Electrolytic reaction tank and integrated preparing and casting device for iron and aluminum compound flocculant

An electrolytic reaction and flow control device technology, applied in the field of water treatment, can solve the problems of difficulty in accurately controlling the concentration of the medicine and the dosage of the medicine, and it is difficult to achieve the effect of the medicine treatment, and the treatment effect is difficult to achieve expectations. Small area, low management cost and small workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

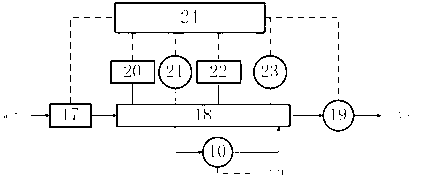

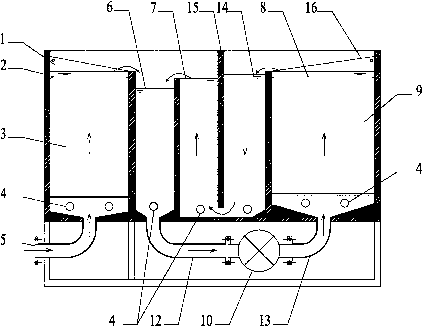

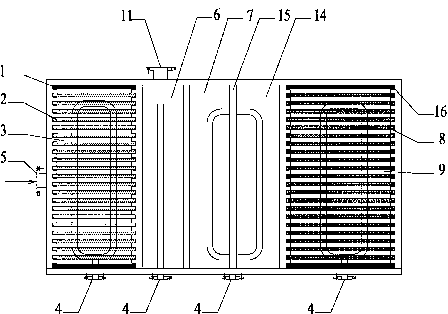

[0039] Such as figure 1 As shown, an integrated device for the preparation and dosing of an iron-aluminum composite flocculant includes a flow control device 17 connected in sequence, the above-mentioned electrolytic reaction tank 18 and a metering pump 19, and the electrolytic reaction tank 18 is connected with the aluminum electrolytic reaction tank 18 respectively. Power supply 20, blower device 21, composite electrolysis power supply 22 and liquid level gauge 23 are connected, and aluminum electrolysis power supply 20 is connected on the graphite pole plate a1 of aluminum electrolysis reaction zone 3, and composite electrolysis power supply 22 is connected in composite electrolysis reaction zone 9 On the graphite plate b16, the liquid level gauge 23 is set in the buffer zone 6 of the electrolytic reaction tank 18, the metering pump 19 is connected with the medicine outlet 11, and the blower device 21 is connected with the aeration pipe 4.

[0040] The flow control device ...

Embodiment 2

[0046] The present invention is used in the flocculation effect research of the biochemical pool of a sewage treatment plant, and the sewage treatment plant adopts A 2 / O process, collect the effluent from the biochemical section, and add PAM (polyacrylamide) with a mass concentration of 1% and PAFS (polymerized aluminum ferric sulfate) with a mass concentration of 10% according to the ratio of 0.1% (medicine dosage) And the medicament (active ingredient (Fe 2 o 3 and Al 2 o 3 The mass concentration is about 2%, and the active ingredients of iron and aluminum (respectively expressed as Fe 2 o 3 and Al 2 o 3 Count) Fe 2 o 3 with Al 2 o 3 The mass ratio is 4:1), and the comparative study of the flocculation effect is carried out;

[0047] When using the device of the present invention to prepare the flocculant, the flow rate of the water inflow is controlled to be 1m 3 / h, control the reflux ratio to 5:1, and control the constant current output of the aluminum electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com