Preparation of Cu2O/TNTs (TiO2 nanotubes) heterojunction nano composite material and CO2 photoreduction method

A nanocomposite material and heterojunction technology, which is applied in the field of preparation of Cu2O/TNTs heterojunction nanocomposite materials, can solve the problems of low photocatalytic efficiency and unutilized visible light, and achieve low preparation cost and good photoreduction. The ability of CO2, the effect of simple materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1) Pretreatment of titanium sheet

[0045] A titanium sheet with a size of 3 cm × 3 cm was ultrasonicated in acetone and ethanol solutions for 15 min, air-dried, and then immersed in HF:HNO 3 :H 2 O = 1:4:5 (volume ratio) mixed acid for 30 s, then diluted with water and removed the mixed acid solution, and finally cleaned with deionized water. Put the treated titanium sheet in air to dry, the surface of the treated titanium sheet is clean and bright without impurities.

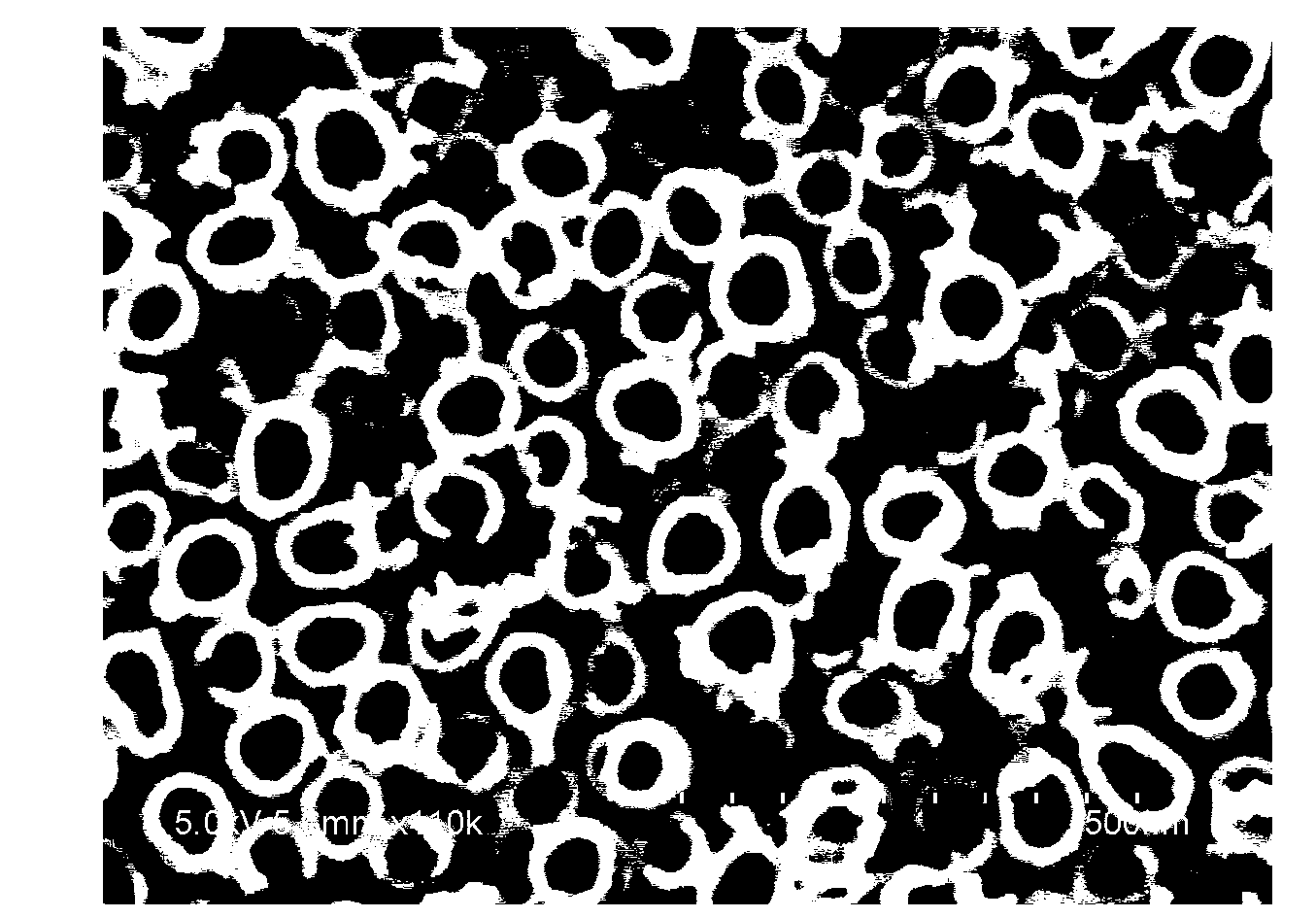

[0046] 2), using one-step anodic oxidation method to prepare TiO 2 nanotube array

[0047] Titanium sheets and graphite electrodes are respectively connected to the positive and negative poles of the DC stabilized power supply, glycerol, 1wt% NH 4 F (mass fraction) and 15vol% H 2 O (volume fraction) solution is the electrolyte, and a DC voltage of 25V is applied. After 2 h of reaction, the sample was calcined in a tube furnace at 450 °C for 3 h and then cooled to room temperature to obtain TiO 2 ...

Embodiment 2

[0053] 1), pretreatment of titanium sheet (same as embodiment 1)

[0054] 2), using one-step anodic oxidation method to prepare TiO 2 Nanotube array (same as embodiment 1)

