Method for manufacturing multi-layer metal mobile microstructure on metal base

A multi-layer metal and metal substrate technology, applied in the electrolytic process, electroforming and other directions, can solve the problems of difficulty in making movable microstructures, easy separation, fragile substrates, etc., to achieve strong impact resistance, high microstructure strength, Good verticality of side walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

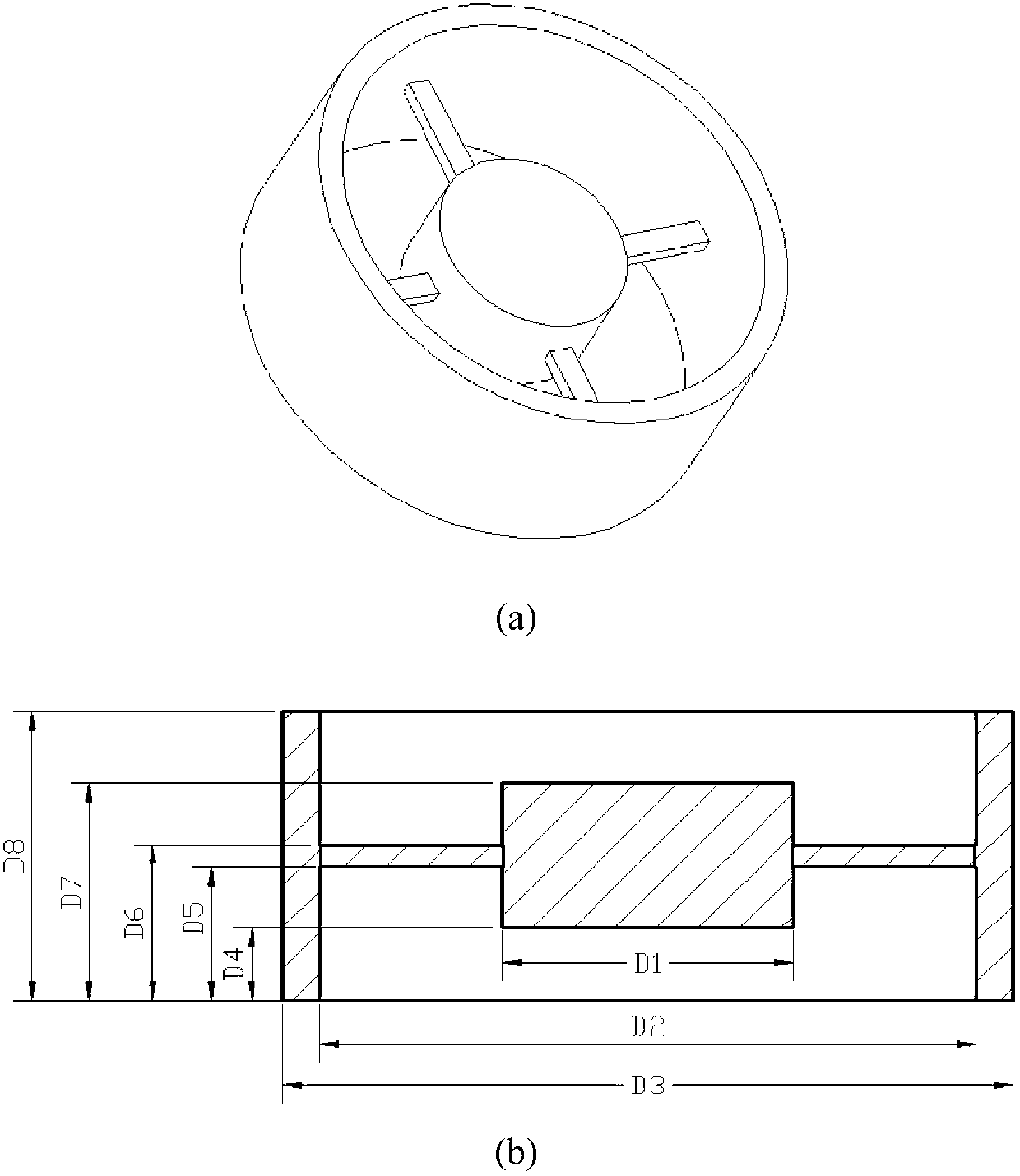

[0033] The specific implementation manners of the present invention will be described in detail below in combination with the above technical solutions and accompanying drawings.

[0034] For example: to make a multi-layer metal movable microstructure on a high-purity nickel plate with a nickel content of 99.99% after fine grinding and polishing. The size of the nickel plate is 63×63×3㎜. The specific steps for making this structure are as follows:

[0035] (1) Substrate pretreatment: The substrate pretreatment is divided into two parts: mechanical processing pretreatment and surface cleaning; the substrate material is high-purity nickel plate; the surface roughness Ra value of the nickel plate substrate after machining is 0.03-0.04 μm; the surface cleaning adopts After wiping with acetone cotton ball, ultrasonically clean in acetone and ethanol for 15 minutes respectively;

[0036] (2) Make the alignment mark on the back: perform SU-8 photoresist photolithography on the back o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com