Solid nano porous membrane with temperature sensitive response characteristics and preparation method thereof

A nano-porous, responsive technology, applied to electrical components, circuits, battery pack components, etc., can solve problems such as narrow adjustment range, dangerous occurrence, and diaphragm fusing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

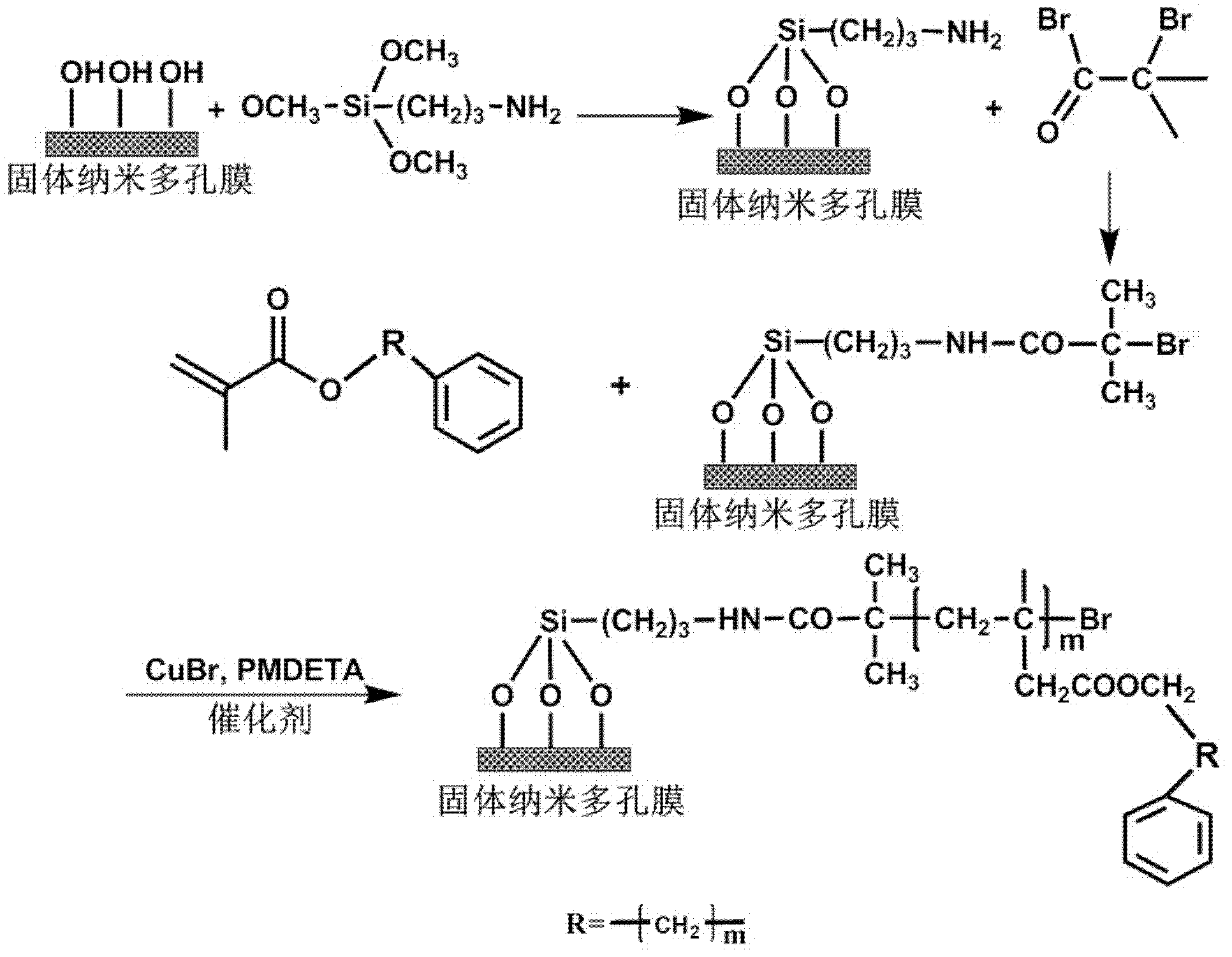

[0039] See figure 1 and figure 2 , to prepare anodized aluminum oxide nanoporous membranes with temperature-sensitive response properties.

