A method for growing bife1‐xcoxo3 series crystals

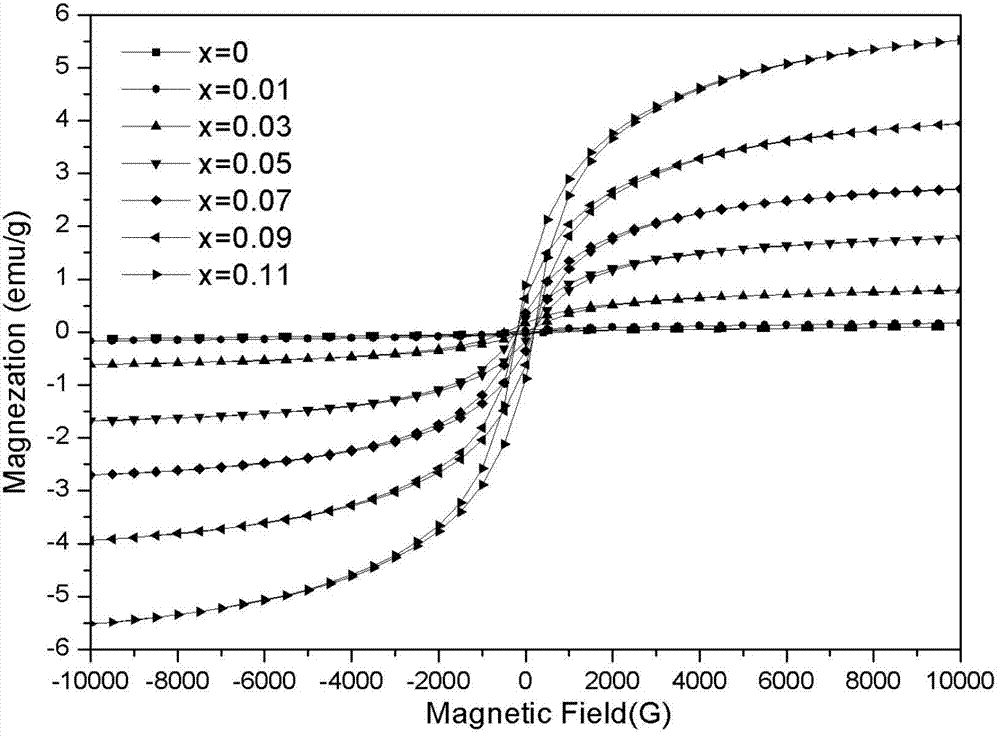

A bife1-xcoxo3, fe2o3 technology, applied in the field of growing BiFe1‐xCoxO3 series crystals, can solve the problem of invisible ferromagnetism, and achieve the effect of suppressing the generation of miscellaneous items, fast growth, and eliminating potential pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

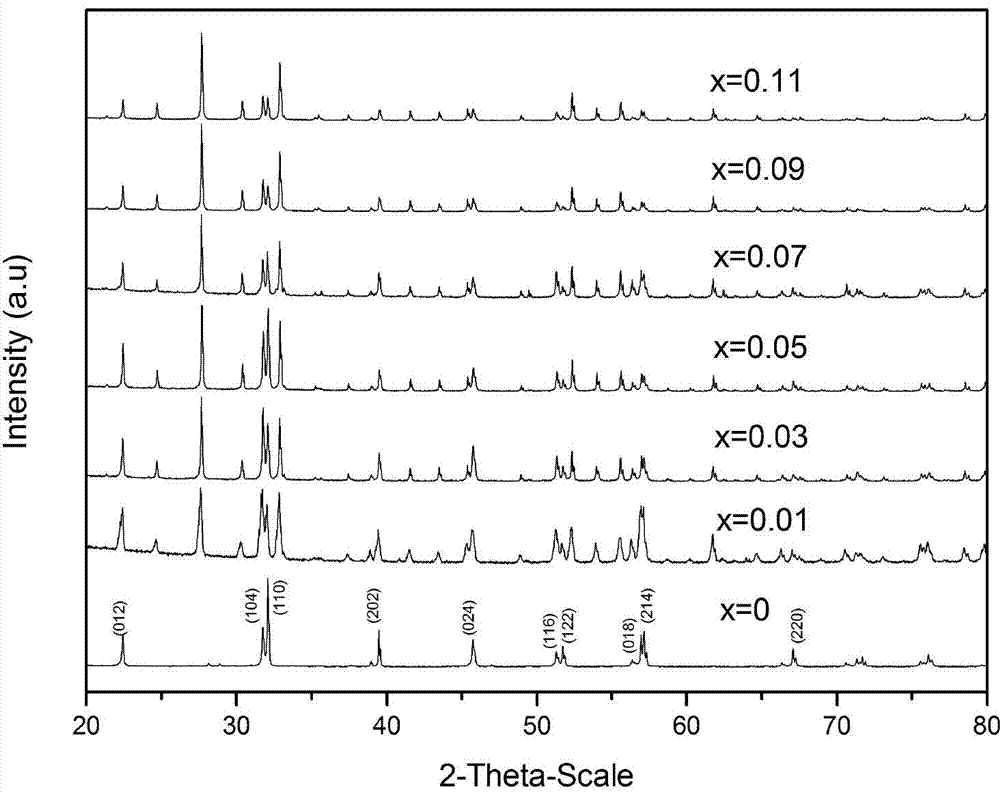

[0022] (1) The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method single crystal growth furnace produced by Japan Crystal Systems Corporation, and what grows is BiFe 0.99 co 0.01 o 3 series of crystals.

