Electrode of solid oxide fuel battery and preparation method for solid oxide fuel battery

A solid oxide and fuel cell technology, which is applied in solid electrolyte fuel cells, battery electrodes, circuits, etc., can solve the problems of complex preparation process, increase of battery ohmic resistance, and low interface bonding strength, and achieve the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

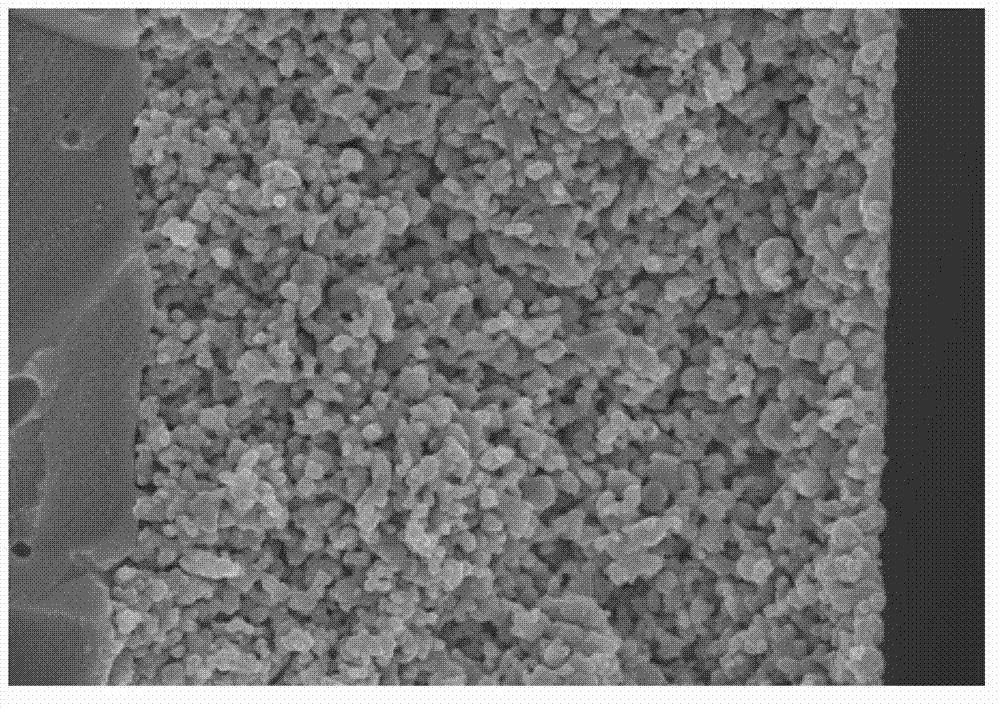

Image

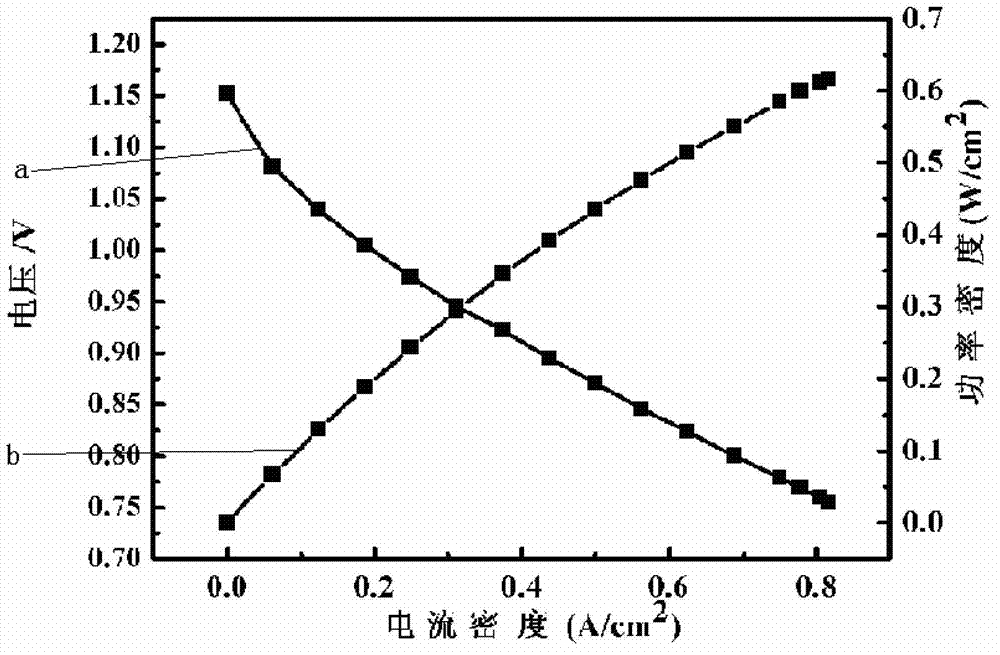

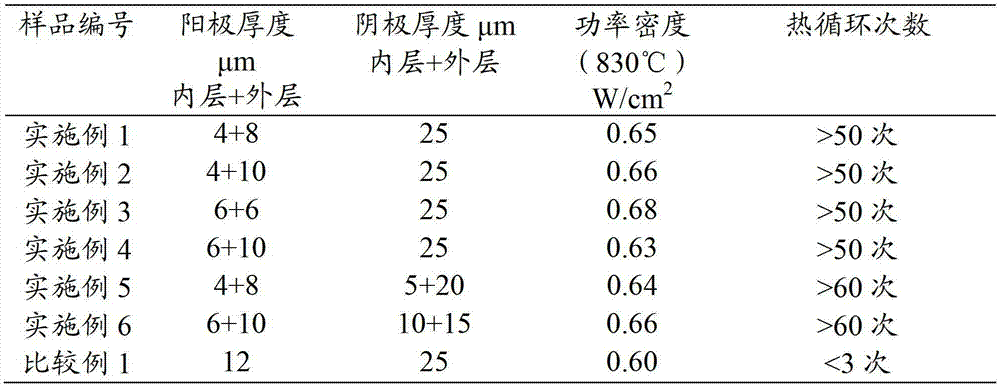

Examples

Embodiment 1

[0053] Prepare lanthanum strontium manganese (LSM) according to the method disclosed in Example 1 of patent CN102167403A, prepare scandia-doped zirconia (SSZ) according to the method disclosed in Example 5, and prepare gadolinia-doped cerium oxide according to the method disclosed in Example 6 ( GDC), nickel oxide (NiO) was prepared according to the method disclosed in Example 1 of patent CN101989664A.

[0054] Mix 60g of gadolinia-doped cerium oxide (GDC) and 40g of nickel oxide prepared above evenly, add 12g of terpineol, ball mill for 18 hours, add 4g of ethyl cellulose, and ball mill for 6 hours to prepare an anode inner layer slurry Material; 40g GDC and 60g NiO prepared above were mixed evenly, 12g terpineol was added, 4g ethyl cellulose was added after ball milling for 18 hours, and ball milling was done for 6 hours to prepare the anode outer layer slurry; the 50g lanthanum strontium prepared above Manganese and 50 g of scandia-doped zirconia (SSZ) were mixed uniformly,...

Embodiment 2

[0058] Prepare lanthanum strontium manganese (LSM) according to the method disclosed in Example 1 of patent CN102167403A, prepare scandia-doped zirconia (SSZ) according to the method disclosed in Example 5, and prepare gadolinia-doped cerium oxide according to the method disclosed in Example 6 ( GDC), nickel oxide (NiO) was prepared according to the method disclosed in Example 1 of patent CN101989664A.

