Preparation method of condensation type beaded salicylic acid derivative boron-specific chelating resin

A technology of salicylic acid derivatives and chelating resins, which is applied in the ion exchange of chelates, chemical instruments and methods, ion exchange regeneration, etc., can solve the problems of low cost, difficult synthesis process, and few synthesis steps, and achieve Easy to implement, simple process, and conducive to large-scale promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

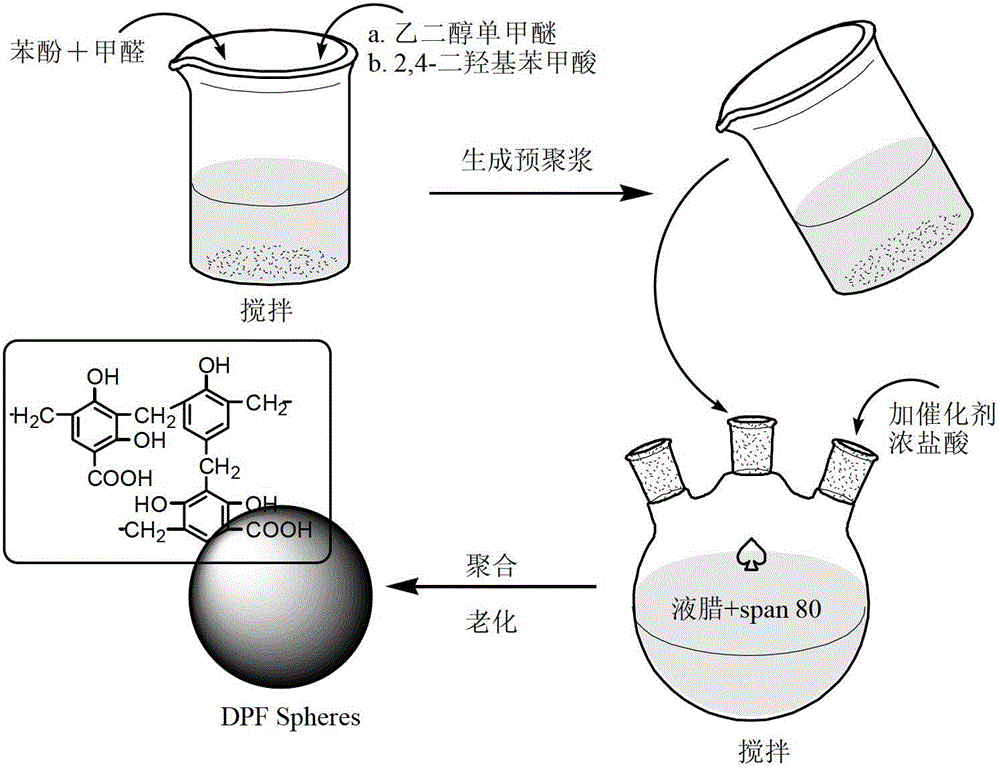

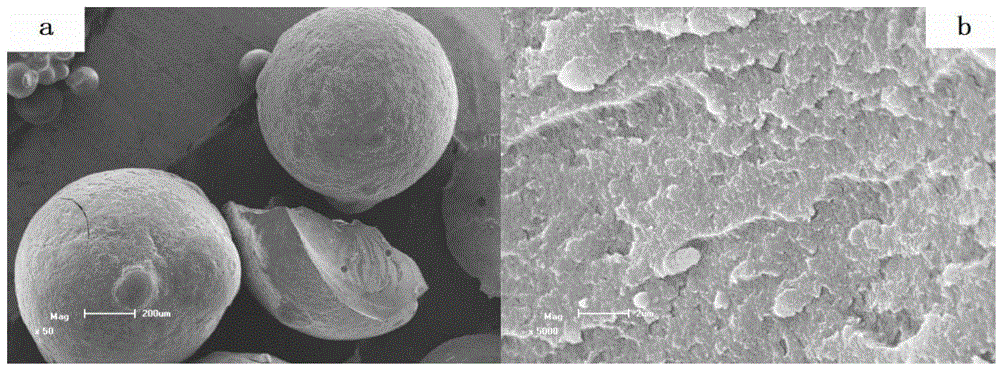

[0036] A preparation method of polycondensation type beaded salicylic acid derivative boron chelating resin. The boron chelating resin has two hydroxyl groups on the benzene ring, and uses 2,4-dihydroxybenzoic acid as a functional monomer and phenol It is a ternary copolymer resin (DPF Sphere) prepared by inverse suspension polycondensation method with concentrated hydrochloric acid (AR) as a catalyst, ethylene glycol or ethylene glycol monomethyl ether as a porogen, and the steps are as follows:

[0037] 1) Preparation of prepolymerized pulp:

[0038] At room temperature, 0.61g of phenol and 11.57g of a 38% by mass formaldehyde aqueous solution were mixed and stirred uniformly, and then reacted at 50±2oC for 2h to obtain a phenolic resin prepolymer. Add 10.0g2 to the prepolymer. 4-dihydroxybenzoic acid, 20g ethylene glycol, stir evenly to obtain prepolymerized slurry;

[0039] 2) Inverse suspension polycondensation reaction:

[0040] In a 500mL three-necked flask equipped with a st...

Embodiment 2

[0045] A preparation method of polycondensation type beaded salicylic acid derivative boron chelating resin. The ingredients and preparation steps are basically the same as those in Example 1, except that the dispersed phase is mixed with 150g liquid wax, 50g tetrachloroethylene and 2.15g Span80. Evenly composed. The boron adsorption capacity of the prepared resin was determined to be 1.18 mmol / g. .

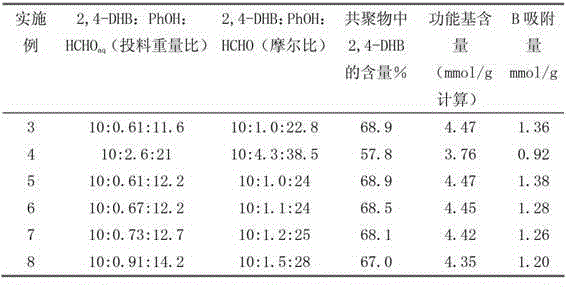

Embodiment 3-8

[0047] The preparation method of a group of polycondensation type beaded salicylic acid derivative boron chelating resin, ingredients and preparation steps are basically the same as in Example 1, except that the ratio of functional monomer to crosslinking agent is different, as shown in Table 1. The resin of Examples 3-8.

[0048] Table 1 Resins prepared by functional monomers 2,4-DHB, formaldehyde and different amounts of crosslinking agent phenol

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com