[0023] Powder Fe 2 o 3 (99.99%), Bi 2 o 3 (99.99%) and CoO (99.99%) by BiFe 0.99 co 0.01 o 3 Stoichiometric ratio was weighed, placed in a ZrO 2 In the nylon tank of the grinding medium, use absolute ethanol as the dispersant for ball milling, drying, and then put the powder into Al 2 o 3 In the crucible, it was pre-fired at 850°C for 1 hour with a silicon-molybdenum furnace, crushed and sieved with 80 mesh, then ball milled, dried, and sieved with 200 mesh. Get BiFe 0.99 co 0.01 o 3 Powder.

[0024] (2) Put the powder prepared in step (1) into a long rubber balloon, compact and seal it, vacuumize it for 10 minutes, and make a green bar with uniform thickness and density under 65MPa isostatic pressure. ...

Embodiment 2

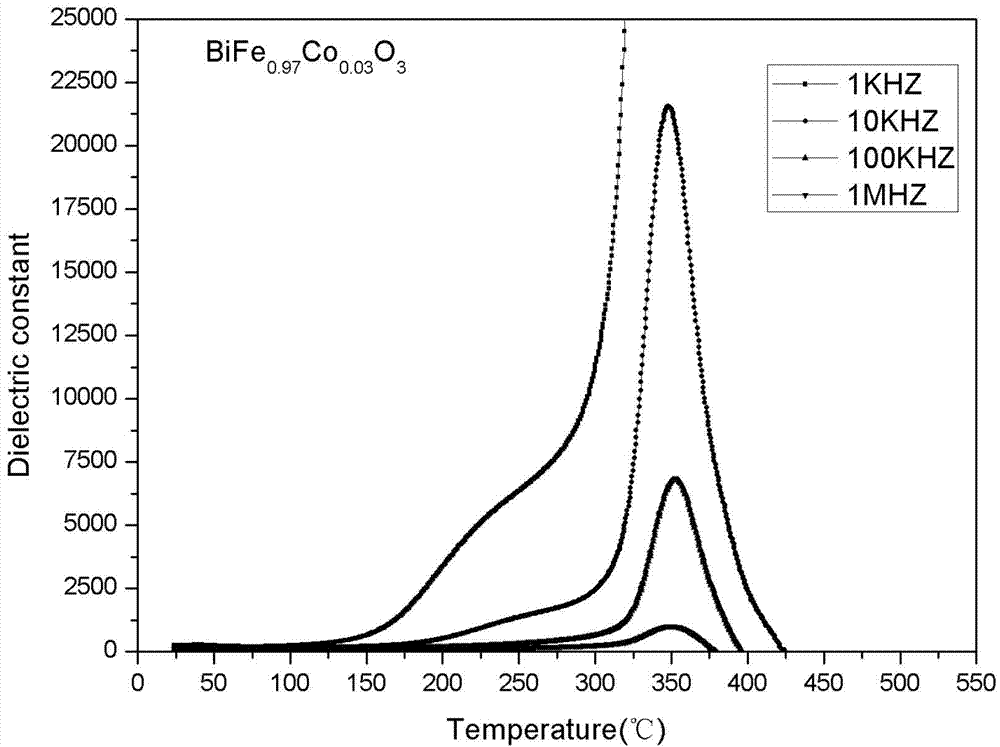

[0028] (1) The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method single crystal growth furnace produced by Japan Crystal Systems Corporation, and what grows is BiFe 0.97 co 0.03 o 3 series of crystals.

[0029] Powder Fe 2 o 3(99.99%), Bi 2 o 3 (99.99%) and CoO (99.99%) by BiFe 0.97 co 0.03 o 3 Stoichiometric ratio was weighed, placed in a ZrO 2 In the nylon tank of the grinding medium, use absolute ethanol as the dispersant for ball milling, drying, and then put the powder into Al 2 o 3 In the crucible, it was pre-fired at 845°C for 1 hour in a silicon-molybdenum furnace, crushed and sieved to 80 mesh, then ball milled, dried, and sieved to 200 mesh. Get BiFe 0.97 co 0.03 o 3 Powder.

[0030] (2) Put the powder prepared in step (1) into a long rubber balloon, compact and seal, vacuumize for 10 minutes, and make a green bar with uniform thickness and density under 65MPa isostatic pressure.

[0031] (3)...

Embodiment 3

[0034] (1) The crystal growth furnace used in the present invention is the FZ-T-10000-VI-VPO-PC optical floating zone method single crystal growth furnace produced by Japan Crystal Systems Corporation, and what grows is BiFe 0.95 co 0.05 o 3 series of crystals.

[0035] Powder Fe 2 o 3 (99.99%), Bi 2 o 3 (99.99%) and CoO (99.99%) by BiFe 0.95 co 0.05 o 3 Stoichiometric ratio was weighed, placed in a ZrO 2 In the nylon tank of the grinding medium, use absolute ethanol as the dispersant for ball milling, drying, and then put the powder into Al 2 o 3 In the crucible, it is pre-fired at 840°C for 1 hour with a silicon-molybdenum furnace, crushed and sieved with 80 mesh, then ball milled, dried, and sieved with 200 mesh. Get BiFe 0.95 co 0.05 o 3 Powder.

[0036] (2) Put the powder prepared in step (1) into a long rubber balloon, compact and seal, vacuumize for 15 minutes, and make a green bar with uniform thickness and density under 65MPa isostatic pressure.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com