Preparation of double-long-chain non-ionic oil-removing surfactant and applications

A surfactant, non-ionic technology, applied in the field of colloid and interfacial chemistry, can solve problems such as the inability to meet the lipophilicity of surfactants, achieve good chemical stability, excellent interfacial tension, and reduce the effect of interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

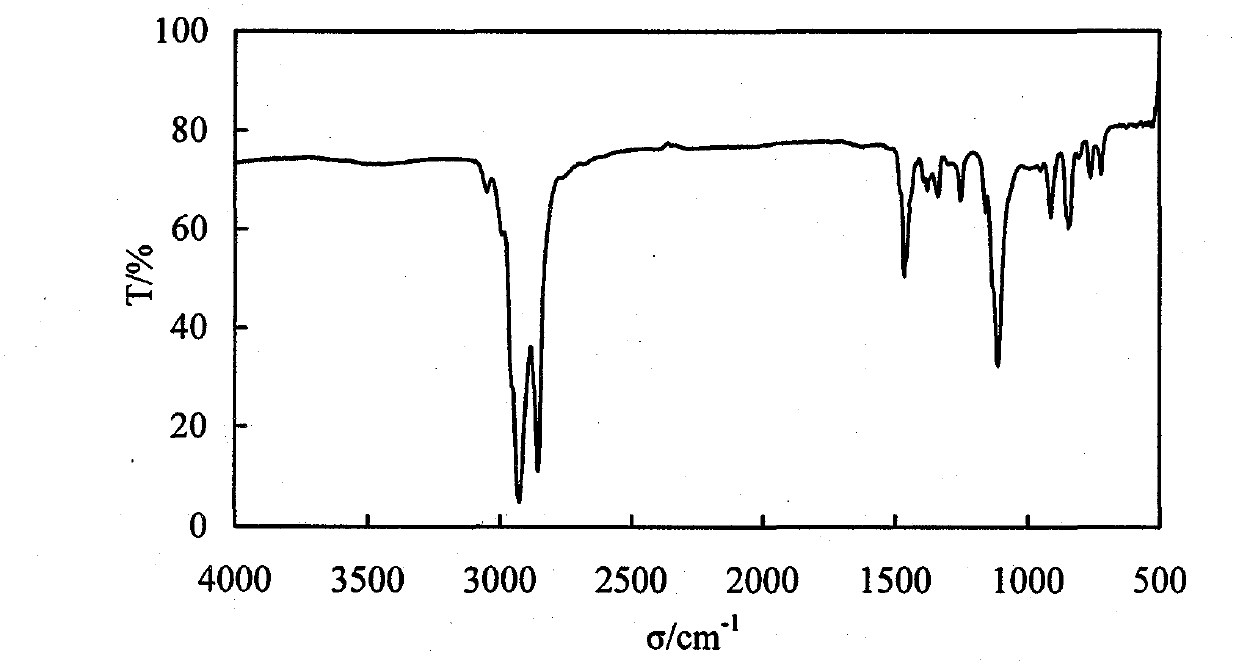

[0024] Preparation of Didodecyl Glyceryl Ether

[0025] Add 95g (0.51mol) dodecyl alcohol, 40g (0.71mol) KOH, 3.29g (0.01mol) phase transfer catalyst and 400mL n-hexane into a 1000mL four-necked flask, stir vigorously, then slowly 47 g (0.51 mol) of epichlorohydrin was added dropwise. After the dropwise addition, the temperature was raised to 40-60° C. for 6 hours. Stand to separate layers, filter under reduced pressure, discard KOH and other solids, distill the obtained light yellow solution under reduced pressure, collect fractions at 165-172°C / 3kPa, and obtain the intermediate dodecyl glycidyl ether (C 12 GE).

[0026] Add 1.0mol of dodecanol and 8mmol of KOH into a 500mL three-necked flask, and add C dropwise while stirring. 12 GE 0.4mol. After the addition, react at 110-140°C for 12h. By measuring the C in the system 12 GE's epoxy value monitors the progress of the reaction. After the reaction, the 280~295°C / 3kPa fraction was collected by vacuum distillation to obt...

