Nano-particle and elastomer reinforcing and toughening polypropylene composite material and preparation method thereof

A technology of nanoparticles and composite materials, which is applied in the field of polypropylene composite materials reinforced and toughened by nanoparticles and elastomers and its preparation, can solve the problems that it is difficult to improve the mechanical properties and anti-aging properties of polypropylene materials at the same time, and achieve Effect of increasing Vicat heat distortion temperature, improving impact resistance and anti-aging performance, and expanding application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

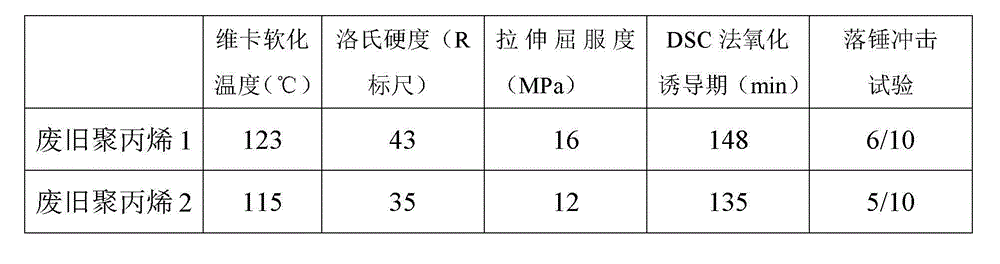

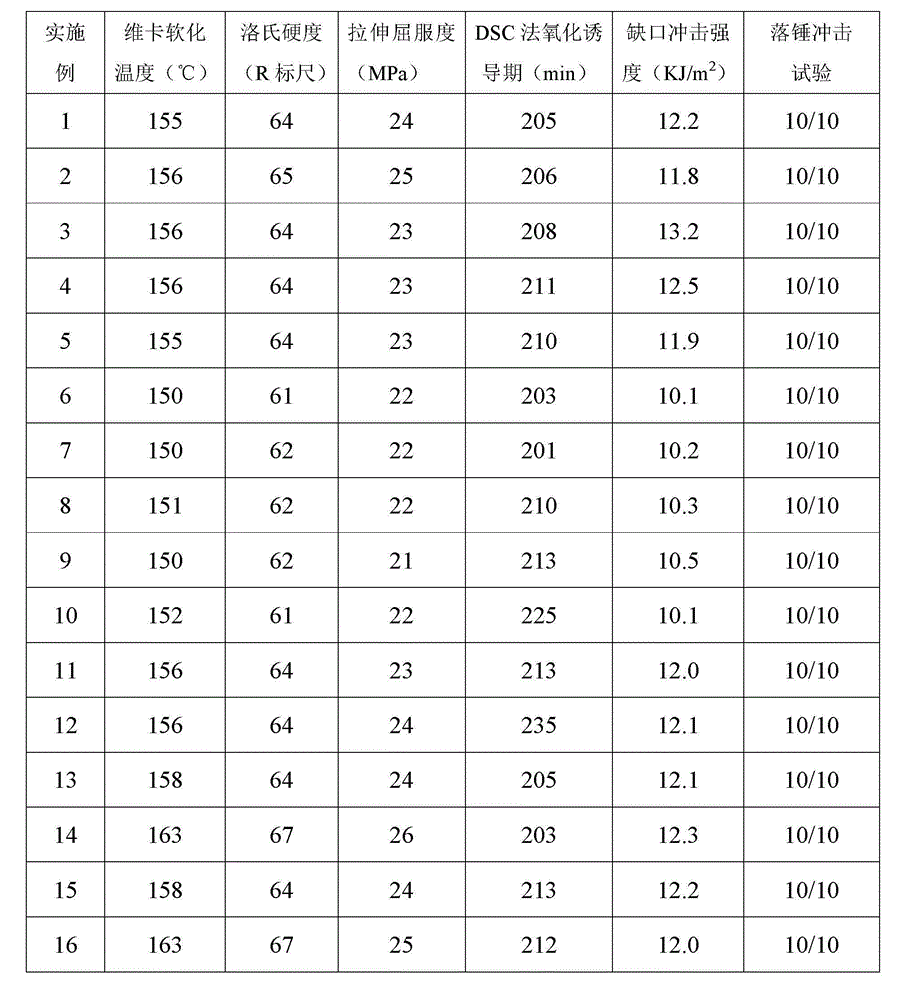

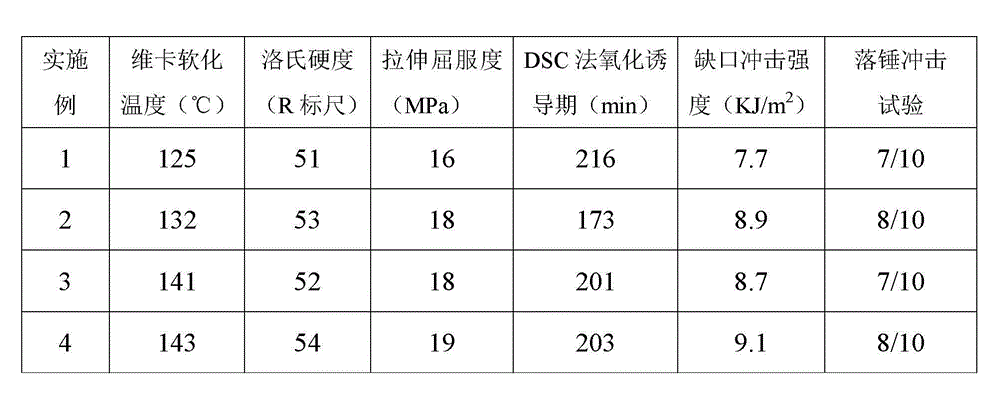

Examples

preparation example Construction

[0027] (1) Preparation of surface modified nanoparticles

[0028] Add nanoparticles, surfactants and optional organic antioxidants into a high-speed mixer at a mass ratio of 1.0:0.01-0.05:0-0.05, and stir for 50-100°C at a temperature of 80-150°C min, coating the surfactant on the nanoparticles to form surface-modified nanoparticles; the nanoparticles are composed of organic montmorillonite (OMMT), nano-titanium dioxide and nano-hydrotalcite (LDH);

[0029] (2) Preparation of maleic anhydride grafted polypropylene (PP-g-MAH)

[0030] Polypropylene, maleic anhydride and free radical initiator are mixed in a high-speed mixer according to the mass ratio of 1.0:0.1-0.2:0.01-0.02, melted and blended by a twin-screw extruder, and subjected to reactive extrusion. The extrusion temperature is 180 -230°C, the screw speed is 80-210 rpm to obtain maleic anhydride grafted polypropylene;

[0031] (3) Preparation of polypropylene composite materials

[0032] The surface-modified nanopart...

Embodiment 1

