Method of dynamically preparing special-shaped cavity bacterial cellulose (BC) materials

A bacterial cellulose and cavity technology, which is applied in the field of dynamic preparation of special-shaped cavity bacterial cellulose materials, can solve problems such as inability to carry out industrial production and application, low production efficiency, and long production cycle, and achieve good application prospects and high production efficiency. High, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1. Design and assembly of fermentation equipment

[0054] 1.1 Design thinking

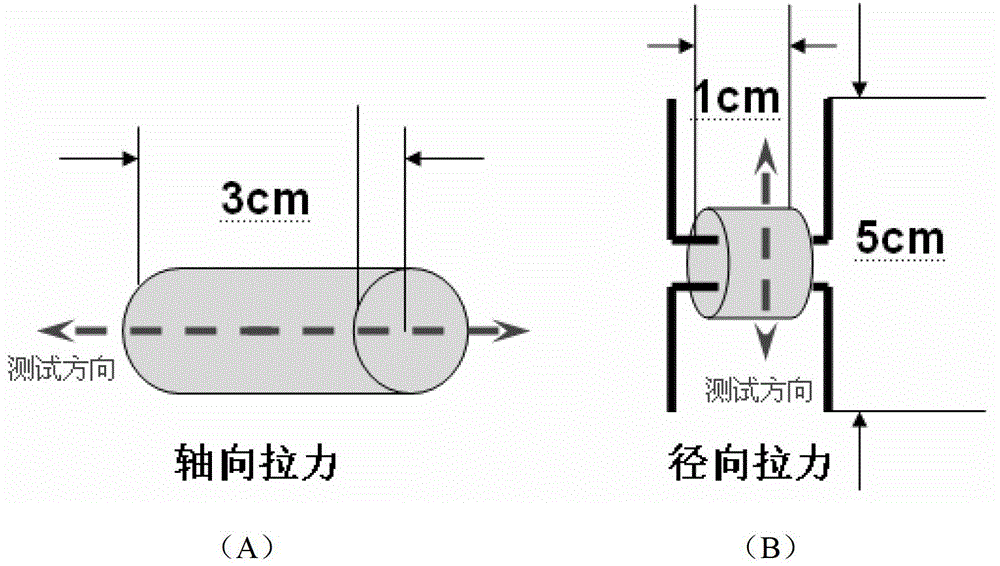

[0055] Since Acetobacter xylinum is an aerobic bacterium, it needs a large amount of oxygen in the long-term fermentation and metabolism process. The growth of bacterial cellulose is an adsorption growth and must be supported by a medium. Therefore, it is necessary to let the bacterial cellulose grow in a certain shape To be formed, bacterial cellulose must be grown aerobically on a mold material of a specific shape. If the bacterial cellulose material to be prepared is a tubular material, stick-shaped, rod-shaped or tubular molds should be considered, not only to allow the bacterial cellulose to grow on these molds, but also to provide sufficient oxygen. For this reason, we have designed a A horizontal bioreactor equipped with a stick-shaped mold, which allows the mold to be slowly circulated and repeatedly submerged in the liquid medium for disturbed culture, so that the bacterial cellulo...