Embodiment 2

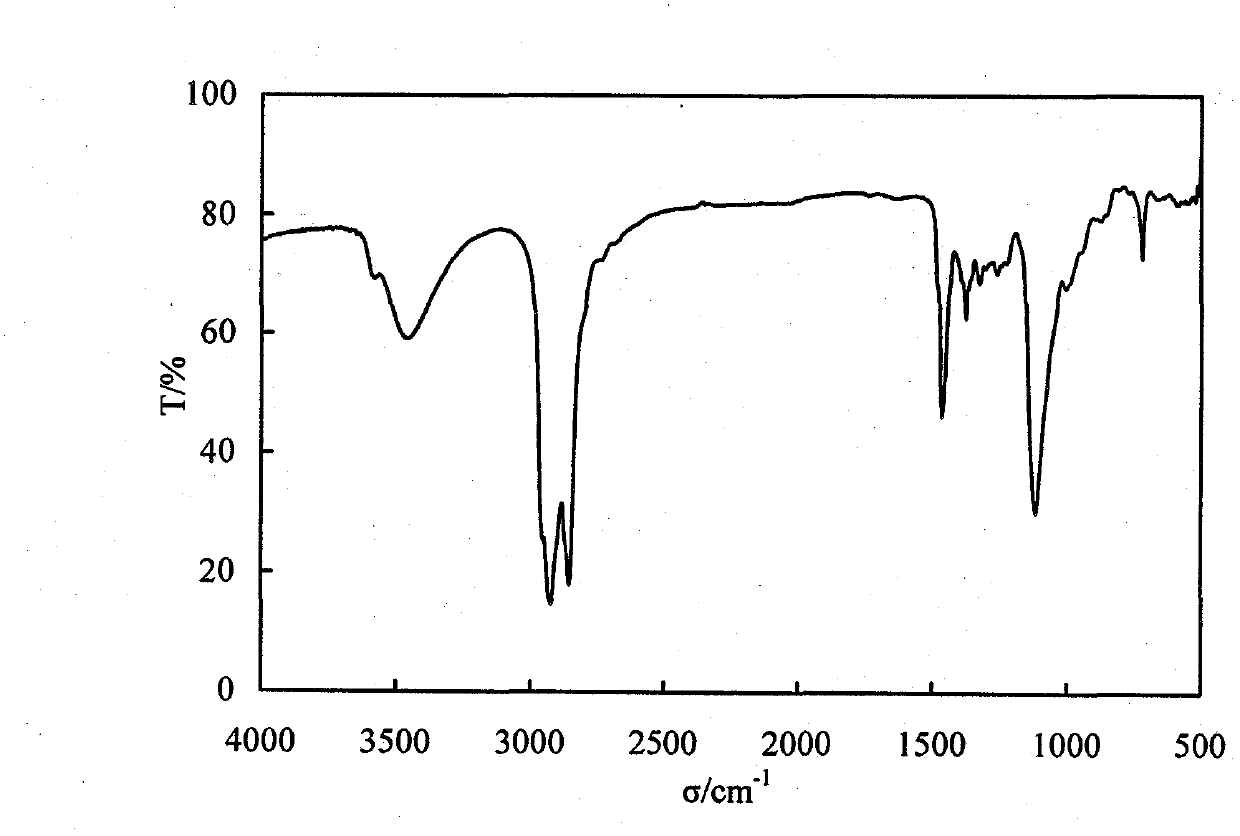

[0031] Preparation of Unsymmetrical Dilong-chain Alkyl Glyceryl Ethers

[0032] Add 95g (0.51mol) dodecyl alcohol, 40g (0.71mol) KOH, 3.29g (0.01mol) phase transfer catalyst and 400mL n-hexane into a 1000mL four-necked flask, stir vigorously, then slowly 47 g (0.51 mol) of epichlorohydrin was added dropwise. After the dropwise addition, the temperature was raised to 40-60° C. for 6 hours. Stand to separate layers, filter under reduced pressure, discard KOH and other solids, distill the obtained light yellow solution under reduced pressure, collect 165~172°C / 3kPa fraction, which is dodecyl glycidyl ether (C 12 GE).

[0033] Add 1.0mol of n-octanol and 8mmol of KOH into a 500mL three-necked flask, and add C dropwise while stirring. 12 GE 0.4mol. After the addition, react at 110-140°C for 12h. By measuring the C in the system 12 GE's epoxy value monitors the progress of the reaction. After the reaction, the 235~245°C / 3kPa fraction was collected by vacuum distillation to ob...

