Composite material with conductive and ferromagnetic properties and hybrid slurry

A composite material, ferromagnetic technology, applied in the direction of ferrous oxide, nanotechnology for materials and surface science, adhesive type, etc., can solve the problem of insufficient ferromagnetism or conductivity of nanocomposite materials, composite materials It is not easy to disperse and process, and achieve the best electromagnetic wave protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] [Example 1] Synthesis of columnar nano iron oxide

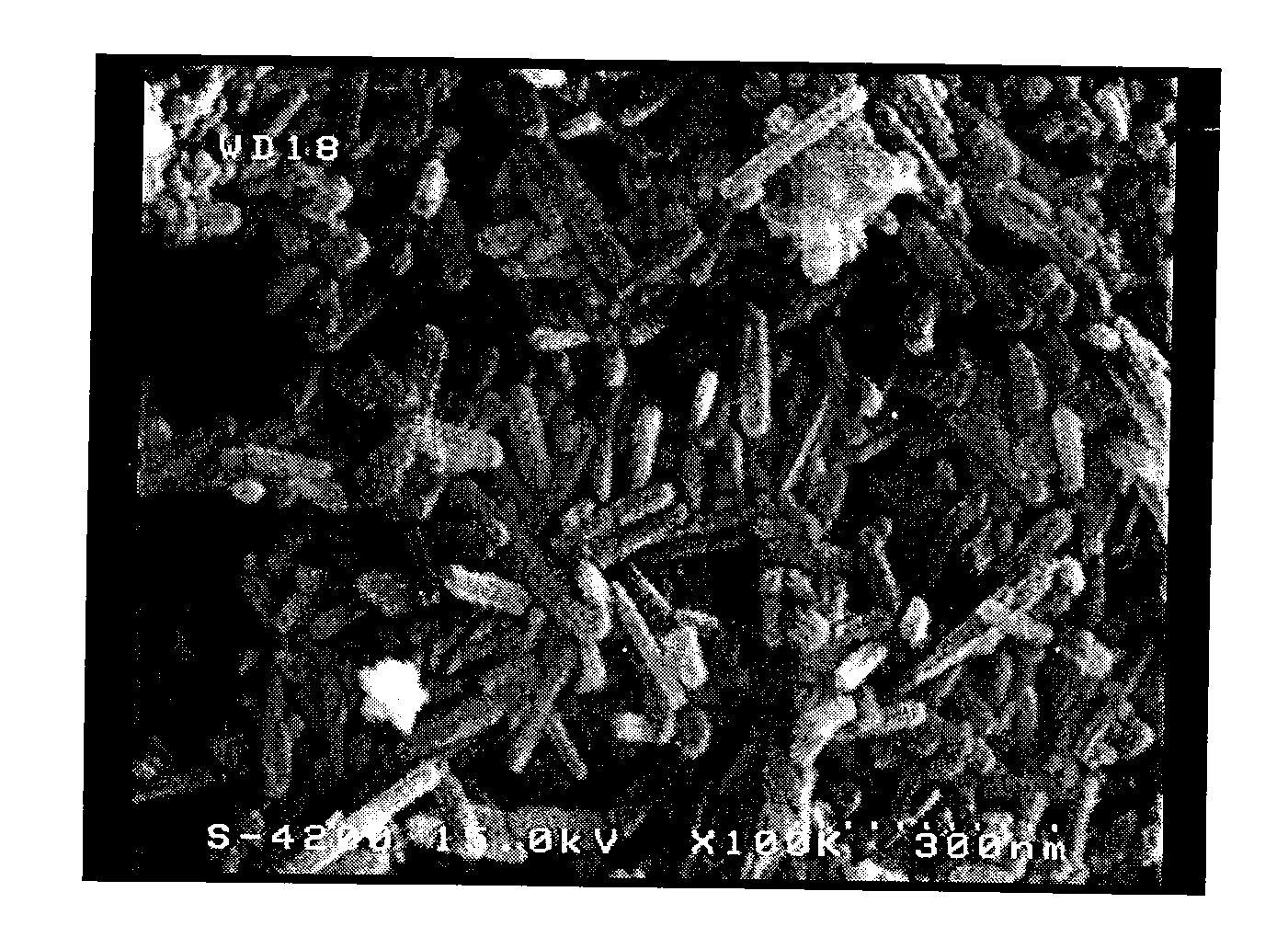

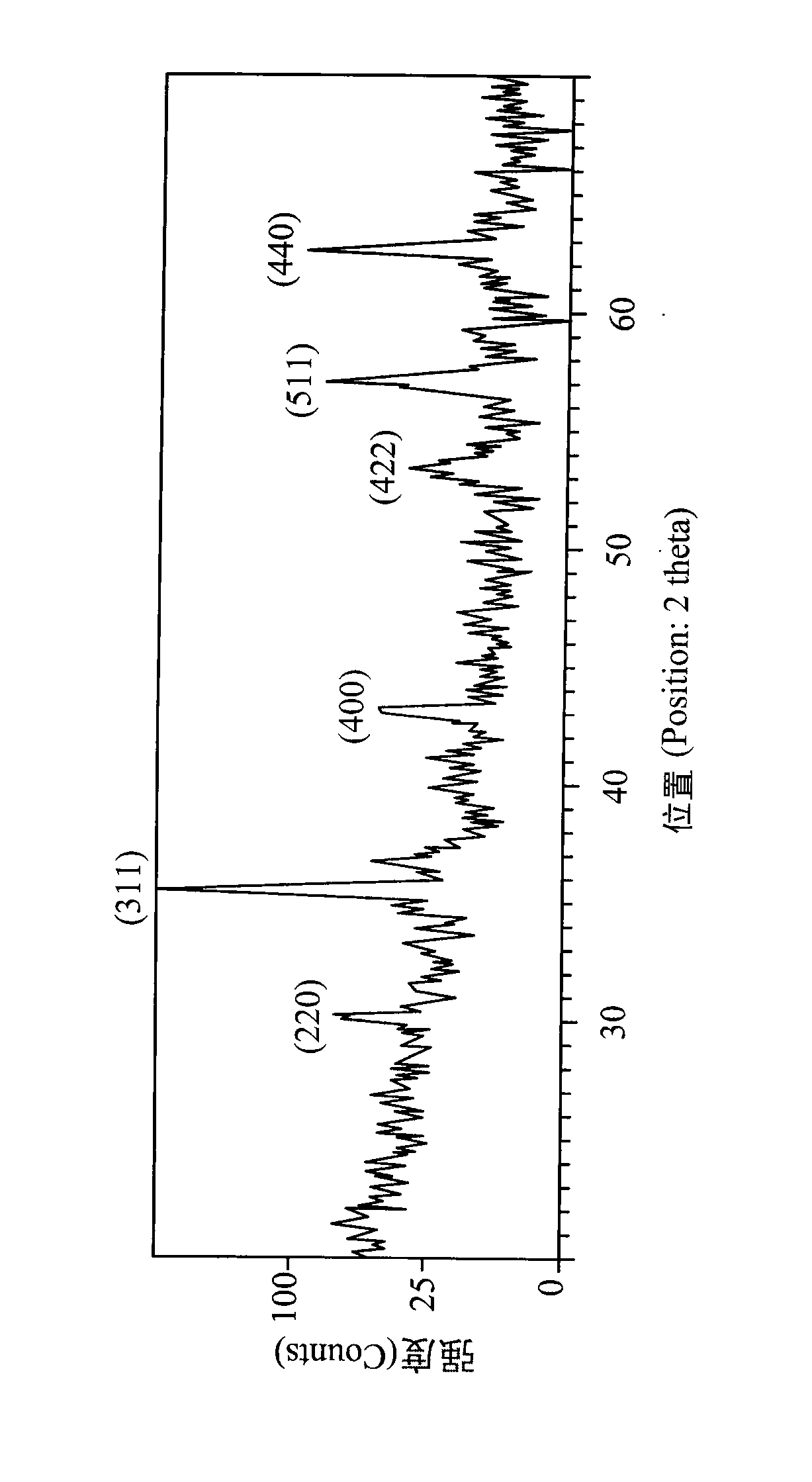

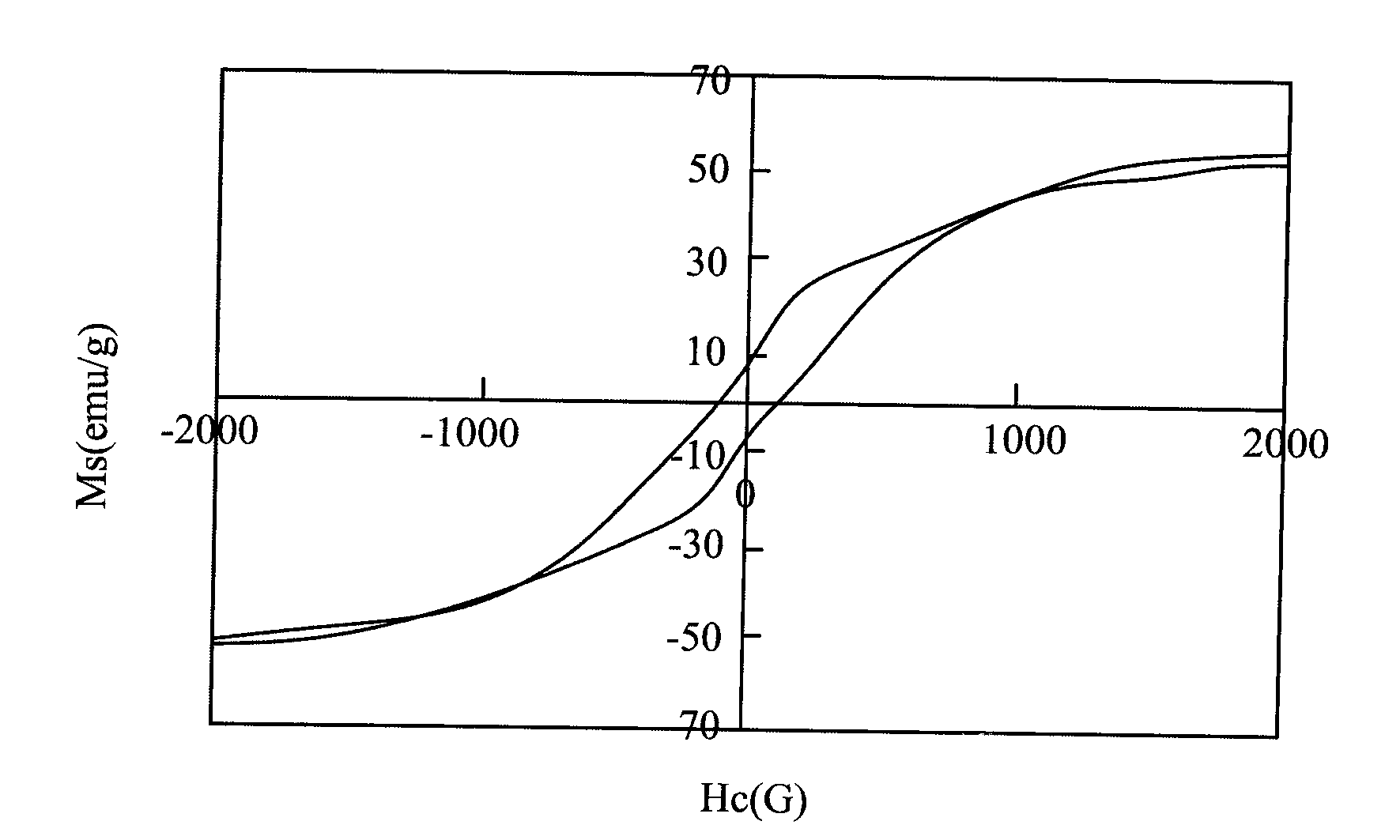

[0037] 0.648 g FeCl 3 Dissolve in 80ml of water, then add 0.556 grams of ferrous sulfate (FeSO 4 ·7H 2 O) and stir to dissolve. After dissolving, add 40ml of toluene (Toluene) under nitrogen, then slowly add 10ml (20mM) of cetyltrimethylammonium bromide (CTAB; cetyltrimethylammonium bromide) and 10ml of ethylenediamine (ethylenediamine) as a surfactant , after stirring for 20 minutes, react at 120° C. for 20 hours. Then, the sample is taken out and washed with pure water, and then the particles are dispersed in the aqueous solution using