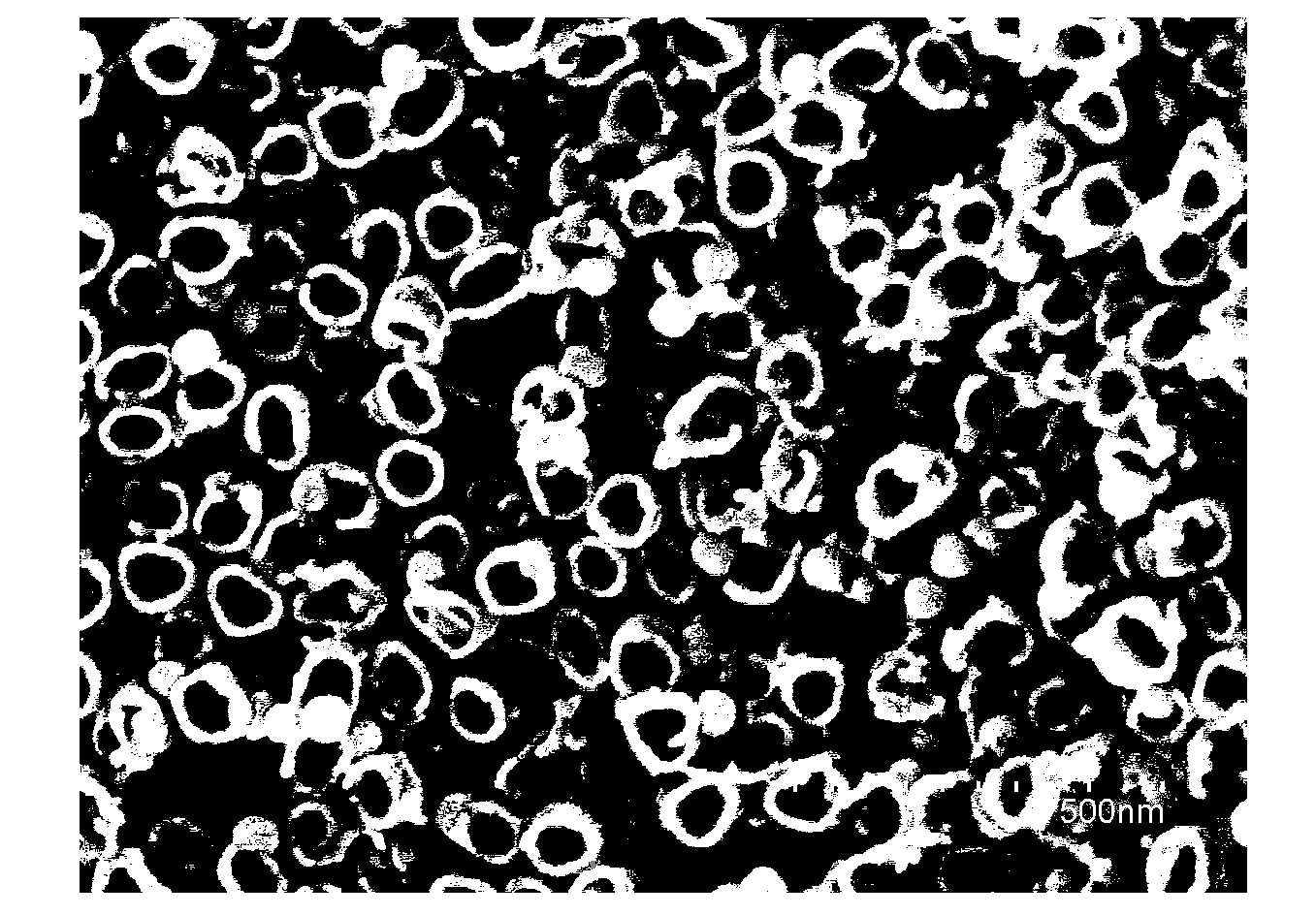

[0055] 3) Preparation of Cu by electrochemical deposition 2 O / TNTs Heterojunction Nanocomposites

[0056] at 3 mol L ?1 Dissolve 0.4 mol·L in the lactic acid solution ?1 CuSO 4 And adjust the pH to 11.0 to obtain the electrolyte. In the three-electrode system with TNTs as the working electrode, control the electrochemical deposition parameters: the temperature is 25 ℃, the deposition potential is -0.8 V, the deposited charge is 1.0 C, and Cu 2 O nanoparticles were electrodeposited into TNTs. After the reaction, wash with deionized water, dry, and anneal at 200 °C for 10 min to obtain Cu 2 O / TNTs heterojunction nanocomposites.

[0057] 4), Cu 2 Photoreduction of CO by O / TNTs Heterojunction Nanocomposite 2 gas

[0058] in CO 2 Cu at 1.0 C in 100 mL of distilled water at 50 PSI 2 The O / TNTs heter...

Embodiment 3

[0060] 1), pretreatment of titanium sheet (same as embodiment 1)

[0061] 2), using one-step anodic oxidation method to prepare TiO 2 Nanotube array (same as embodiment 1)

