Process and device for synthesizing peroxyacetic acid

A technology of peracetic acid and synthesis process, applied in the field of chemical engineering, can solve the problems of easy explosion, low production efficiency and high reaction temperature, and achieve the effects of avoiding production accidents, eliminating potential safety hazards, and avoiding the danger of strong stimulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

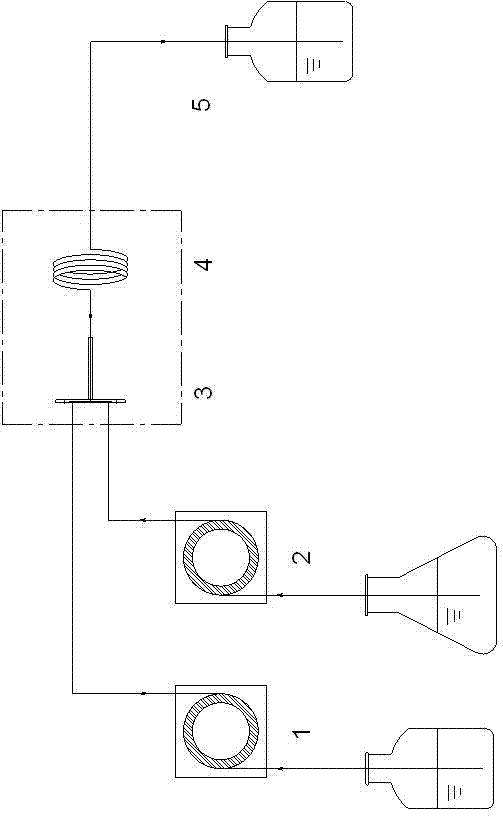

Image

Examples

Embodiment 1

[0030] Mix 50 mL acetic anhydride with 50 mL hydrogen peroxide (H 2 o 2 Solution) 30 wt%, using a medical syringe to push the T-type mixer respectively, the mixed reaction liquid enters a stainless steel pipe (microchannel reactor) with an inner diameter of 1.0 mm and a length of 2.0 m to continue the reaction, and heat is transferred to the microchannel reactor through the wall of the stainless steel pipe. Around 15 oC in the water bath, there is no significant temperature rise in the water bath. The reaction product was collected at the end of the microchannel reactor, and the peracetic acid content was determined to reach 15 wt% by iodometric method.

Embodiment 2

[0032] Both constant-flow pumps delivered acetic anhydride and 60 wt% hydrogen peroxide (H 2 o 2 Solution), the two materials are intensively mixed in a T-type micro-mixer, and the mixed materials enter a section of stainless steel pipe (microchannel reactor) with an inner diameter of 1.0 mm and a length of 12 m to continue the reaction. The exothermic heat of the reaction was transferred to the surrounding water bath at 15 oC through the wall of the stainless steel pipe, and the electric stirrer stirred the water bath rapidly without significant temperature rise. The reaction product was collected at the end of the microchannel reactor, and the content of peracetic acid was determined to reach 27 wt% by iodometric method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com