an ultrasonic oscillator. The shape of the synthesized iron oxide was analyzed by scanning electron microscope (SEM; scanning electron microscope), transmission electron microscope (TEM; Transmission electron microscopy) and X-ray diffraction (XRD; X-ray scattering techniques) , particle size and composition.

[0038] figure 1 SEM images showing the formed columnar nano-iron oxi...

Embodiment 2

[0041] [Example 2] Synthesis of columnar nano-iron oxide with conductive polymer shell

[0042] Take 0.04 g of nano columnar iron oxide synthesized in Example 1, put it into water, add 40 μl of aniline (aniline) and stir. At the same time, 0.328 g of ammonium persulfate (APS; Ammonium persulfate) was dissolved in 0.01 M hydrochloric acid solution as an initiator. Then, slowly add ammonium persulfate solution in the reaction solution, and keep stirring and keep the ice bath for 6 hours, after the reaction, ferric iron tetroxide (Fe 3 o 4 ) / polyaniline (PANi; polyaniline) core-shell particles. Wash with pure water and then disperse it in water. The core-shell structure of the synthesized ferric oxide / polyaniline particles was analyzed by TEM. refer to Figure 4 It can be found that the inner layer of the particles is darker iron oxide, and the outer layer is covered with a very thin layer of paler polyaniline. This is because the electron density of polyaniline is lower th...

Embodiment 3

[0044] [Example 3] Preparation of mixed slurry-B

[0045] The columnar nano-iron oxide synthesized in Example 1 and dispersed in water, an appropriate proportion of conductive polymer and 1 wt% polyvinyl alcohol (PVA; polyvinyl alcohol) were mixed. Among them, the conductive polymer used is poly(3,4-ethylenedioxythiophene)-polystyrenesulfonic acid (PEDOT:PSS; Poly(3,4-ethylenedioxythiophene):poly(styrenesulfonate); purchased from Quanhong ). Vibrate the above mixture with an ultrasonic oscillator for 30 minutes, and then continue stirring for about 18 hours to make it evenly mixed to obtain a mixed slurry.

[0046] Be formulated with the mixed slurry that has three kinds of different columnar nano-iron oxide contents according to the above-mentioned method, wherein the content of columnar nano-iron oxide is respectively 1.2wt% (B 1 ), 6wt% (B 2 ), 12wt% (B 3 ).

[0047] Measure the conductivity (Conductivity) of each slurry with conductivity meter respectively, it is 1040...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com