Washable oiliness coating adhesive and preparation method

A coating adhesive and washable technology, which is applied in textiles, papermaking, fiber treatment, etc., can solve the problems of washable oily coating adhesives that have not been disclosed, and achieve the effect of good washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

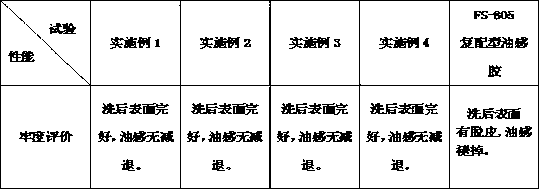

Examples

Embodiment 1

[0023] Methyl methacrylate 26, n-butyl acrylate 83, isooctyl acrylate 4, allyl methacrylate 3, vinyltrimethoxysilane 2, sodium dodecylbenzenesulfonate 0.4, fatty alcohol polyoxygen Vinyl ether XL90 is 5, refined castor oil 8, deionized water 140, put into an emulsification kettle and stir evenly to make an emulsion, and set aside;

[0024] Sodium bisulfite 0.3 plus deionized water 10 to dissolve evenly and set aside;

[0025] Ammonium persulfate 0.4 plus deionized water 40 to dissolve evenly for use;

[0026] Add 20% of the total amount of the above-mentioned emulsion into the reaction kettle, heat up to 72-75°C, add 20% of the above-mentioned aqueous solution of sodium bisulfite and 25% of the aqueous solution of ammonium persulfate to initiate the reaction, and then set the temperature at 72-75°C Add the remaining emulsion, the remaining sodium bisulfite aqueous solution, and the remaining ammonium persulfate aqueous solution dropwise, and the dropwise addition is completed...

Embodiment 2

[0028] Methyl methacrylate 25, n-butyl acrylate 76, isooctyl acrylate 3, allyl methacrylate 2, vinyltrimethoxysilane 1, sodium dodecylbenzene sulfonate 0.3, fatty alcohol polyoxygen Vinyl ether XL90 is 3, refined castor oil 8, deionized water 130, put into an emulsification kettle and stir evenly to make an emulsion, and set aside;

[0029] Sodium bisulfite 0.15 plus deionized water 10 to dissolve evenly and set aside;

[0030] Ammonium persulfate 0.25 plus deionized water 40 to dissolve evenly for use;

[0031] Add 20% of the total amount of the above-mentioned emulsion into the reaction kettle, heat up to 72-75°C, add 20% of the above-mentioned aqueous solution of sodium bisulfite and 25% of the aqueous solution of ammonium persulfate to initiate the reaction, and then set the temperature at 72-75°C Add the remaining emulsion, the remaining sodium bisulfite aqueous solution, and the remaining ammonium persulfate aqueous solution dropwise. After 2.5-2.7 hours, the dropwise a...

Embodiment 3

[0033] Methyl methacrylate 29, n-butyl acrylate 80, isooctyl acrylate 4, allyl methacrylate 2.5, vinyltrimethoxysilane 3, sodium dodecylbenzene sulfonate 0.5, fatty alcohol polyoxygen Vinyl ether XL90 is 4.5, refined castor oil is 10, and deionized water is 150, put into an emulsification kettle and stir evenly to make an emulsion, which is ready for use;

[0034] Sodium bisulfite 0.4 plus deionized water 10 to dissolve evenly and set aside;

[0035] Ammonium persulfate 0.5 plus deionized water 40 to dissolve evenly for use;

[0036] Add 20% of the total amount of the above-mentioned emulsion into the reaction kettle, heat up to 72-75°C, add 20% of the above-mentioned aqueous solution of sodium bisulfite and 25% of the aqueous solution of ammonium persulfate to initiate the reaction, and then set the temperature at 72-75°C Add the remaining emulsion, the remaining sodium bisulfite aqueous solution, and the remaining ammonium persulfate aqueous solution dropwise, and the dropw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com