A method for preparing 5-hydroxymethylfurfural

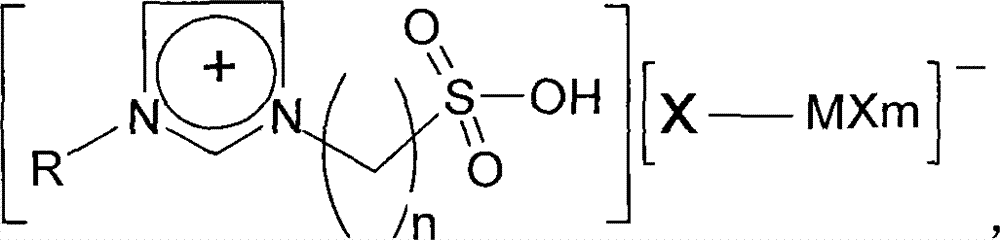

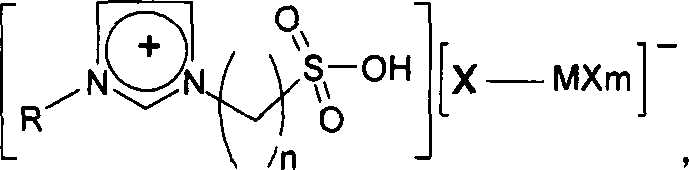

A technology of hydroxymethyl furfural and alkyl sulfonic acid, applied in the field of product 5-hydroxymethyl furfural, can solve the problems of large mass transfer and diffusion resistance, high preparation cost, low product yield, etc., and achieve unique catalytic properties, Low three-waste emissions and stable catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: 2g sucrose, 20mL dimethyl sulfoxide, 2mL water and 0.4g ionic liquid 1-(3-sulfonic acid)-propyl-3-methylimidazolium chlorochromate (acidified inner salt and chlorinated Chromium molar ratio 1:2), was added into the autoclave, heated and stirred, and reacted at 180°C for 30min. The mass fraction of 5-hydroxymethylfurfural in the obtained product was measured by an ultraviolet spectrophotometer, and the yield of HMF was calculated to be 84.7%.

Embodiment 2

[0020] Embodiment 2: 2g glucose, 15mL n-butanol, 1mL water and 0.7g ionic liquid 1-(3-sulfonic acid)-butyl-3-ethylimidazolium ferric chloride (acidified internal salt and ferric chloride mole Ratio 1:2), added into the autoclave, heated and stirred, and reacted at 200°C for 15min. The mass fraction of 5-hydroxymethylfurfural in the obtained product was measured by a spectrophotometer, and the yield of HMF was calculated to be 48.5%.

Embodiment 3

[0022] Embodiment 3: 2g sucrose, 10mL dimethyl sulfoxide, 2mL water and 0.2g ionic liquid 1-(3-sulfonic acid)-propyl-3-propylimidazole chloride zincate (acidified inner salt and chloride Zinc molar ratio 1:2), added into the autoclave, heated and stirred, and reacted at 160°C for 60min. The mass fraction of 5-hydroxymethylfurfural in the obtained product was measured by an ultraviolet spectrophotometer, and the yield of HMF was calculated to be 65.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com