Oligomer, polyimide film/fiber containing oligomer and preparation method of polyimide film/fiber containing oligomer

A polyimide film, polyimide precursor technology, applied in the preparation of carboxylic acid amides, the preparation of organic compounds, chemical instruments and methods, etc., can solve the mechanical strength, heat resistance and other properties of polymer materials. The problems such as the decrease of elongation at break and the decrease of thermal stretchability can achieve the effects of excellent thermal stretchability, tensile strength and elongation at break, and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] At room temperature, add biphenyldiamine dissolved in N-methylpyrrolidone dropwise into benzoyl chloride while stirring. After the dropwise addition, continue to stir for 6 hours. When filtering, wash with deionized water for 5 times, and then dry the obtained powdery solid in vacuum at 100° C. for 6 hours. The molar ratio of diphenyldiamine and benzoyl chloride used is 3:1.

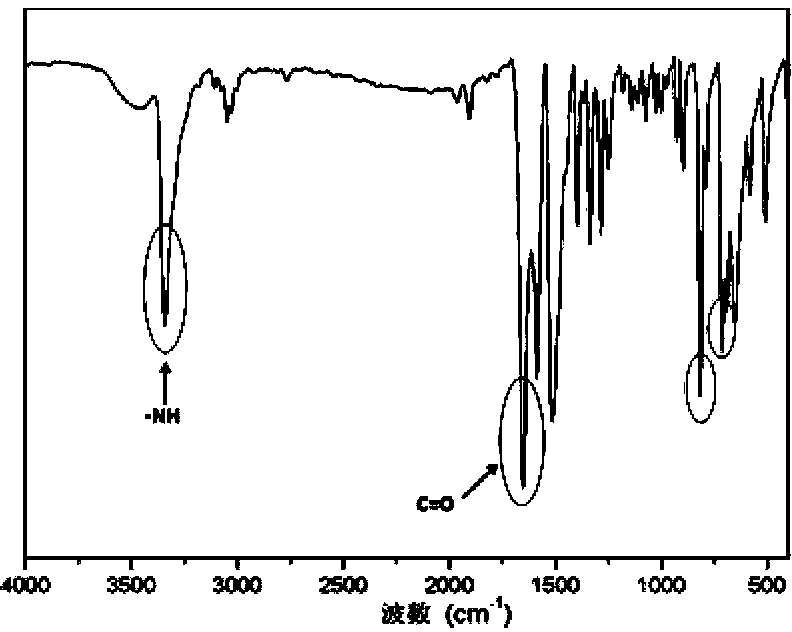

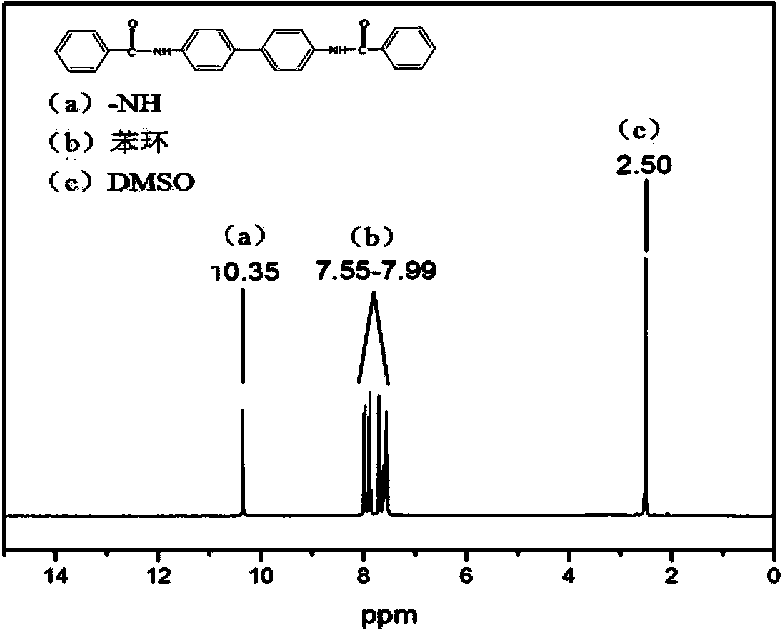

[0049] The fusing point of gained oligomer Q1 is 367 ℃, and its infrared spectrum (FTIR), hydrogen nuclear magnetic resonance spectrum ( 1 H-NMR) see respectively figure 1 , 2 .

