Method for modifying polyester fabric by using magnetic nanometer iron oxide

A technology of triiron tetroxide and polyester fabrics, applied in the directions of physical treatment, textile and papermaking, fiber type, etc., it can solve the problems of poor hand feel and air permeability, no or weak magnetic properties, and poor washing performance, and achieves strong adhesion. The effect of good degree, easy operation and strong magnetic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

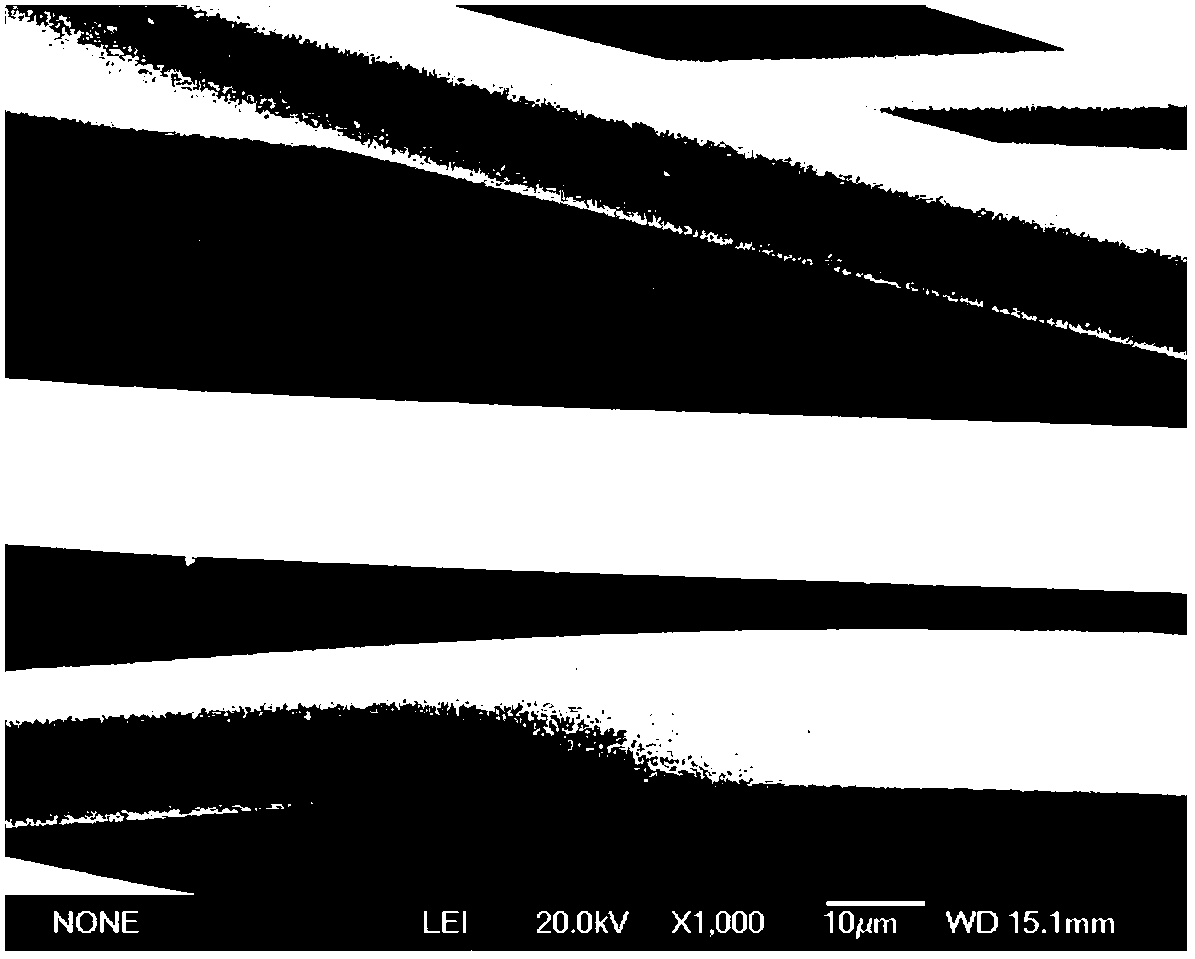

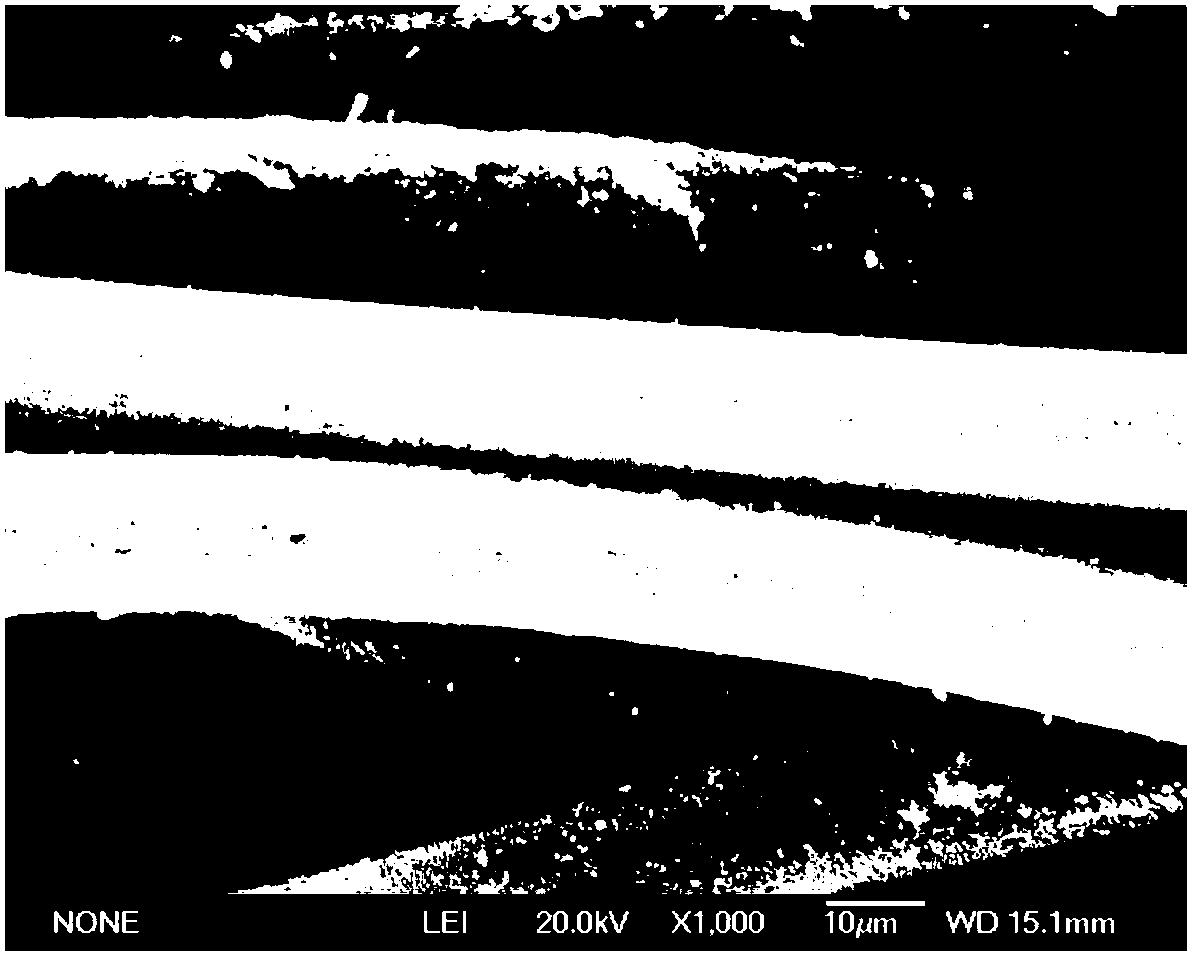

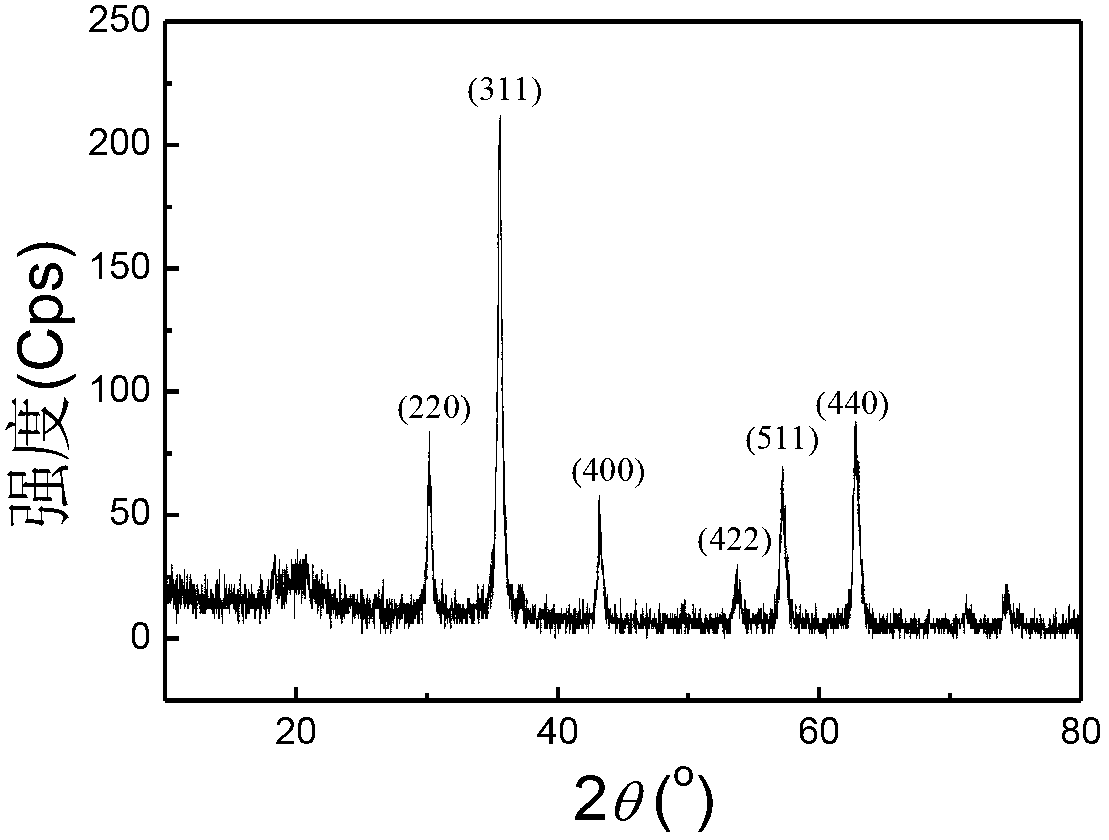

Embodiment 1

[0067] Prepare a sodium hydroxide solution with a mass concentration of 160g / L, weigh 10g of polyester fabric, soak the polyester fabric in 500mL of sodium hydroxide solution at a bath ratio of 1:50, treat it at 80°C for 20min, and then use After cleaning with water ethanol and deionized water, dry at 80°C for 20 minutes to dry the pretreated polyester fabric; measure 300mL of deionized water according to the quality of the pretreated polyester fabric with a bath ratio of 1:30, According to the total iron concentration of 0.03mol / L, the molar ratio of ferrous ions to hydroxide is 