Heterogenous catalyst, and method for coproducing 1,4-butanediol, gamma-butyrolactone and tetrahydrofuran

A heterogeneous catalyst, tetrahydrofuran technology, applied in 1 field, can solve the problems of increased production cost, increased energy consumption, strong corrosion of sulfuric acid, etc., and achieve the effects of simplifying the production process, avoiding loss, and simplifying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

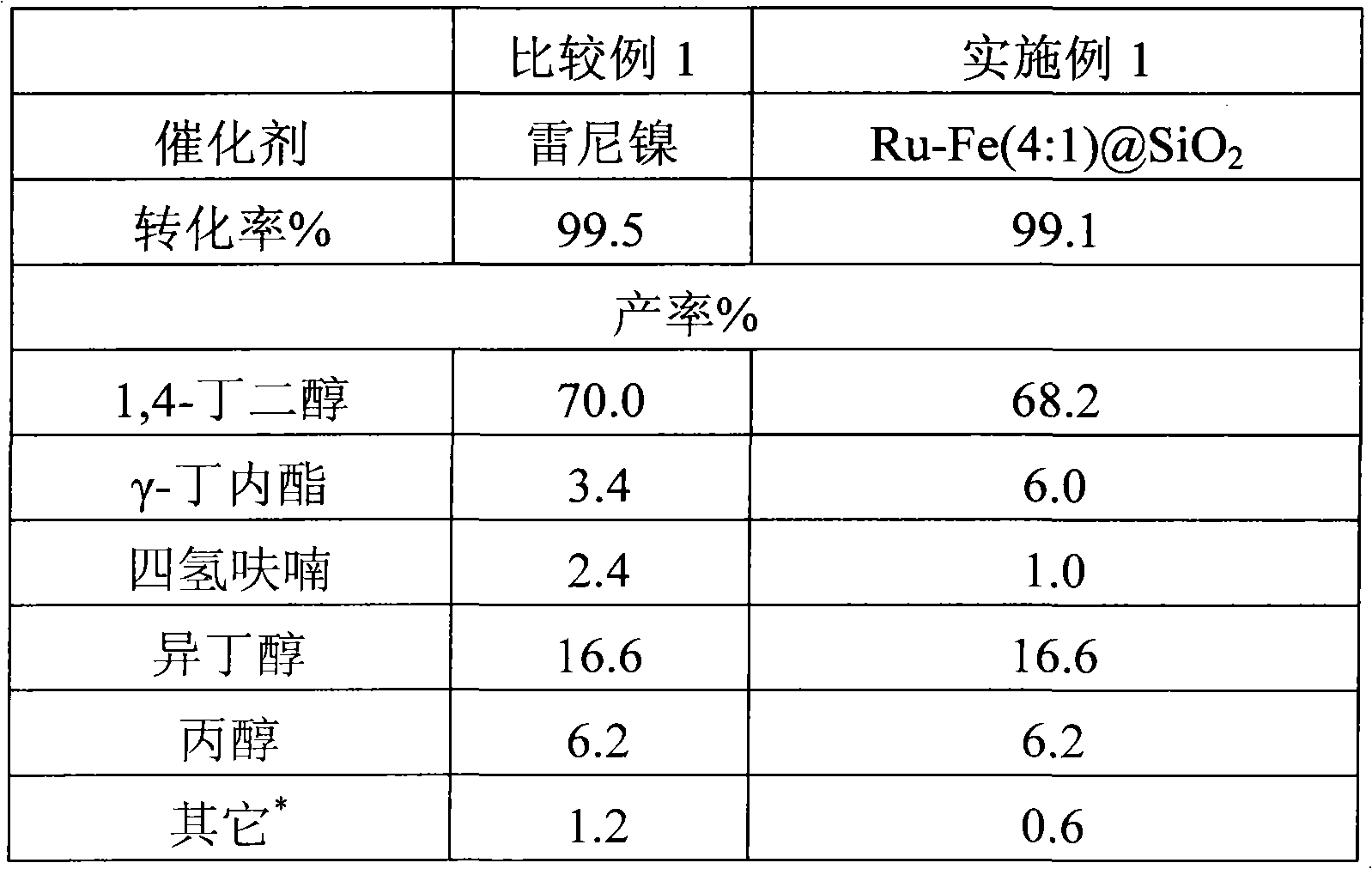

Examples

Embodiment 1

[0022] (1) Catalyst preparation

[0023] Dissolve 0.236 g of ruthenium chloride and 0.078 g of ferric nitrate in 15 ml of deionized water, add 1.28 g of polymer stabilizer polyvinylpyrrolidone, and then add 0.52 ml of formaldehyde as a reducing agent, and stir evenly in an alkaline environment. It is dissolved, then washed with acetone, and the black colloidal solution is taken out and dried. After the drying is completed, mix it with 