Embodiment 2

[0051] At room temperature, add 4,4'-diaminodiphenyl ether diamine dissolved in N-methylpyrrolidone dropwise to benzoyl chloride while stirring. After the dropwise addition, continue stirring for 5 hours; add to the reaction solution Precipitate in ethanol with a volume ratio of 1:6 for 1 hour, then filter with suction, and dry the obtained powdery solid in vacuum at 100°C for 5.5 hours. The molar ratio of 4,4'-diaminodiphenyl ether diamine to benzoyl chloride is 1:2.5.

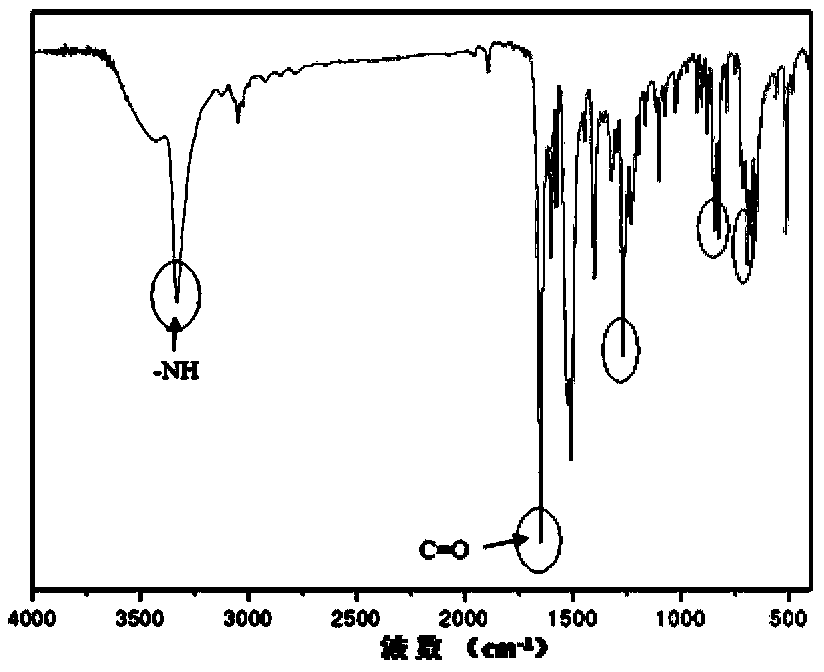

[0052] Gained oligomer Q2 fusing point is 268 ℃, its infrared spectrum (FTIR), hydrogen nuclear magnetic resonance spectrum ( 1 H-NMR), the spectra are shown in image 3 , 4 .

Embodiment 3

[0054] At room temperature, add 3,3'-dihydroxy-4,4'-biphenylenediamine dissolved in N-methylpyrrolidone dropwise into benzoyl chloride while stirring, and continue stirring for 5.5 hours after the dropwise addition; Add deionized water with a volume ratio of 1:4 to the reaction solution for precipitation for 2 hours, then filter with suction, and dry the obtained powdery solid in vacuum at 100°C for 5 hours. The molar ratio of 3,3'-dihydroxy-4,4'-biphenyldiamine to benzoyl chloride used was 1:3.5.

[0055] The fusing point of gained oligomer Q3 is 317 ℃, and its infrared spectrum (FTIR), hydrogen nuclear magnetic resonance spectrum ( 1 H-NMR), the spectra are shown in Figure 5 , 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com