[0040] 1). Surface treatment of anodized aluminum nanoporous membrane

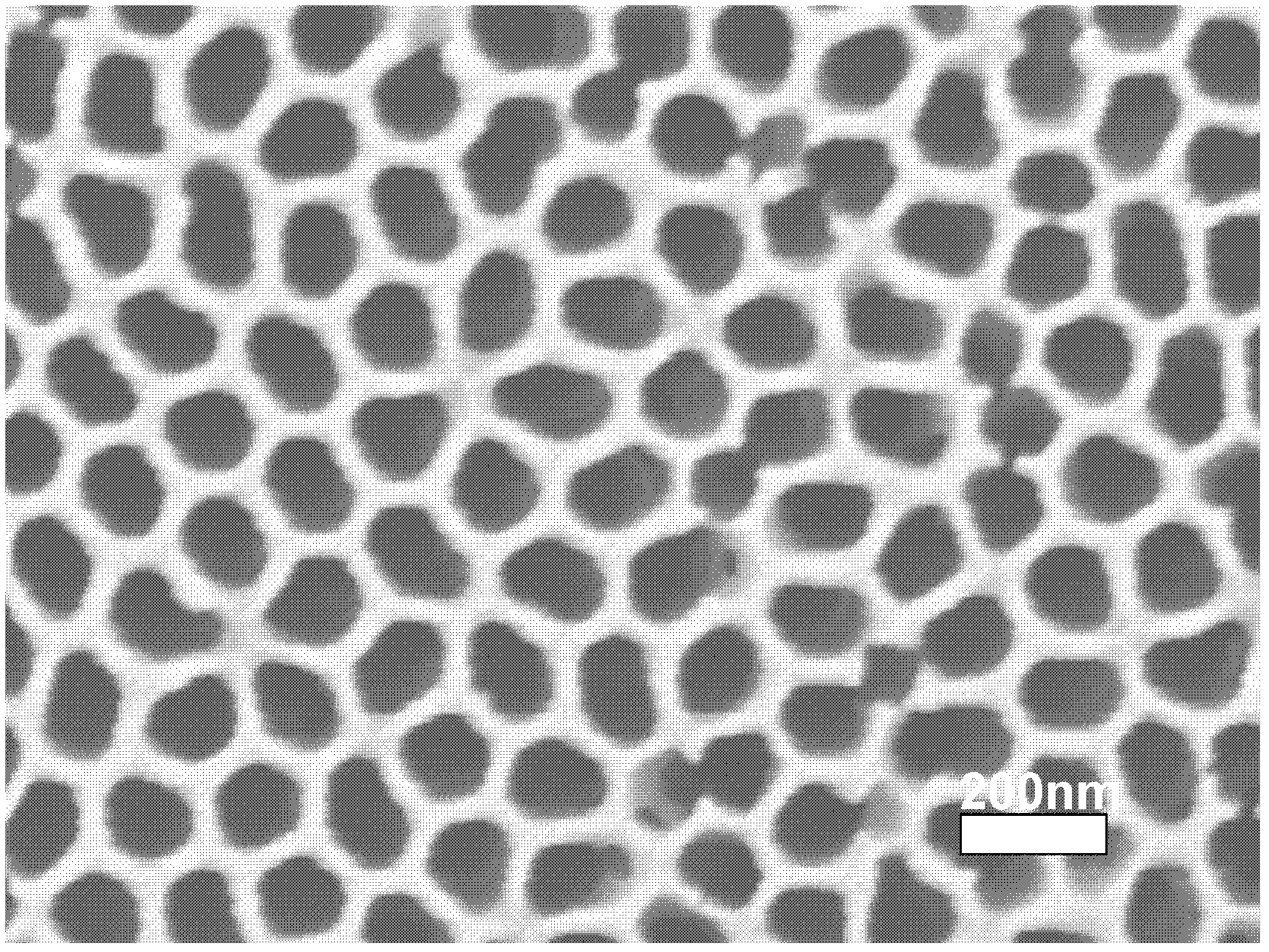

[0041] Clean anodized aluminum nanoporous film (the aperture of nanopore is 100nm, porosity 67% with clear water and ethanol cleaning, electron microscope picture is as follows image 3 As shown, the atomic force scanning diagram is shown as Figure 5 shown), then put it into dilute hydrochloric acid with a concentration of 5%, and clean the anodized aluminum nanoporous membrane at room temperature for 20-30 seconds, then rinse the surface of the anodized aluminum nanoporous membrane with water, and then wash the anodized aluminum nanoporous membrane The nanoporous membrane is placed in distilled water for 3-4 hours, then taken out and dried for later use.

[0042] The anodized aluminum oxide nanoporous membrane after cleaning and drying is placed in oxygen plasm...