5.735ml deionized water, 1.695ml ammonia water, 33.215ml ethanol until they are mutually soluble, then add 2.675g template tetraethyloxysiloxane (TEOS), stir for 24 hours, take out the black colloid Solution and dry. Then calcined in an air atmosphere at 400°C for 3 hours, and then calcined in an argon and hydrogen mixed gas atmosphere for 3 hours to 5 hours, and the required inert carrier is silica and the weight ratio of Ru / Fe is 4:1 catalyst. The catalyst was nitrated with nitric acid, and the weight ratio of the metal content of the catalyst ...

Embodiment 2

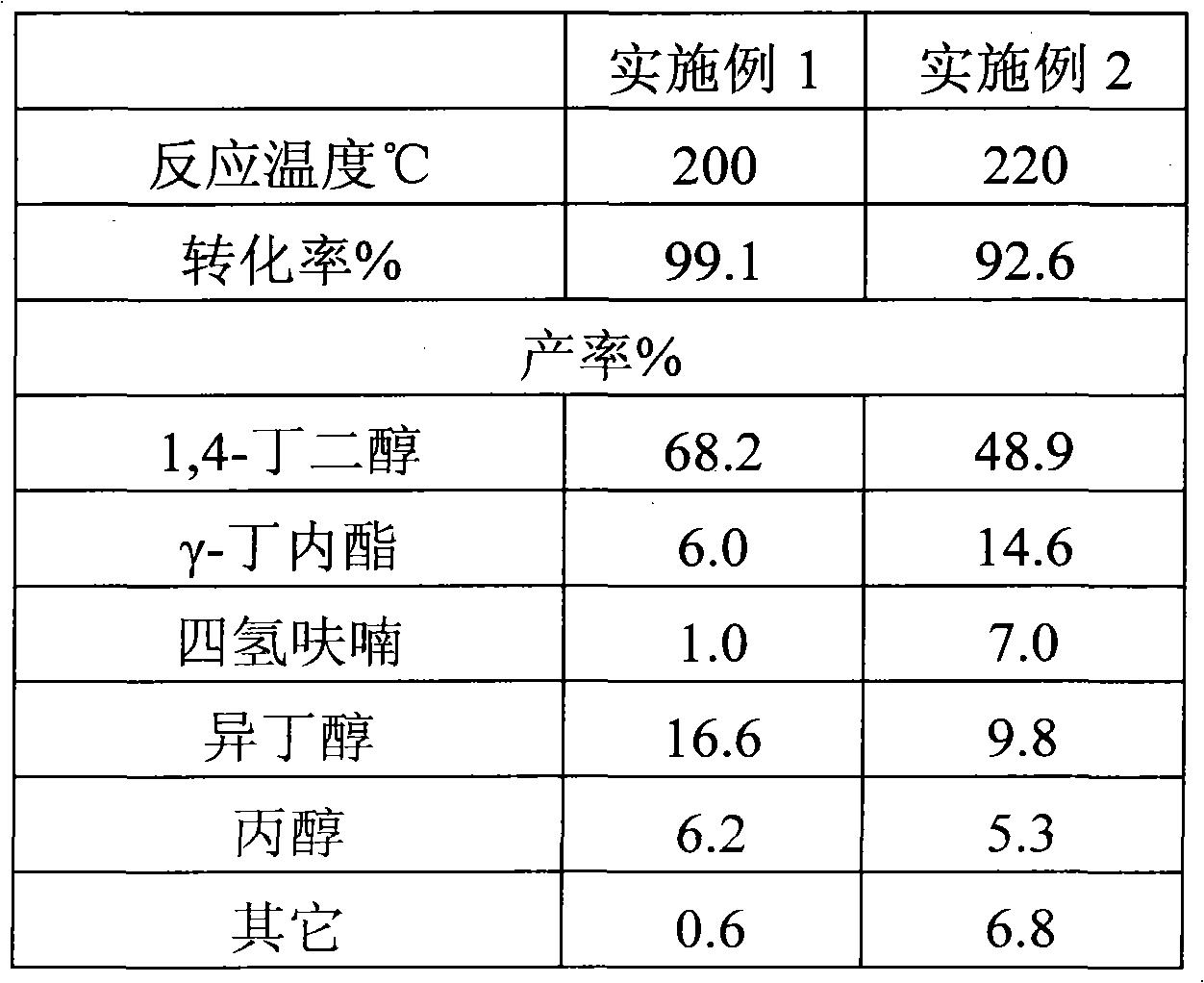

[0033] The catalyst preparation of Example 1 was repeated. The catalyst of Example 1 was used for the hydrogenation reaction test, and the reaction temperature was adjusted to 220°C. According to the experimental results in Table 2, as the reaction temperature increases, the yields of γ-butyrolactone and tetrahydrofuran increase substantially.

