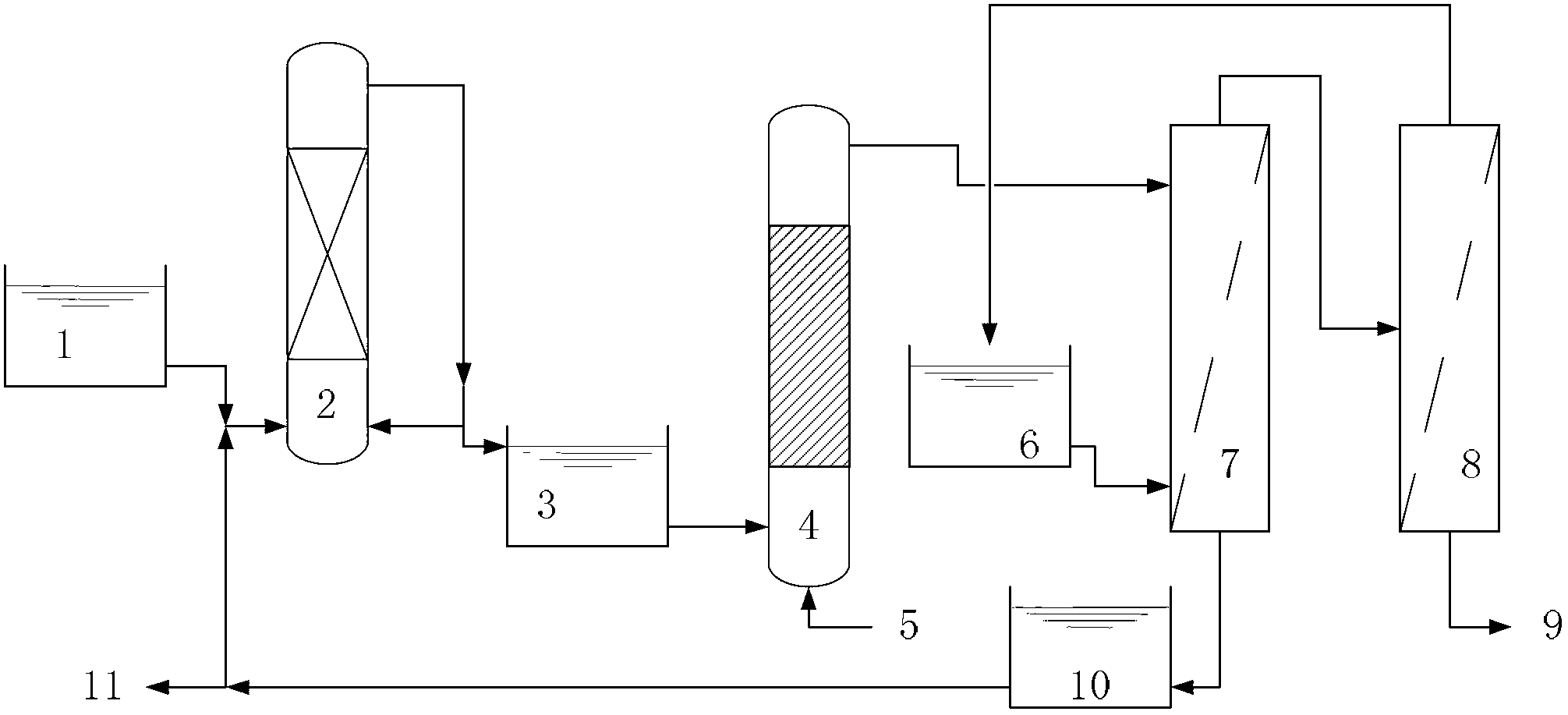

Method and device for recovery and purifying elemental sulfur from high-concentration sulfate wastewater

A sulfate and high-concentration technology, applied in chemical instruments and methods, sulfur preparation/purification, water/sewage multi-stage treatment, etc., can solve problems such as difficult separation of sulfur, achieve high recovery efficiency, good economy, and industrial Apply Promising Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The waste water to be treated is the mixed waste water after stripping and deamination of the monosodium glutamate plant, and its main indicators are: pH: 8.0~8.5; COD: 11000~13000mg / L; SO4 2- : 8000~12000mg / L; NH 3 -N: 200-300mg / L.

[0058] In the actual treatment of wastewater, the reflux ratio of the treated wastewater is 3:1. After conditioning, the SO in the wastewater 4 2- The concentration is 4g / L; COD:SO 4 2- is 1.7; the reaction time (hydraulic retention time HRT) of the anaerobic biological treatment stage is controlled at 15h, the reaction temperature is controlled at 35±0.5°C, and the effluent SO in the anaerobic biological reduction stage 4 2- The concentration is lower than 400mg / L; the reaction time (hydraulic retention time HRT) of the aerobic biological treatment stage is controlled at 1.5h, the reaction temperature is controlled at 30±1°C, and the oxidation-reduction potential is -75mV; the extraction agent is chlorostyrene and kerosene Mixture, ...

Embodiment 2

[0060] The wastewater to be treated is the wastewater produced by the fine desulfurization of flue gas desulfurization tail gas in power plants, and its main indicators are: pH: 7.8-8.2; COD: 2- : 18000~25000mg / L; Na + : 20000~300000mg / L.

[0061] In the actual treatment of wastewater, the reflux ratio of the treated wastewater is 7:1. After conditioning, the SO in the wastewater 4 2- The concentration is 4.2g / L; COD:SO 4 2- 1.5; industrial ethanol is added to supplement the organic substrate of wastewater during wastewater conditioning; the reaction time (hydraulic retention time HRT) of the anaerobic biological treatment stage is controlled at 15h, the temperature is controlled at 35±0.5°C, and the effluent of the anaerobic biological reduction stage SO 4 2- The concentration is lower than 400mg / L; the reaction time (hydraulic retention time HRT) of the aerobic biological treatment stage is controlled at 2h, the temperature is controlled at 30±1°C, and the oxidation-red...

Embodiment 3

[0063] The wastewater to be treated is antibiotic wastewater from a pharmaceutical factory, and its main indicators are: pH: 7.2~7.8; COD: 8000~10000mg / L; SO4 2- : 4000~6500mg / L; Na + : 8000~10000mg / L.

[0064] In the actual treatment of wastewater, the reflux ratio of wastewater after treatment is 1:1. After conditioning, the SO in wastewater 4 2- The concentration is 3g / L; COD:SO 4 2- 1.2; the reaction time (hydraulic retention time HRT) of the anaerobic biological treatment stage is controlled at 12h, the temperature is controlled at 37±0.5°C, and the effluent SO in the anaerobic biological reduction stage 4 2- The concentration is lower than 400mg / L; the reaction time (hydraulic retention time HRT) of the aerobic biological treatment stage is controlled at 1.5h, the temperature is controlled at 32±1°C, and the oxidation-reduction potential is -80mV; tetrachlorethylene and heavy stone naphtha are used as extraction agents Oil mixture, the mixing volume ratio is 7:1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com