Hydrotalcite having sodium content limited to ultra-low volume, method for preparing same, and synthetic resin composition containing same

A technology for synthetic resins and manufacturing methods, applied in the directions of hydrotalcite, nanotechnology for materials and surface science, nanotechnology, etc., can solve problems such as low performance, low productivity, increased manufacturing cost, etc., and achieve thermal degradation resistance Excellent, low manufacturing cost, effect of suppressing scrap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

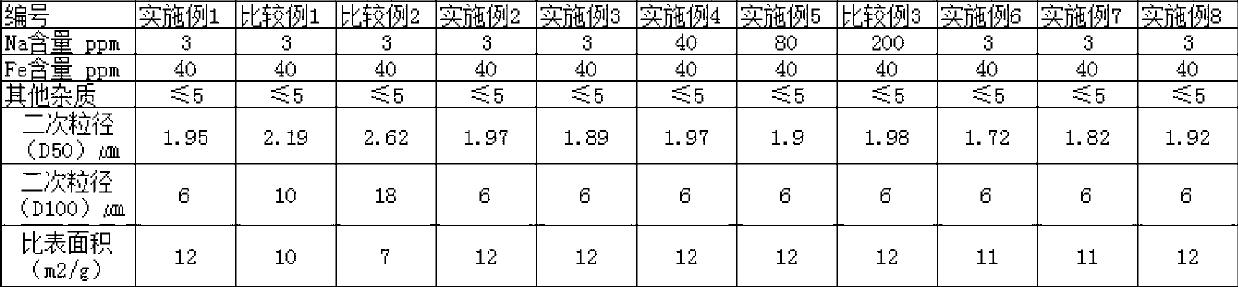

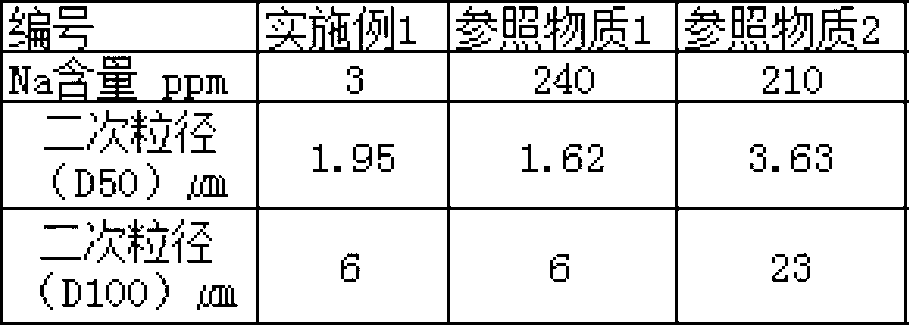

[0045] Hereinafter, the present invention will be described in more detail by way of examples and comparative examples. Each raw material used in the comparative example, that is, in addition, magnesium sulfate heptahydrate, sodium hydroxide, sodium carbonate also use high purity, that is, use the hydrotalcite of the embodiment of the present invention that the purity is 99.9% or more compared.

Embodiment 1)

[0047] 2L of distilled water was poured into the 3L raw material tank 1, and 0.903mol of magnesium oxide and 0.42mol of aluminum hydroxide were slowly dispersed. Use a wet mill (wet mill, Netzsch bead mill, zirconia ball 0.1mm, SUS304) to pulverize the mixed aqueous solution A at 3000 rpm for 60 minutes, so that the secondary particle size of the pulverized mixed aqueous solution becomes D50 0.75 μm / D100 1μm. Pour 2L of pulverized mixed aqueous solution B into a 3L reaction tank, and after sealing it, quantitatively measure 0.21mol of CO in a high-pressure vessel 2 Finally, inject into the reaction tank containing the reactant in stirring until the pressure becomes 0kg / cm 2 . CO injected 2 The subsequent mixed aqueous solution C was subjected to hydrothermal synthesis at 170° C. for 6 hours. After that, the cooled slurry was transferred to a 3L surface treatment tank, and the temperature was raised to 80°C and maintained. After stirring, 3 g of stearic acid was added, and ...

Embodiment 2)

[0059] 2L of distilled water was poured into 3L of raw material tank 1, and 0.861mol of magnesium oxide and 0.42mol of aluminum hydroxide were slowly dispersed. The mixed aqueous solution A was pulverized at 3000 rpm for 60 minutes with a wet mill so that the secondary particle diameter of the pulverized mixed aqueous solution was D50 0.75 μm / D1001 μm. Pour 2L of pulverized mixed aqueous solution B into the reaction tank, and after sealing, quantitatively measure 0.21mol of CO in the high-pressure vessel 2 After that, inject 2.1 mol of CO into the reaction tank containing the stirred reactant 2 until the pressure becomes 0kg / cm 2 . CO injected 2 The subsequent mixed aqueous solution C was subjected to hydrothermal synthesis at 170° C. for 6 hours. Afterwards, the cooled slurry was transferred to a 3L surface treatment tank, and the temperature was raised to 80°C and maintained. After stirring, 20 g of stearic acid was added, and the surface treatment was completed by stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Secondary particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com