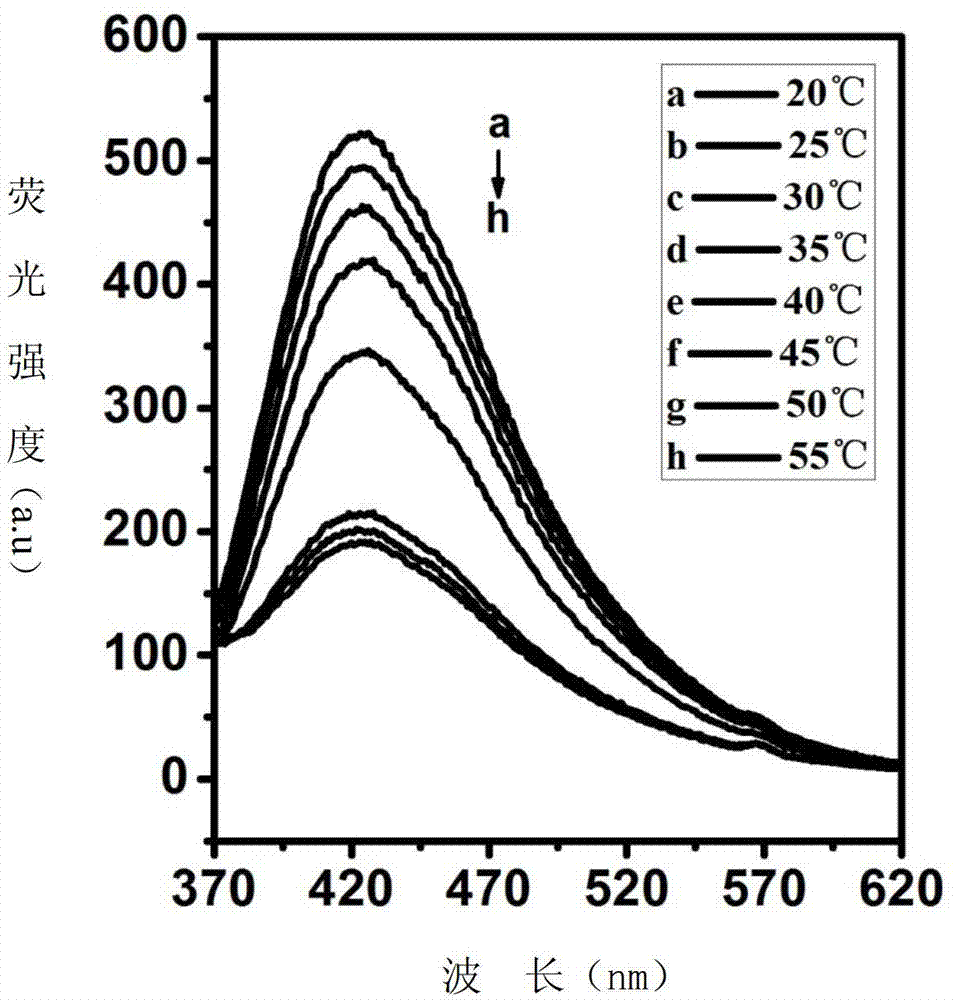

Thermo-sensitive fluorescent carbon nano composite material and preparation method thereof

A composite material, carbon nanotechnology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of limited application, environmental and human health threats, semiconductor quantum dots containing toxic metal ions, etc., to achieve a wide range of applications, coating Good sex, non-toxic effect in the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of carbon quantum dot solution:

[0028] Take 1g of egg white and raise the temperature to 250°C at a rate of 10°C / min under a nitrogen atmosphere, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain a black powder. Dissolve 0.1 g of the black powder in 10 g of deionized water, stir magnetically for 30 min, and then centrifuge at 10,000 rpm for 20 min. Take the centrifuged supernatant and filter it three times with a 200 nm ultrafiltration membrane. The carbon quantum dot solution with a concentration of 1 wt % is set aside.

[0029] 2. Preparation of poly N-isopropylacrylamide (PNIPAM) solution:

[0030] Dissolve 1.5g of PNIPAM monomer and 0.0225g of MBA in 150ml of deionized water, then blow in nitrogen gas, and stir at room temperature for 30min. Will K 2 S 2 o 8 solution (0.068g K 2 S 2 o 8 dissolved in 30ml deionized water) was added to the above solution, and the temperature was raised to 70° C. under a nitrogen...

Embodiment 2

[0038] 1. Preparation of carbon quantum dot solution:

[0039]Take 1g of egg yolk and heat it up to 250°C at a heating rate of 10°C / min under a nitrogen atmosphere, keep it warm for 2 hours, and cool it down to room temperature naturally to obtain a black powder. Dissolve 0.1 g of the black powder in 10 g of absolute ethanol, centrifuge at 10,000 rpm for 20 min after magnetic stirring for 30 min, take the centrifuged supernatant and filter it three times with a 200 nm ultrafiltration membrane, and use a carbon quantum dot solution with a concentration of 1 wt % for future use.

[0040] 2. The preparation method of poly-N-isopropylacrylamide (PNIPAM) solution is the same as in Example 1.

[0041] 3. Preparation of temperature-sensitive fluorescent carbon nanocomposites:

[0042] Dissolve 0.89g of acrylamide (AAm) in 30mL of deionized water, add 138mg of N,N-methylenebisacrylamide (MBA), mix well and add 3mL of carbon quantum dot solution with a concentration of 1wt% and a conc...

Embodiment 3

[0044] 1, the preparation method of carbon quantum dot solution is the same as embodiment 1:

[0045] 2. The preparation method of poly-N-isopropylacrylamide (PNIPAM) solution is the same as in Example 1.

[0046] 3. Preparation of temperature-sensitive fluorescent carbon nanocomposites:

[0047] Dissolve 0.94g of acrylamide (AAm) in 30mL of deionized water, add 138mg of N,N-methylenebisacrylamide (MBA), mix well and add 5mL of carbon quantum dot solution with a concentration of 1wt% and a concentration of 0.98 Add 3mL of wt% polyisopropylacrylamide solution, then dropwise add 13mg of tetraethylethylenediamine (TEMED), after it is completely dissolved, finally add 4mL of 28mmol / L potassium thiosulfate solution, and let it stand at room temperature After 6 hours, the temperature-sensitive fluorescent carbon nanocomposite material can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com