Method and apparatus of controlling supplement of nutrient salts to culture microalgae based on optical density feedback

A feedback control and optical density technology, applied in the direction of microorganism-based methods, enzymology/microbiology devices, photobioreactors, etc., can solve problems such as low yield and affecting production control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] The microalgal species used was Spirulina platensis (Spirulina platensis, 439, freshwater algae species bank of the Typical Culture Collection Committee of the Chinese Academy of Sciences), and the above-mentioned algae species were used for fed-batch culture based on OD feedback control to supplement nutrients.

[0064] The composition of culture medium and nutrient salt feeding solution is the same as that of Comparative Example 1.

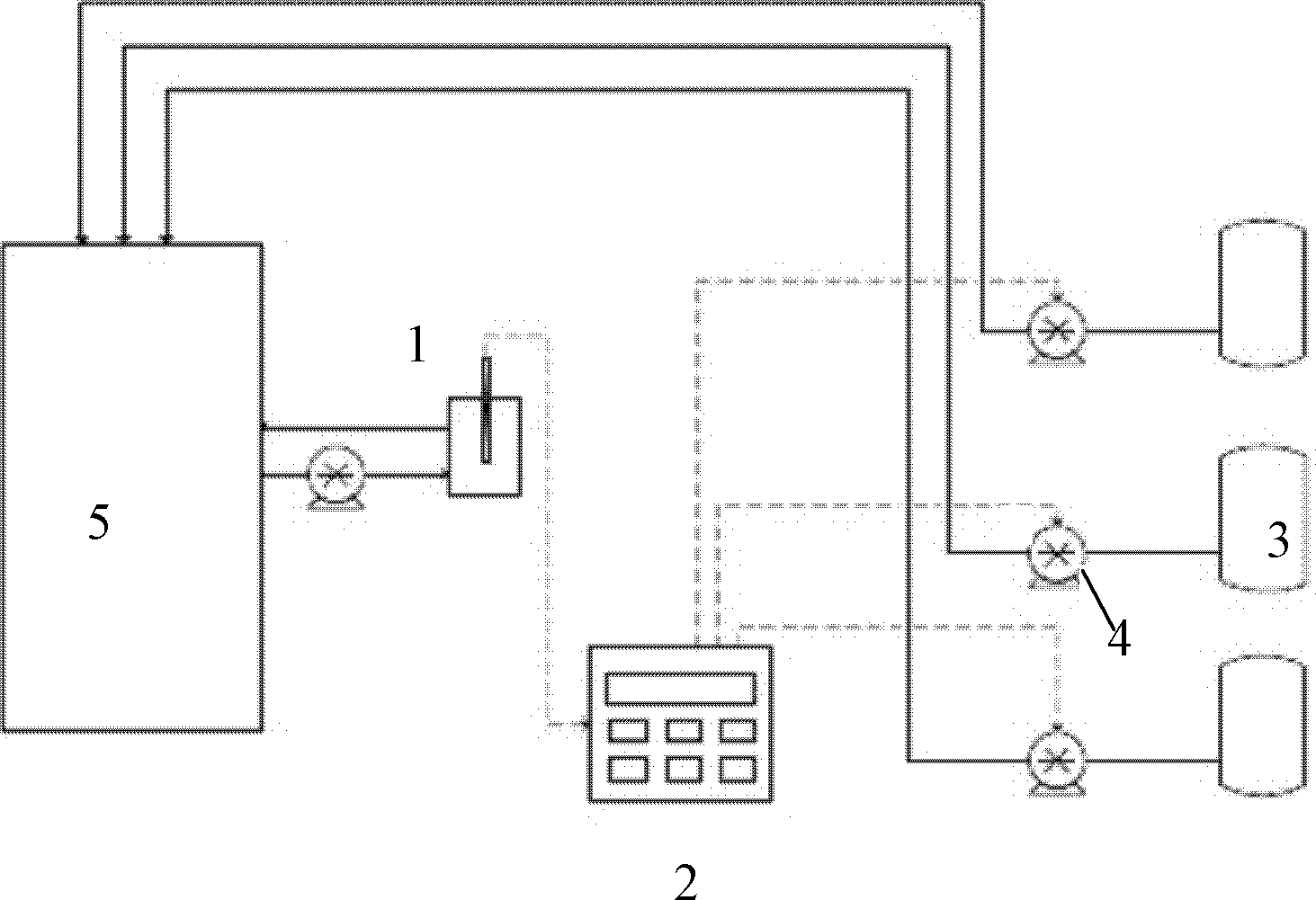

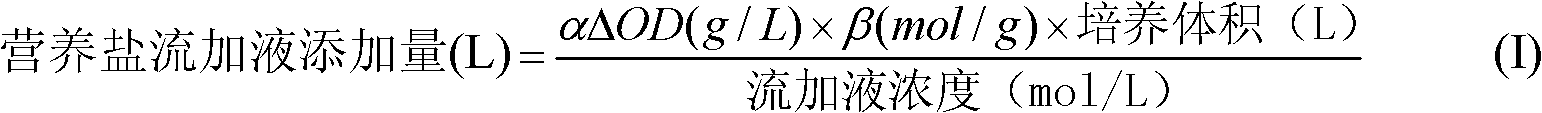

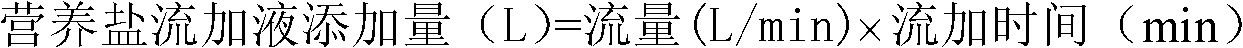

[0065] Microalgae cultivation device is 1000m 2 The open raceway pool uses an impeller stirring device to drive the flow and mixing of the culture solution, and the thickness of the culture solution layer is 15cm. See Nutrient Control Devices figure 1 , wherein the optical density sensor is a commercially available online OD sensor (GX-2, Nanning Anshengda Technology Co., Ltd.), the detection wavelength is 650nm, and the controller is an automatic controller. When the increment of the OD value exceeds the increment of the set OD value, ...

Embodiment 2

[0068] The algae species, culture medium, microalgae incubator and nutrient salt control device are the same as in Example 1. The above-mentioned medium is not sterilized, and is directly prepared in the raceway pool before adding algae species. The initial algae cell