[0059] Mix 70g of GDC and 30g of NiO prepared above evenly, add 12g of terpineol, ball mill for 18 hours, add 4g of ethyl cellulose, and ball mill for 6 hours to prepare an anode inner layer slurry; mix 30g of GDC and 70g of NiO prepared above Evenly, add 12g terpineol, add 4g ethyl cellulose after ball milling for 18 hours, and ball mill for 6 hours to prepare the anode outer layer slurry; mix 50g lanthanum strontium manganese and 50g scandium oxide doped zirconia prepared above evenly, Add 12g of terpineol, ball mill for 18 hours, add 4g of ethyl cellulose, and ball mill for...

Embodiment 3

[0063] Prepare lanthanum strontium manganese (LSM) according to the method disclosed in Example 1 of patent CN102167403A, prepare scandia-doped zirconia (SSZ) according to the method disclosed in Example 5, and prepare gadolinia-doped cerium oxide according to the method disclosed in Example 6 ( GDC), nickel oxide (NiO) was prepared according to the method disclosed in Example 1 of patent CN101989664A.

[0064] Mix 55g of SSZ and 45g of NiO prepared above evenly, add 12g of terpineol, ball mill for 18 hours, add 4g of ethyl cellulose, and ball mill for 6 hours to prepare an anode inner layer slurry; mix 40g of GDC and 60g of NiO prepared above Evenly, add 12g terpineol, add 4g ethyl cellulose after ball milling for 18 hours, and ball mill for 6 hours to prepare the anode outer layer slurry; mix 50g lanthanum strontium manganese and 50g scandium oxide doped zirconia prepared above evenly, Add 12g of terpineol, ball mill for 18 hours, add 4g of ethyl cellulose, and ball mill for 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com