[0034] Table II

[0035]

Embodiment 3

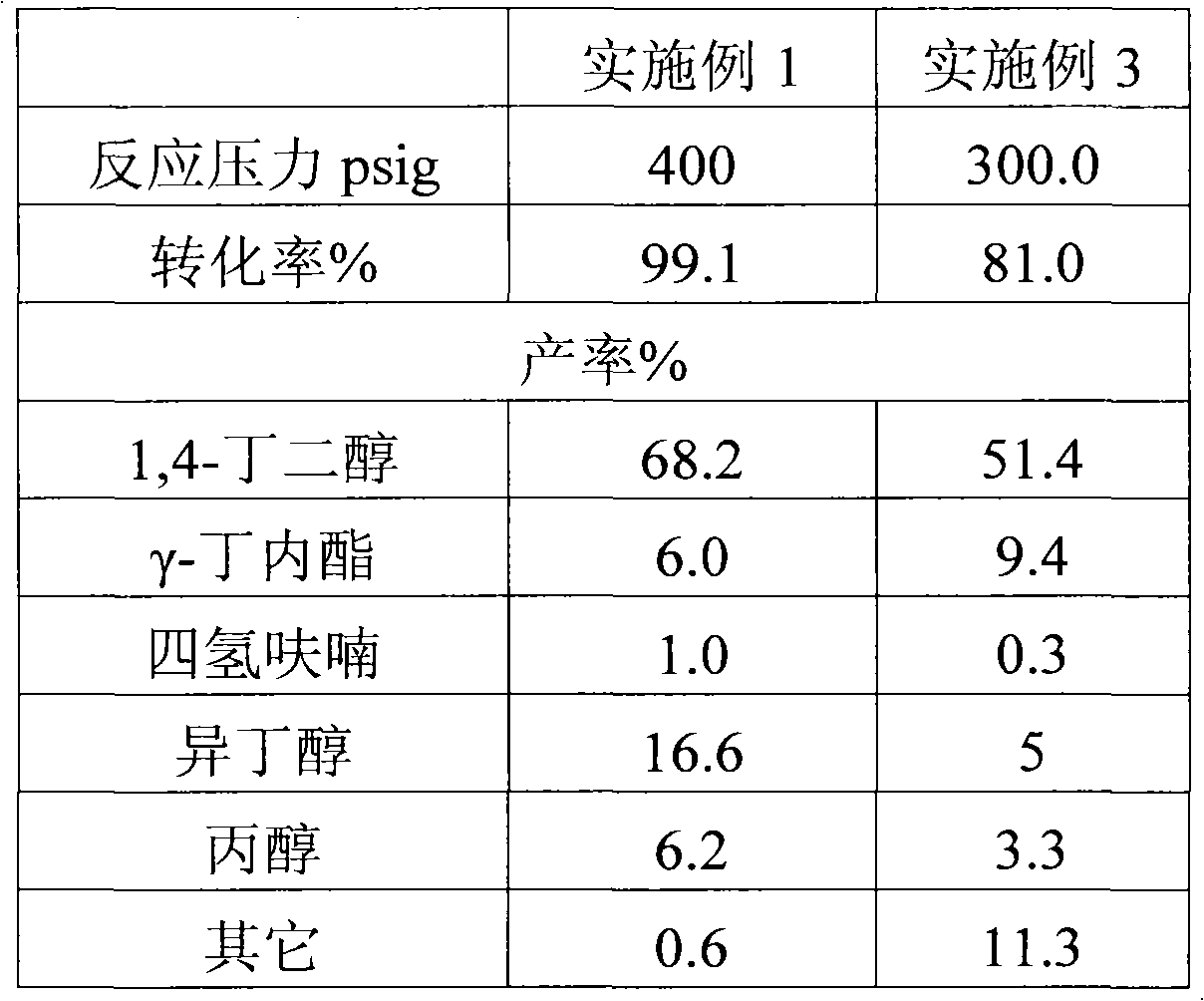

[0037] The catalyst preparation of Example 1 was repeated. The catalyst of Example 1 was used for hydrogenation reaction test. Adjust the reaction pressure to 300 psig. It can be seen from the experimental results in Table 3 that reducing the reaction pressure is beneficial to increase the yield of γ-butyrolactone

[0038] Table Three

[0039]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com