concentration is 0.15g / L, the temperature is natural (22-37°C), the light is natural light, and the light intensity is 575-1200μmol / m 2 .s, the flow rate of the culture medium is 15m / min. Nutrient salt feeding liquid is the mixed aqueous solution of ammonium sulfate, dipotassium hydrogen phosphate, wherein the concentration of ammonium sulfate is 2.5mol / L, and the concentration of dipotassium hydrogen phosphate is 0.21mol / L (the concentration ratio of ammonium sulfate and dipotassium hydrogen phosphate Determined by the ratio of the consumption of the two in the constant-speed pulse fed-batch culture of Comparative Example 1).

[0069] During the cultivation process, the OD value of the initial culture medium wa...

Embodiment 3

[0075] The microalgae used is Spirulina platensis (Spirulina platensis, 439, freshwater algae species bank of Type Culture Collection Committee, Chinese Academy of Sciences). The above-mentioned algae species were used for fed-batch culture based on OD feedback control of nutrient supplementation.

[0076] The composition of the medium is: sodium bicarbonate 8.4g / L, sodium nitrate 0.5g / L, phosphoric acid 0.1g / L, sodium chloride 1.0g / L, potassium chloride 1.0g / L, magnesium sulfate 0.1g / L, Ferrous sulfate heptahydrate 0.01g / L, disodium EDTA 0.08g / L, calcium chloride 0.04g / L. Nutrient salt feeding liquid is the mixed aqueous solution of sodium nitrate, phosphoric acid and magnesium sulfate, and wherein the concentration of sodium nitrate is 1.5mol / L, and the concentration of phosphoric acid is 0.065mol / L, and the concentration of magnesium sulfate is 0.005mol / L (sodium nitrate, The concentration ratio of phosphoric acid and magnesium sulfate is determined by the ratio of the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com