[0039] Step 1: Add nanoparticles with an average particle size of 5-100nm and oleic acid into a high-speed mixer at a mass ratio of 1.0:0.02, and stir for 50-100 minutes at a temperature of 100-120°C to form a surface Modified nanoparticles; the nanoparticles are composed of 40wt% OMMT, 30wt% nano-titanium dioxide, 30wt% LDH; second step: isotactic polypropylene, maleic anhydride and dicumyl peroxide according to 1.0 The mass ratio of 0.1:0.01 is mixed by a high-speed mixer, melted and blended by a twin-screw extruder, and subjected to reactive extrusion. The extrusion temperature is 180-230 ° C, and the screw speed is 80-210 rpm to obtain maleic anhydride grafted Polypropylene; the third step: the surface-modified nanoparticles obtained in the first step, the maleic anhydride grafted polypropylene (PP-g-HAM) obtained in the second step, ethylene-propylene-diene rubber (EPDM) and ethylene- Octene copolymer (POE) and waste polypropylene 1 are mixed in a high-speed mixer accordi...

Embodiment 2

[0041] Step 1: Add nanoparticles with an average particle size of 5-100nm and oleic acid into a high-speed mixer at a mass ratio of 1.0:0.05, and stir for 75-100 minutes at a temperature of 120-150°C to form a surface Modified nanoparticles; the nanoparticles are made up of 50wt% OMMT, 25wt% nano-titanium dioxide, 25wt% LDH; the second step: isotactic polypropylene, maleic anhydride and dicumyl peroxide according to 1.0 The mass ratio of 0.2:0.02 is mixed by a high-speed mixer, melted and blended by a twin-screw extruder, and subjected to reactive extrusion. The extrusion temperature is 180-230 ° C, and the screw speed is 80-210 rpm to obtain maleic anhydride grafted Polypropylene; the third step: the surface-modified nanoparticles obtained in the first step, the maleic anhydride grafted polypropylene (PP-g-HAM) obtained in the second step, ethylene-propylene-diene rubber (EPDM) and ethylene- Octene copolymer (POE) and waste polypropylene 1 are mixed in a high-speed mixer acco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| Rockwell hardness | aaaaa | aaaaa |

| tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com