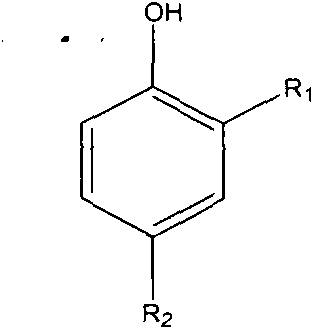

Modification method of xylene formaldehyde resin

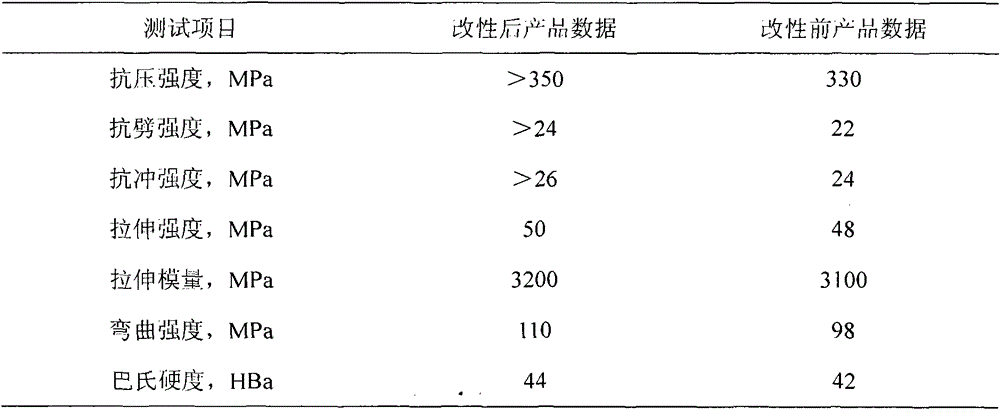

A technology of xylene formaldehyde resin and phenolic resin, which is used in the modification of thermoplastic plasticizers and the modification of xylene formaldehyde resin, can solve problems such as inability to cure and form, and achieve reduced crosslinking density, high mechanical strength, high The effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Phenol, formaldehyde and 0.075wt% methanesulfonic acid (calculated in xylene formaldehyde resin quality) join in the reactor with thermometer, stirring device and reflux condenser, and formaldehyde is that mass concentration is 37% formaldehyde aqueous solution, heating .To 80°C, react at constant temperature for 1 hour, then raise the temperature to 90°C, then react at constant temperature for 1 hour, then continue to heat up to 100°C, and react at constant temperature for 3 hours, then distill at atmospheric pressure, then heat up to 150°C and perform vacuum dehydration to obtain phenolic formaldehyde resin. Heat the obtained phenolic resin to 150° C., add xylene formaldehyde resin, and react at a constant temperature of 150° C. under vacuum for 1 hour to obtain a modified xylene formaldehyde resin.

Embodiment 2

[0032] Add xylene formaldehyde resin to a 1L 4-neck round bottom flask with stirring, water condenser, and thermocouple, then add a certain amount of phenol, and heat to 110°C. During the heating process, the viscosity of the mixture decreases, and the phenol gradually dissolves into xylene formaldehyde resin. 0.1 wt% p-toluenesulfonic acid (calculated based on the amount of xylene formaldehyde resin) was dissolved in 20% methanol solution, and then added to the above resin mixture. To prevent the temperature from rising, the catalyst was added dropwise. A few minutes after the addition of the catalyst, the water and formaldehyde solution began to reflux and the reaction temperature rose slightly due to the exotherm of the reaction. After the reaction started, the reaction temperature rose, and the reaction was carried out at 125° C. for about 45 minutes; after 45 minutes, the reaction temperature rose to 155° C., and the reaction was carried out at this temperature for 120 m...

Embodiment 3

[0034] Add quantitative xylene formaldehyde resin, hexanediol and 0.15wt% hydrochloric acid (calculated by xylene formaldehyde resin mass) into a 4-necked round-bottomed flask equipped with thermocouples, condenser tubes, etc., and heat to 110°C to boil and reflux to react For about 1 hour, cool down to 50°C; then add 37% formaldehyde solution, raise the temperature again to 110°C until boiling and reflux, and react for 1 hour; finally vacuumize and dehydrate. Add a small amount of curing agent hexamethylenetetramine to the obtained product, put it in an oven, heat cure at 140°C for 1 hour, and then cure at 160°C for 1 hour. After cooling, take it out and pulverize it, continue to dry for 3 hours, and cool to obtain the modified xylene formaldehyde resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com