1:4, respectively weigh ferrous sulfate and sodium hydroxide, and dissolve ferrous sulfate in deionized water to obtain ferrous sulfate solution , then add sodium hydroxide and fully stir to obtain a mixed solution of ferrous sulfate and sodium hydroxide, according to the mixed solution of 2g of nickel sulfate, 10g of cetyltrimethylammonium bromide, 3g of chitosan Add the weighed nickel sulfate, cetyl...

Embodiment 2

[0070] Prepare a sodium hydroxide solution with a mass concentration of 200g / L, weigh 10g of polyester fabric, soak the polyester fabric in 800mL of sodium hydroxide solution at a bath ratio of 1:80, treat it at 100°C for 40min, and then use After cleaning with water ethanol and deionized water, dry at 100°C for 40 minutes to dry the pretreated polyester fabric; measure 600mL of deionized Water, according to the total iron concentration of 0.1mol / L, the molar ratio of ferrous ions and hydroxide radicals is 1:8, respectively weigh ferrous sulfate and sodium hydroxide, dissolve the weighed ferrous sulfate in deionized water, Obtain ferrous sulfate solution, then add sodium hydroxide and fully stir, obtain ferrous sulfate and sodium hydroxide mixed solution, add the nickel sulfate of 4g according to every liter of mixed solution, the hexadecyltrimethylammonium bromide of 20g , the proportion of chitosan of 6g is weighed, nickel sulfate, cetyltrimethylammonium bromide and chitosan...

Embodiment 3

[0073] Prepare a sodium hydroxide solution with a mass concentration of 180g / L, weigh 10g of polyester fabric, soak the polyester fabric in 600mL of sodium hydroxide solution at a bath ratio of 1:60, treat it at 90°C for 30min, and then use After cleaning with water, ethanol and deionized water, dry at 90°C for 30 minutes to dry the pretreated polyester fabric; measure 400mL of deionized water according to the quality of the pretreated polyester fabric with a bath ratio of 1:40 According to the total iron concentration of 0.08mol / L, the molar ratio of ferrous ions to hydroxide is 1:6, respectively weigh ferrous sulfate and sodium hydroxide, and dissolve ferrous sulfate in deionized water to obtain ferrous sulfate solution, then add sodium hydroxide and fully stir to obtain a mixed solution of ferrous sulfate and sodium hydroxide, add 4g of nickel sulfate, 20g of cetyltrimethylammonium bromide, and 6g of shell The proportion of polysaccharides was weighed, and the weighed nicke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com