Embodiment 2

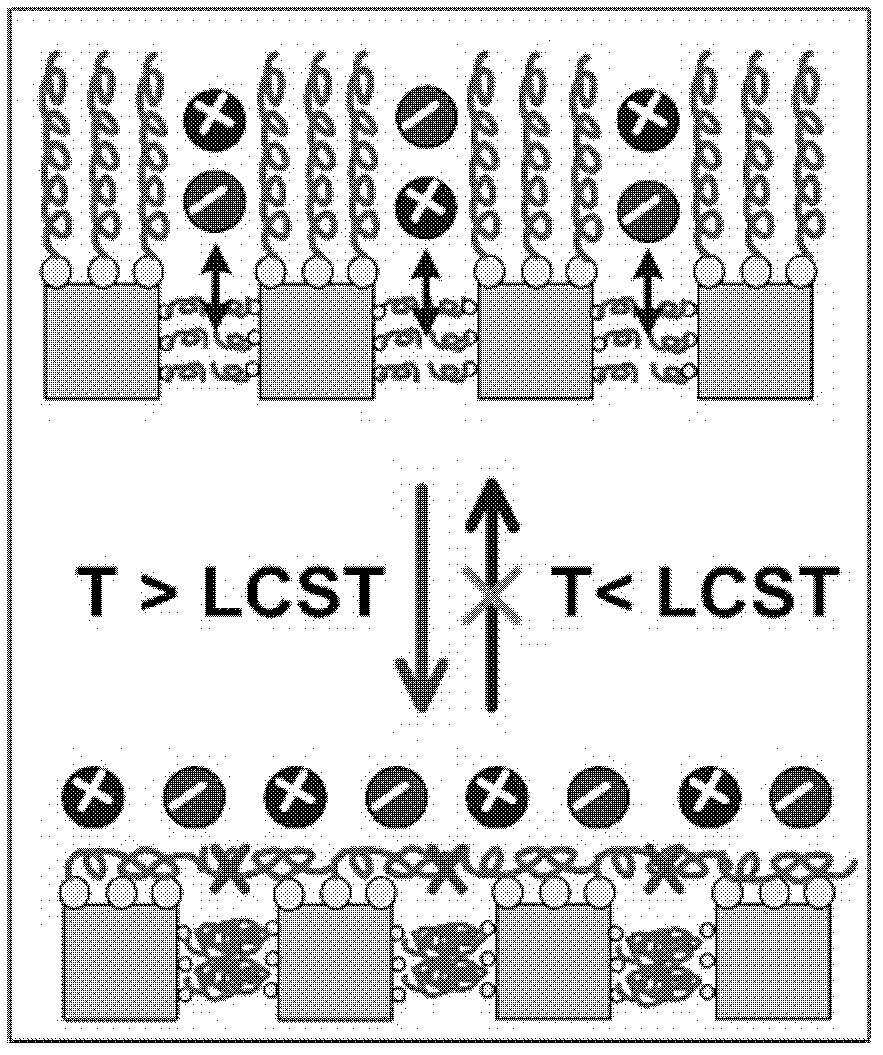

[0053] The preparation method is basically the same as in Example 1, except that 2 g of benzyl methacrylate monomer is added in the polymerization reaction of step 3).

[0054] In the electrolyte 1-ethyl-3-methylimidazoline bis(trifluoromethylsulfonyl)imide, when the temperature exceeds the minimum critical transition temperature of the polybenzyl methacrylate in the above electrolyte 140°C When (Table 1), the polybenzyl methacrylate will collapse in the nanopore channel of the anodized aluminum nanoporous membrane as the substrate and on the film, block the nanopore channel, and change The electrical conductivity of the anodized aluminum nanoporous membrane as the base; its electrical conductivity is 1 / 7 of the electrical conductivity of the anodized aluminum nanoporous membrane as the base.

[0055] The porosity of the anodized aluminum oxide nanoporous membrane with temperature-sensitive response properties is 18%.

Embodiment 3

[0057] The preparation method is basically the same as in Example 1, except that 3 g of monomers are added in the polymerization reaction of step 3).

[0058] In the electrolyte 1-ethyl-3-methylimidazoline bis(trifluoromethylsulfonyl)imide, when the temperature exceeds the minimum critical transition temperature of the polybenzyl methacrylate in the above electrolyte 151°C , the polybenzyl methacrylate will collapse in the nanopores of the anodized aluminum nanoporous membrane as the substrate and on the membrane, block the nanopores, and change the anode as the substrate The electrical conductivity of the aluminum oxide nanoporous membrane; its electrical conductivity is 1 / 6 of the electrical conductivity of the anodic aluminum oxide nanoporous membrane as the substrate.

[0059] The porosity of the anodized aluminum oxide nanoporous membrane with temperature-sensitive response properties is 20%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com