High-performance concrete exposed aggregate agent as well as preparation method and application method for same

A technology of high-performance concrete and application method, applied in the field of cement concrete building materials, can solve the problems of easy evaporation of water on the surface of concrete, and achieve the effects of easy control of exposed stone depth, good curing effect, and large exposed stone time range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Huaxin P.0.42.5 Portland cement was used to prepare cement concrete with Bahe yellow sand with a particle size distribution of 4.75-15mm crushed stone and a fineness modulus of 2.3. The mix ratio is shown in Table 1.

[0031] Table 1 Mix ratio of exposed stone concrete

[0032]

[0033] In parts by mass, 70 parts of water were heated to 40°C, and then 10 parts of sodium citrate, 5 parts of phosphine butane tricarboxylic acid, 2 parts of sodium fluorosilicate, 2 parts of urea, 0.3 parts of surfactant, 0.5 parts of Parts of phthalocyanine pigments are stirred and mixed evenly in the reaction kettle and fully dissolved. The solution was allowed to stand for 2 hours and cooled to room temperature, and 0.5 part of sodium carboxymethyl cellulose was used to adjust the Engels viscosity of the solution to 50s and the pH value to be 10 to obtain component A. 50 parts of water, 30 parts of industrial water glass, 3 parts of sodium hydroxide, and 0.1 part of polyacrylamide are...

Embodiment 2

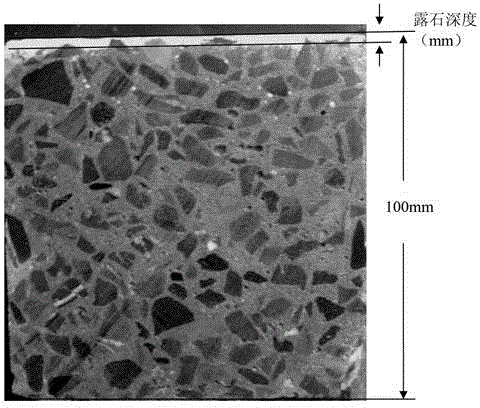

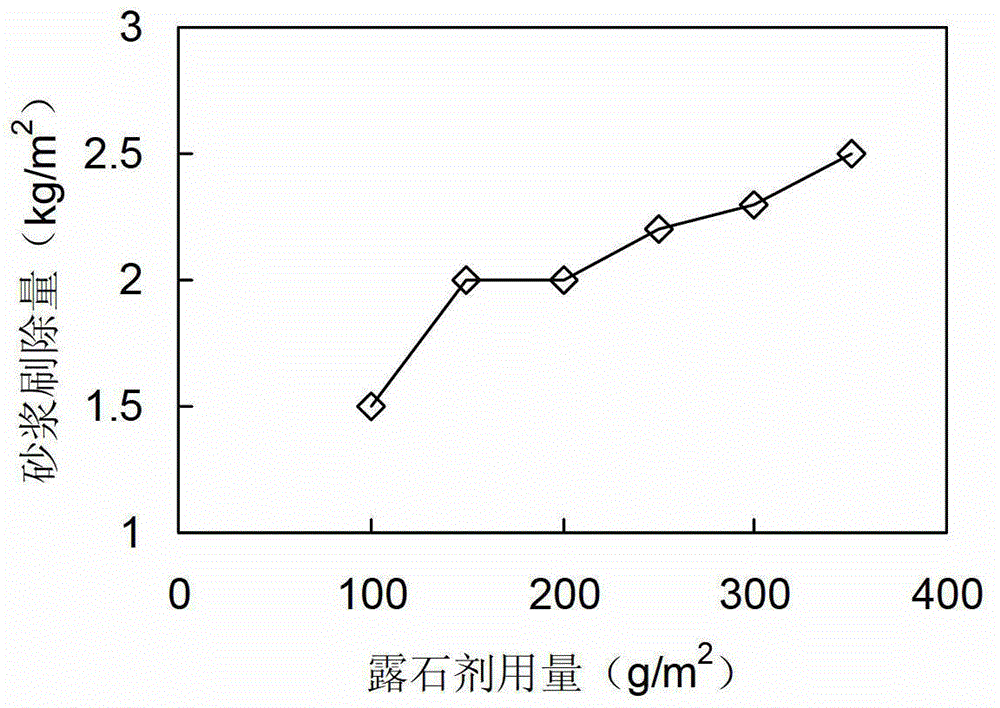

[0036] Use the mixing ratio in table 1 to prepare concrete, adopt the stone-exposing agent among the embodiment 1, after the concrete molding is plastered, be placed on the surface without obvious water residue (30-90min) and spray the stone-exposing agent A component that is diluted 6 times, and the spraying amount is respectively For: 10Og / m 2 , 15Og / m 2 , 20Og / m 2 , 250g / m 2 , 300g / m 2 , 350g / m 2 , after standing for 10min, spray the dewstone agent B component 150g / m 2 , under the condition of 20 ℃ curing, after 24 hours, use tap water to wash off the surface mortar, and measure the brushing amount of the surface mortar and the structural depth of the exposed concrete slab (according to the standard method of T0961-1995), See test results image 3 and Figure 4 .

Embodiment 3

[0038] Use the mixing ratio in table 1 to prepare concrete, adopt the exposed stone agent prepared in Example 1, after the concrete is formed and plastered, be placed on the surface without obvious water residue (30-90min), spray and dilute 6 times of the exposed stone agent A component, The spraying amount is 250g / m 2 , after standing for 10min, spray the dewstone agent B component 150g / m 2 , cured at 20°C, and the surface mortar was washed with tap water at 14 hours, 20 hours, 26 hours, 32 hours, 38 hours, 44 hours and 56 hours respectively, and the structure of exposed stone concrete was determined. Depth (according to T0961-1995 standard method) and surface mortar brushing amount, see the test results Figure 5 and Image 6 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com