the field of flame retardant design, can solve the problems of easy agglomeration and difficulty in dispersion of graphene, and achieve the effect of improving flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

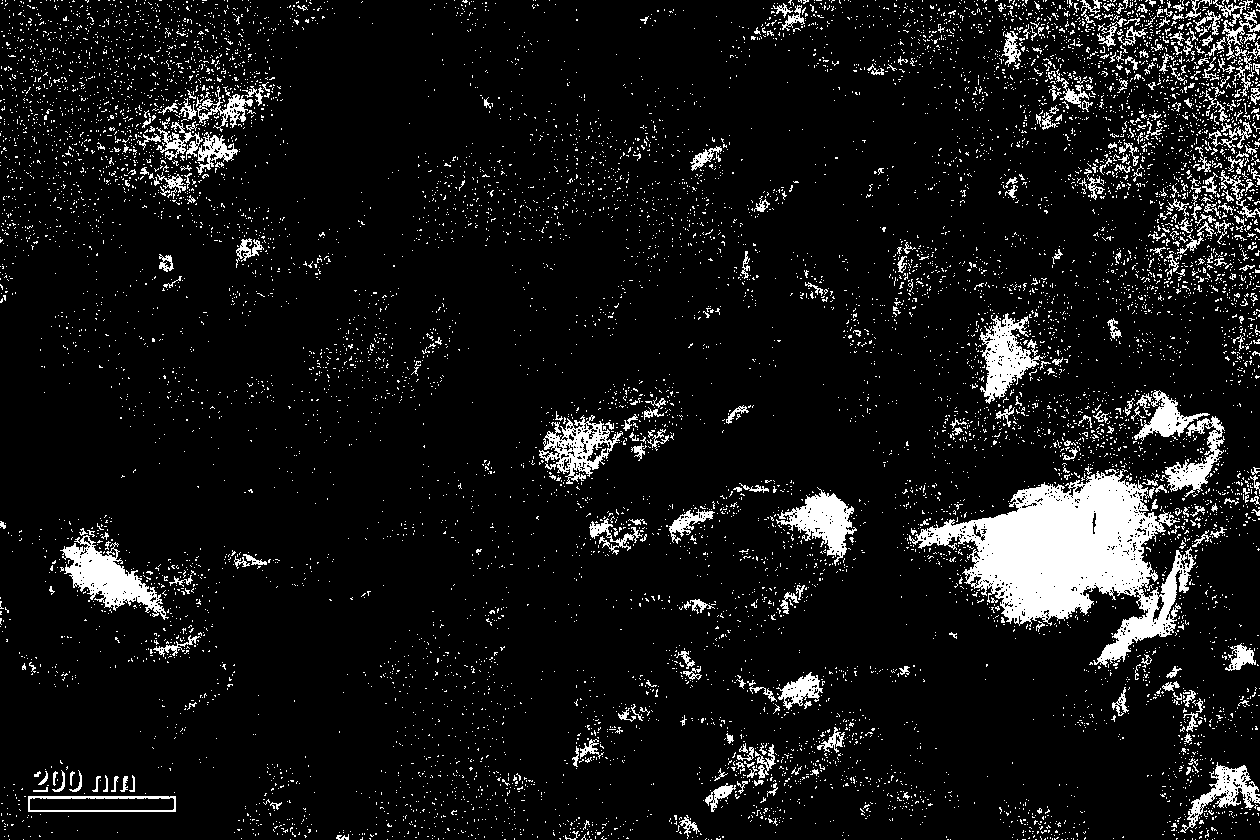

Image

Examples

Embodiment 1

[0030] In a 500 ml three-neck flask equipped with a mechanical stirrer, disperse 1 g of graphene in 200 ml of tetrahydrofuran, stir it ultrasonically to make it evenly dispersed, add 1 g of 3-isocyanatopropyl trimethoxysilane and 0.1 g of dibutyltin dilaurate Ester, heated to 60°C, reacted for 12 hours under continuous stirring, then added 9g of DOPO-VTS-1, 1ml of ammonia water and 9ml of distilled water into the above reaction system, and reacted for 3 hours. The solvent tetrahydrofuran was distilled off under reduced pressure to obtain a black solid powder, which is the nanocomposite flame retardant containing DOPO and exfoliated graphene in this example. The yield was 90%.

[0031] Take 1.25g of the above-prepared black solid powder (i.e. nanocomposite flame retardant containing DOPO and delaminated graphene) and 20g of epoxy resin and stir evenly at 60°C, then add 4.35g of 4,4-diaminodiphenylmethane As a curing agent, pour the flame-retardant epoxy resin liquid into a ...

Embodiment 2

[0033] In a 500 ml three-necked flask equipped with a mechanical stirrer, disperse 1 g of graphene in 200 ml of tetrahydrofuran, stir ultrasonically to make it uniformly dispersed, add 0.3 g of 3-isocyanatopropyltrimethoxysilane and 0.1 g of triethylamine , heated up to 60°C, and reacted for 5 hours under continuous stirring, then added 7g DOPO-VTS-2, 1ml hydrochloric acid, and 9ml distilled water into the above reaction system, and reacted for 3 hours. The solvent tetrahydrofuran was distilled off under reduced pressure to obtain a black solid powder, which is the nanocomposite flame retardant containing DOPO and exfoliated graphene in this example. The yield was 87%.

[0034] Take 1.50g of the black solid powder prepared above (that is, the nanocomposite flame retardant containing DOPO and exfoliated graphene) and 20g of epoxy resin and stir evenly at 60°C, then add 4.35g of 4,4-diaminodiphenylmethane As a curing agent, pour the flame-retardant epoxy resin liquid into a...

Embodiment 3

[0036] In a 500 ml three-neck flask equipped with a mechanical stirrer, disperse 1 g of graphene in 200 ml of chloroform, stir ultrasonically to make it evenly dispersed, add 0.6 g of 3-isocyanatopropyltrimethoxysilane and 0.1 g of dibutyltin di Lauric acid ester, heated up to 70°C, reacted for 12 hours under continuous stirring, then added 8g of the mixture of DOPO-KH-1 and DOPO-KH-2, 1ml of acetic acid, and 8ml of distilled water into the above reaction system, reaction 5 Hour. The solvent chloroform was distilled off under reduced pressure to obtain a black solid powder, which is the nanocomposite flame retardant containing DOPO and exfoliated graphene in this example. The yield was 91%.

[0037] Take 1.75g of the above-prepared black solid powder (i.e. nanocomposite flame retardant containing DOPO and delaminated graphene) and 20g of epoxy resin and stir evenly at 60°C, then add 4.35g of 4,4-diaminodiphenylmethane As a curing agent, pour flame-retardant epoxy resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com