High-performance ceramic piston ring manufacturing technology

A manufacturing technology, a technology for piston rings, applied in the direction of ion implantation plating, coating, metal material coating process, etc., can solve the problems of stress spalling, brittleness of ceramic coating, low bonding strength of substrate, etc., to achieve anti-scratch The effect of strong ability, good thermal stability and low coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Provide embodiment below in conjunction with accompanying drawing (taking molybdenum metal as example)

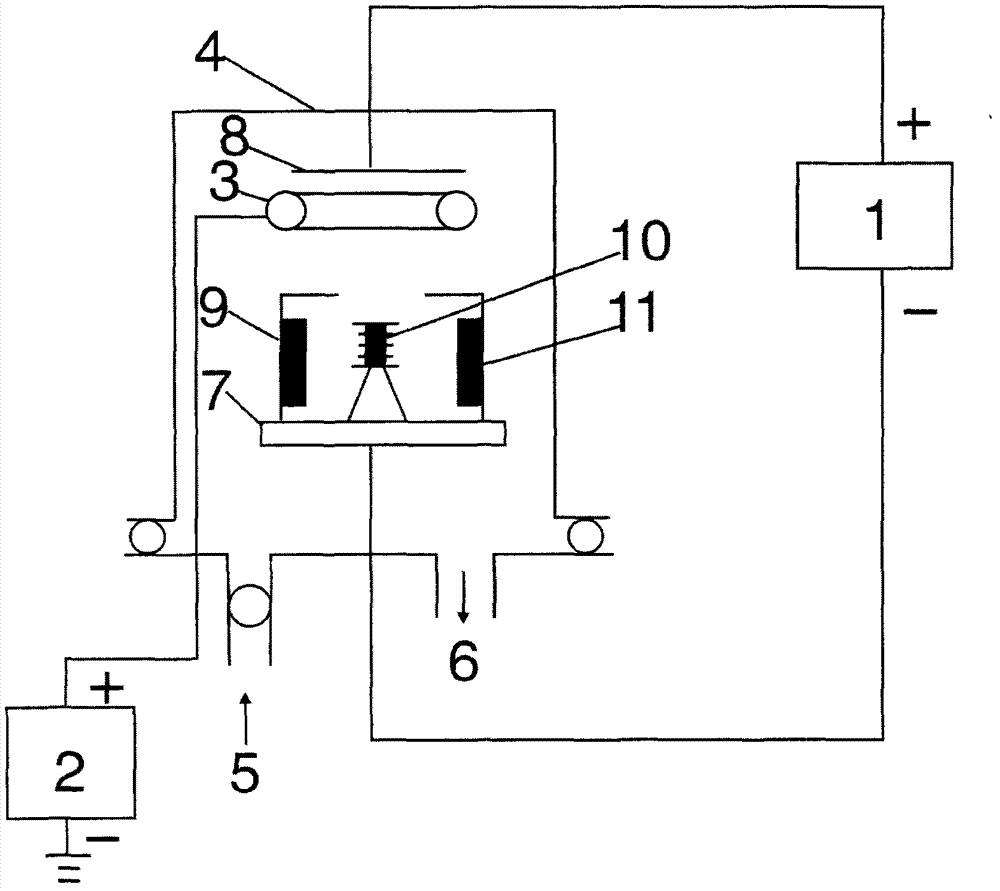

[0021] The main power supply 1 outputs 0-1000V for cathode and anode. The cathode seat 7 is connected to the negative terminal of the main power supply 1, and the anode 8 is connected to the positive terminal of the main power supply 1. The bias power supply 2 outputs 0-450V for the bias voltage ring 3 . The vacuum chamber 4 has an argon gas inlet 5 and a vacuum exhaust port 6 . The upper end of the barrel-shaped cathode 9 is open, the ultimate vacuum degree is 8.0Pa, the argon pressure is 30-40Pa; the bias voltage is 240-450v. Gradually increase the voltage of the main power supply to 500-600V, at this time the first sudden change of current occurs and glow occurs; continue to increase the voltage to 600-800V, the second sudden change of current occurs, and the normal glow discharge turns into abnormal glow Discharge produces a high temperature of 800-1000°C. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com