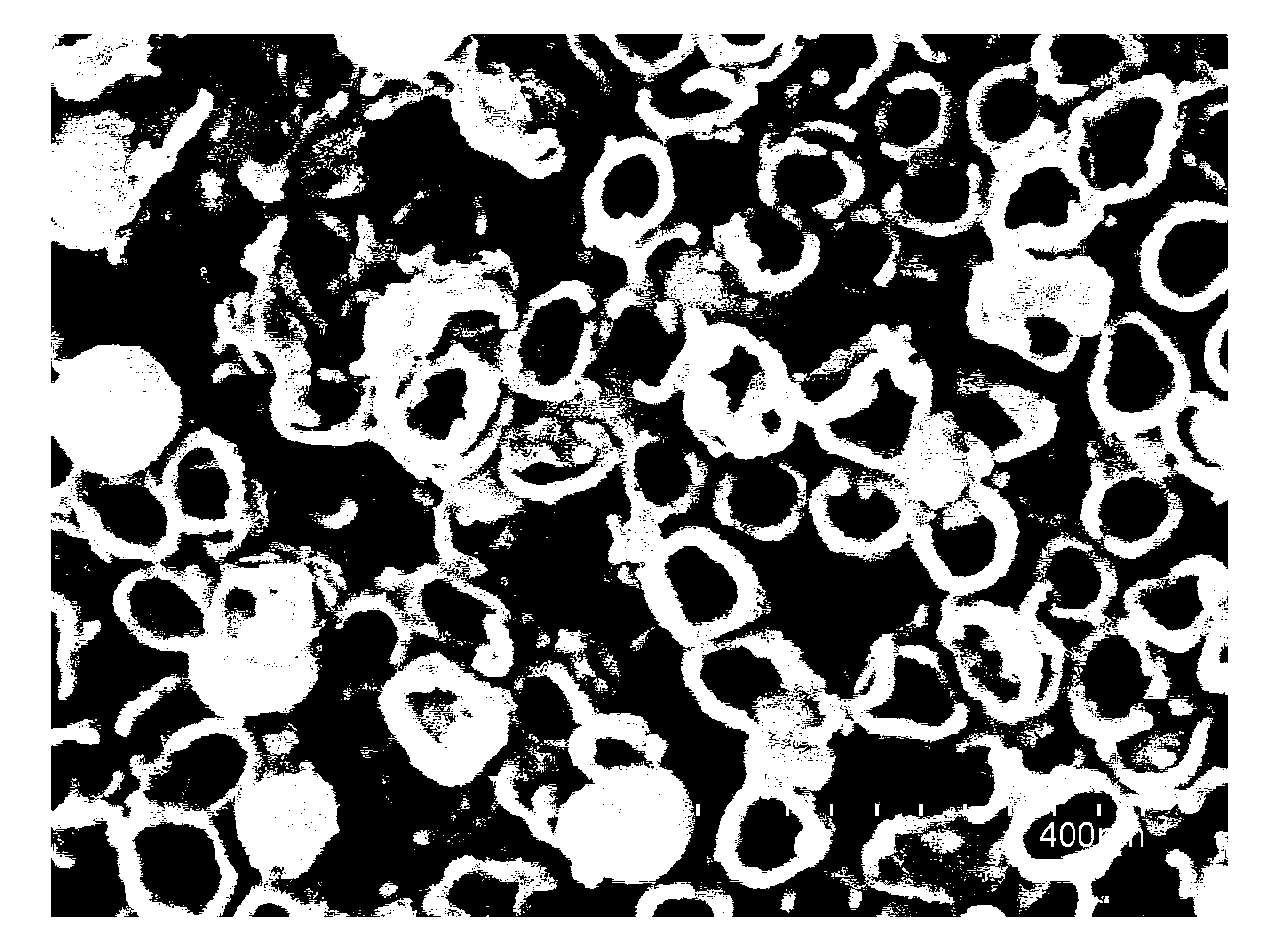

[0062] 3) Preparation of Cu by electrochemical deposition 2 O / TNTs Heterojunction Nanocomposites

[0063] at 3 mol L ?1 Dissolve 0.4 mol·L in the lactic acid solution ?1 CuSO 4 And adjust the pH to 11.0 to obtain the electrolyte. In the three-electrode system with TNTs as the working electrode, control the electrochemical deposition parameters: the temperature is 25 ℃, the deposition potential is -0.8 V, the deposited charge is 1.5 C, and the Cu 2 O nanoparticles were electrodeposited into TNTs. After the reaction, wash with deionized water, dry, and anneal at 200 °C for 10 min to obtain Cu 2 O / TNTs heterojunction nanocomposites.

[0064] 4), Cu 2 Photoreduction of CO by O / TNTs Heterojunction Nanocomposite 2 gas

[0065] in CO 2 Cu at 1.5 C in 100 mL of distilled water at 50 PSI 2 The O / TNTs h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com