Refining method for alkaline treatment fluid for semiconductor substrate and refining device

The technology of a substrate processing device and a refining method, which is applied in the fields of semiconductor/solid-state device manufacturing, semiconductor device, adsorbed water/sewage treatment, etc., can solve the problems of Fe pollution, economic difficulty, removal of Fe pollution, etc., and achieve excellent chemical resistance. Quality and mechanical strength, high refining effect, easy preparation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0101] Using two silicon carbide single crystal (6H) wafers with a diameter of 75 mm, the atomic force microscope (AFM) images of the mirror surfaces of these wafers were obtained in advance, and the mirror surfaces were arranged to face each other. As in the case of the previous Fe adsorption purification experiment, the formation of The adsorption sheet laminate of Example 1 with slits at a gap of 0.5 mm.

[0102] To the adsorption plate laminate of Example 1, radioactivity was added to the above-mentioned 5wt%-choline aqueous solution 59 Radioactivity from Fe 59 For the test solution with an Fe concentration of 100ppt, the Fe adsorption and purification experiment was carried out at room temperature in the same procedure as in the previous Fe adsorption and purification experiment, and the radioactivity of the test solution was obtained. 59 The residual rate of Fe.

[0103] Then, after washing the inside of the slit of the adsorption plate laminate in Example 1 in the sam...

Embodiment 2

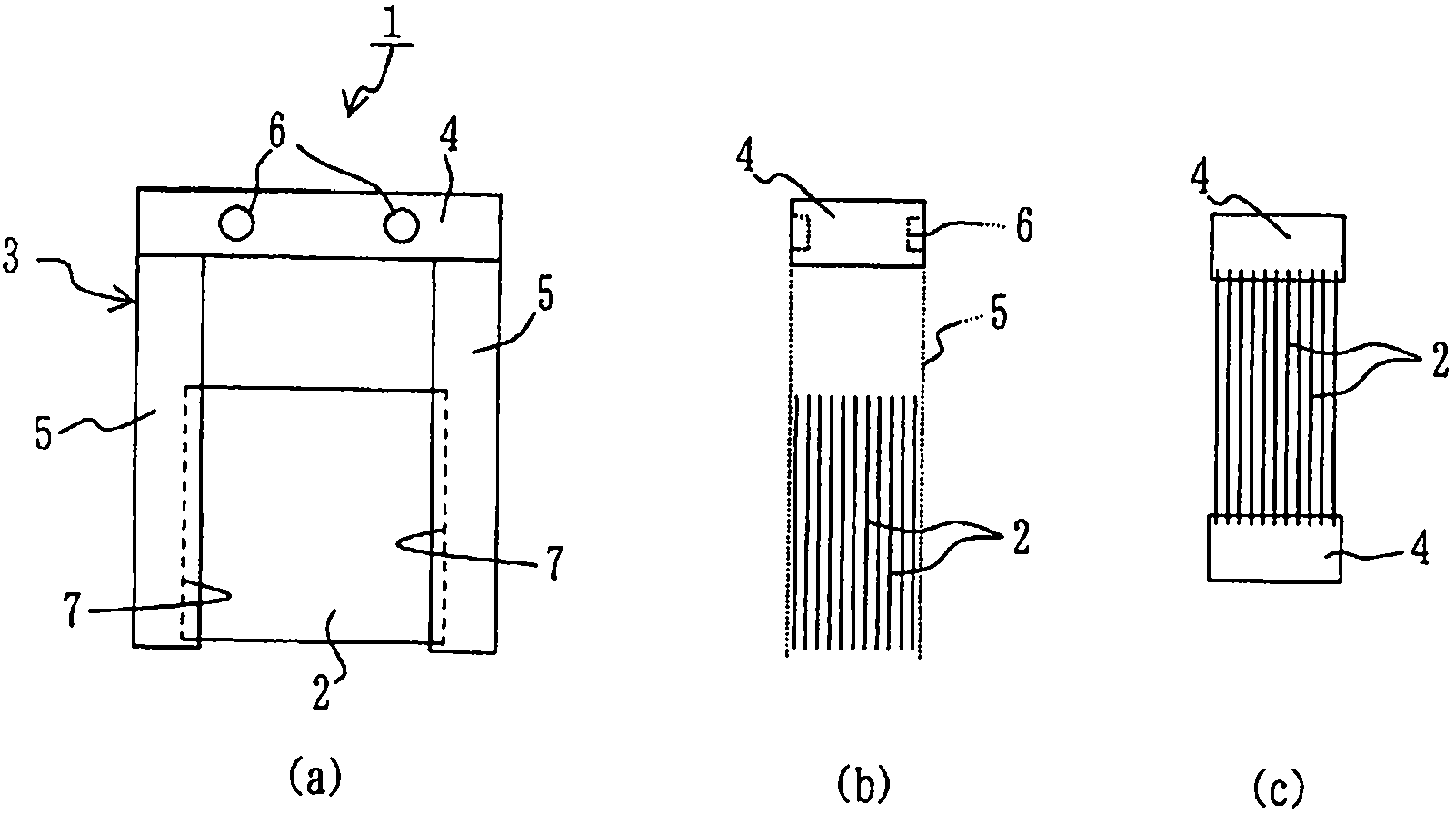

[0110] Based on the findings of the above-mentioned Example 1, as an adsorption purification device for alkaline treatment liquid, a figure 1 (a) ~ figure 1 The adsorption sheet laminate 1 shown in (c). The adsorption plate laminate 1 is cut out from a 0.6mm thick CVD polycrystalline pseudowafer (K≒0.3, with good hydrophilicity on both the surface and the back surface) by laser processing, in the form of a set of 11 pieces of 100mm×102mm in size. The adsorption plates 2 and the holding boxes 3 made of fluororesin (PTFE) hold these adsorption plates 2 at a predetermined interval (usually 0.8 to 3.0 mm, preferably 1 to 2 mm) in parallel and facing each other. . Furthermore, the holding box 3 is composed of a box top 4 having a concave portion 6 for connecting to a robot arm (not shown) for conveyance and positioning of the adsorption sheet laminate 1 and hanging from both ends of the box top 4 and facing each other. The inner surface side of the box is composed of a pair of...

Embodiment 3

[0123] In order to use high-purity silicon carbide particles (GNF-CVD manufactured by Pacific Rundom Co., Ltd.) with a particle size of 0.2 to 1.2 mm as a single crystal raw material as an adsorption refining agent, choline stock solution and nitric acid were soaked and pre-washed separately for several days Then, 60 g (apparent volume: about 30 mL) was filled into a column made of fluororesin with an inner diameter of 20 mm and a length of about 120 mm to constitute an adsorbent packed column. First, pass each 500mL of the following liquids into the tower successively: 7wt%-nitric acid aqueous solution, ultrapure water, 2wt%-hydrofluoric acid, 1wt%-hydrogen peroxide aqueous solution, ultrapure water, and then carry out the refining of the test solution experiment.

[0124] In addition, as the alkaline treatment liquid (refined liquid), use 4wt%-choline aqueous solution (choline stock solution), this liquid to be refined of 500mL is passed in the above-mentioned adsorbent pack...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com