Embodiment 3

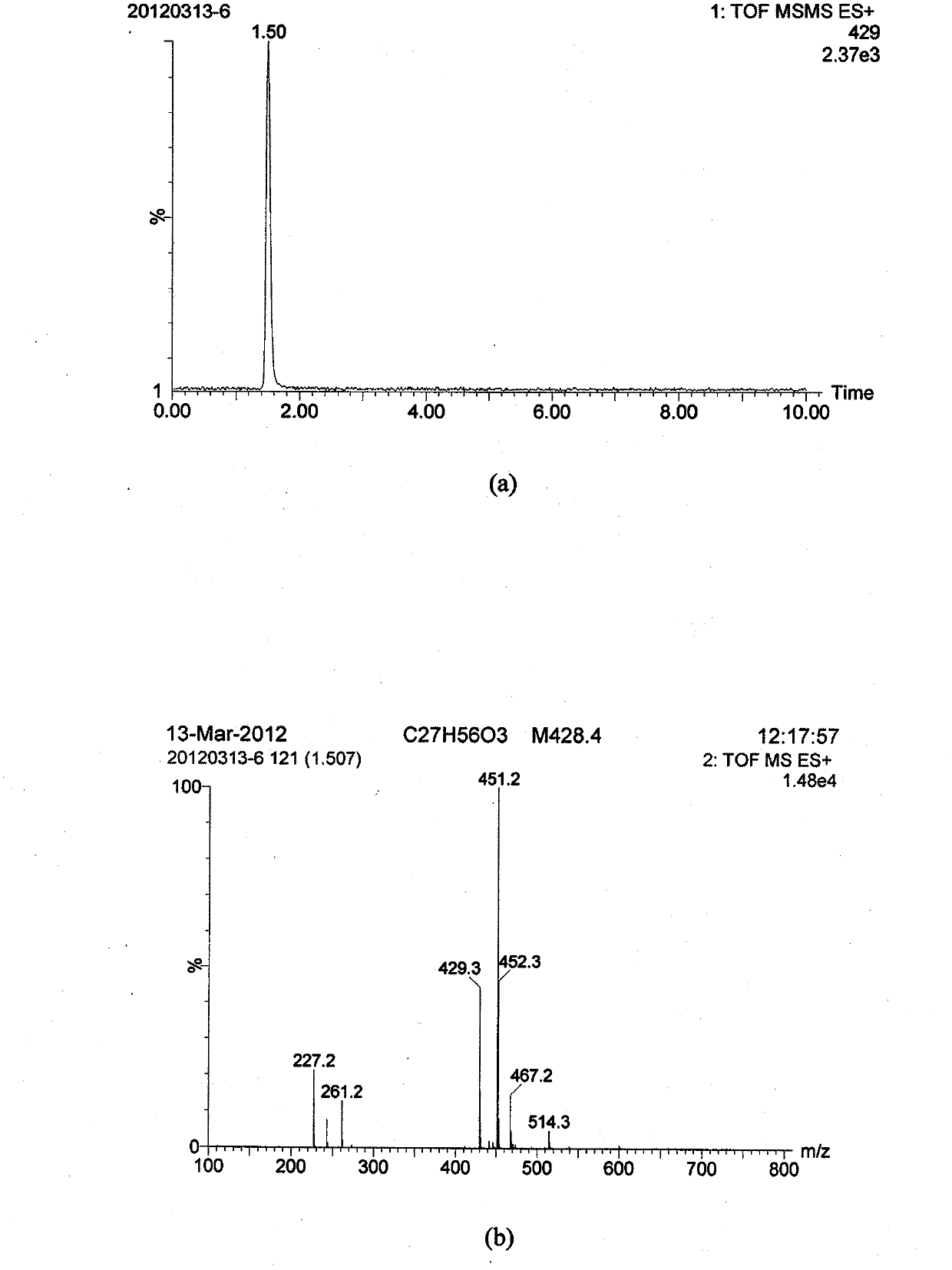

[0035] Dilauryl glyceryl ether ethoxylate (diC 12 GE-EO n ) preparation

[0036] Add 100g of 1,3-dodedecylglyceryl ether and 0.5g of KOH to a 0.5L autoclave, raise the temperature to 120°C, stir, and feed N into it 2 and vacuum. Raise the temperature to 160°C, introduce ethylene oxide until the pressure of the reactor is 0.35~0.40MPa, pass cooling water to make the system temperature react at 160~175°C, and continuously feed ethylene oxide to keep the pressure of the reactor at 0.1~ 0.35MPa. The consumption of ethylene oxide is measured with an electronic scale, and when it reaches the theoretical amount, the introduction of ethylene oxide is stopped. Continue the reaction until the pressure drops to zero, stop heating, cool down to 100°C and discharge.

[0037] Figure 4 and Figure 5 Respectively, the surface tension of didecyl glyceryl ether ethoxylate series products and didodecyl glyceryl ether ethoxylate series products varies with the concentration. It can be se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com