Modified diatom-ooze interior decorative material and production technique thereof

An interior decoration and diatom mud technology, which is applied in the field of modified diatom mud interior decoration materials, can solve the problems of powder or color fading, even mud, unsatisfactory adsorption, powder or color fading, etc., and saves money. Electric energy and heating costs, good thermal insulation performance, good breathing function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A diatom mud interior decoration material, which is composed of the following components in proportion by weight: 30% modified diatomite, 24% heavy calcium, 6% calcium hydroxide powder, 5% wood fiber, 3% rubber powder, Humectant 1%, meerschaum 22%, talc 9%.

Embodiment 2

[0025] A diatom mud interior decoration material, which is composed of the following components in proportion by weight: 31% modified diatomite, 23% heavy calcium, 5% calcium hydroxide powder, 6% wood fiber, 3.5% rubber powder, Humectant 1.5%, meerschaum 22%, talc 8%.

Embodiment 3

[0027] Modified diatomite 32%, heavy calcium 22%, calcium hydroxide powder 7%, wood fiber 4%, rubber powder 4%, humectant 1%, sepiolite wool 21.5%, talcum powder 8.5%.

[0028] In the above-mentioned embodiments, the modified diatomite is modified by adding sodium carbonate whose mass fraction is 5% of the diatomite raw diatomite after purification.

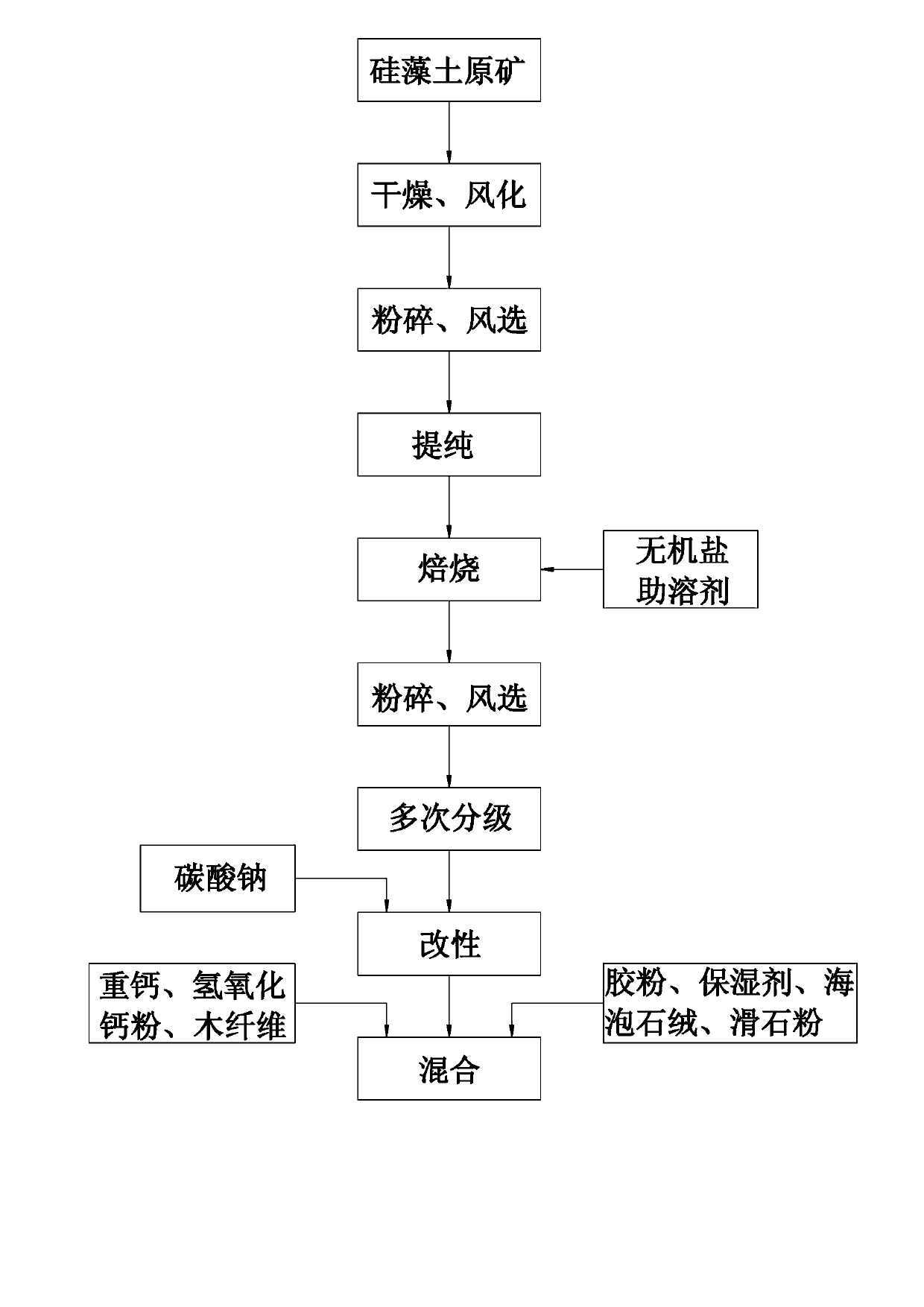

[0029] refer to figure 1 , the production process of the modified diatom mud interior decoration material, comprising the following steps:

[0030] 1. The diatomite raw ore is naturally dried and weathered, and the adobe is tested and sorted to grade, and transported to the processing workshop for crushing, winnowing, and purification;

[0031] 2. After purification, enter the high-temperature calcining kiln to add inorganic salt co-solvent for roasting;

[0032] 3. After crushing again, winnowing, and multiple classifications, add 5% sodium carbonate to modify at 900-1000°C to obtain modified diatomite;

[0033] 4. Weigh modi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com