Embodiment 2

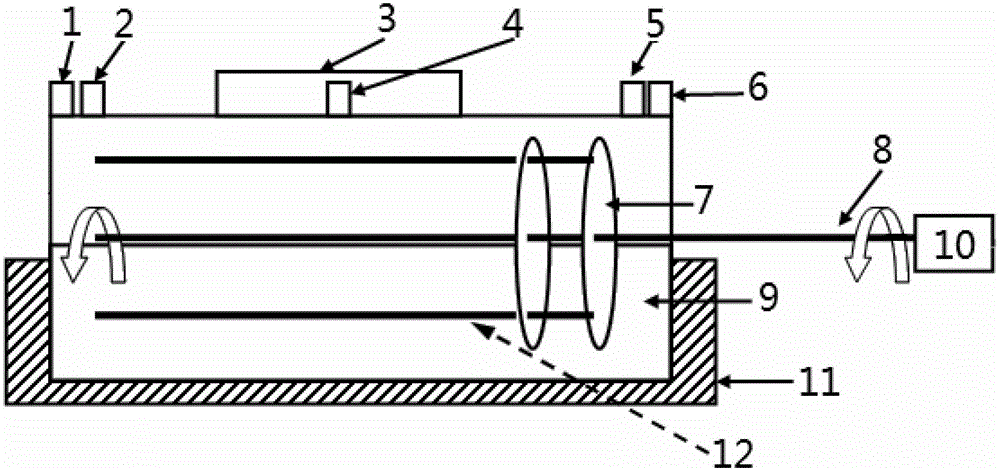

[0064] Such as Figure 1a , Figure 1b As shown, a device for dynamically preparing bacterial cellulose materials with special-shaped cavities, a simple and efficient fermentation device for dynamically producing bacterial cellulose materials with special-shaped cavities, including a thermometer port 1, an acid and alkali liquid addition port 2, a handle 3, Ventilation port 4, pH meter port 5, nutrient feeding port 6, rotating shaft 8, fermentation tank 9, motor 10, water bath device 11, mold, characterized in that: one end of the rotating shaft 8 is connected to the output shaft of the fixed motor 10, and the rotating shaft 8 The other end extends into the fermenter 9 from the central position of one end face of the fermenter 9; a mold is fixed on the rotating shaft 8 in the fermenter 9.

[0065] The material of mold 12 is selected from glass, pottery, purple sand, metal, silica gel, wood, cellulose, rubber, polyester, nylon, Orlon, polyvinyl alcohol, polyvinyl alcohol, polye...

Embodiment 3

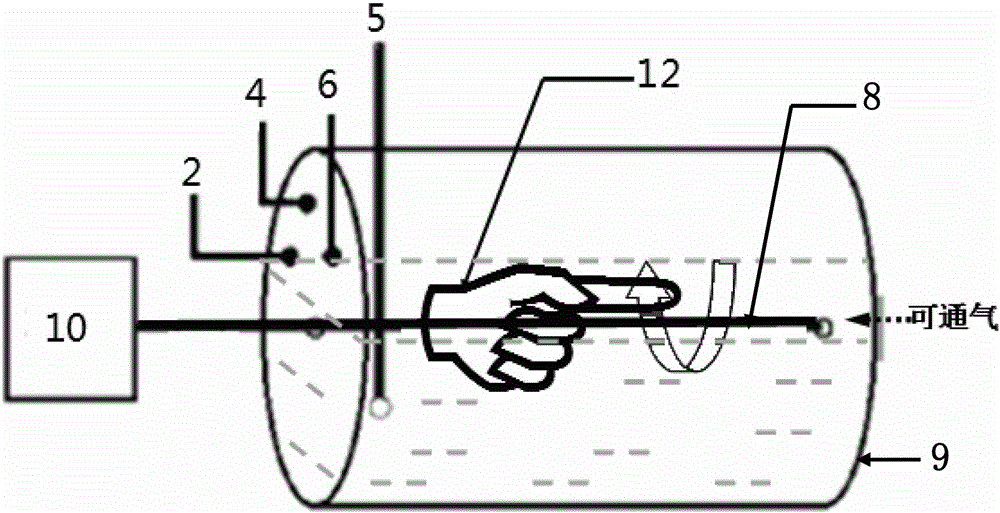

[0071] Such as figure 2 As shown, the difference between this embodiment and embodiment 2 only lies in:

[0072] (1) The shape of the mold is different. In this embodiment, the mold is a glove-shaped mold 12, and the glove-shaped mold 12 is a solid or hollow structure. The cross-sectional shape of the glove-shaped mold 12 is circular, square, oval, triangle, heart shape or pentagram;

[0073] (2) In the device of this embodiment, there is no need for a turntable to fix the glove-shaped mold, and it is only necessary to insert more than one glove-shaped mold in sequence on the rotating shaft.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com