Starch-liquefying modified thermosetting resin film-coated controlled release fertilizer and preparation method thereof

A starch liquefaction modification and resin coating technology, which is applied in fertilizer mixtures, fertilization devices, applications, etc., can solve problems such as difficulty in sustainable development relying on petrochemical products, high cost of controlled release fertilizers, and slow degradation of polymer residual films. , to achieve the effects of excellent nutrient release performance, suitable for large-scale industrial production, and increased reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

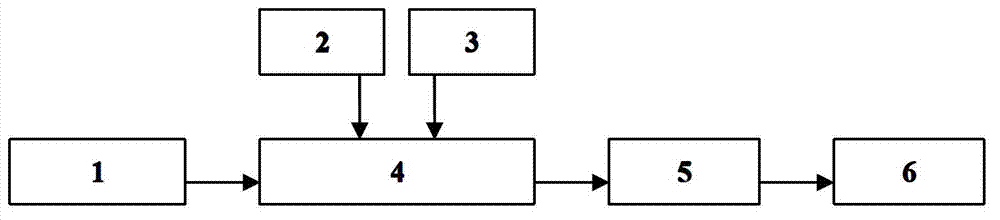

Image

Examples

Embodiment 1

[0021] Add 100g of diethylene glycol, 80g of wheat starch and 1g of concentrated sulfuric acid into a three-necked flask equipped with mechanical stirring and a condenser, and stir to make them evenly mixed. React at 140-150°C for 30 minutes, then cool to about 100°C with an ice-water bath. Put 500g of large granular urea with a diameter of 2-4mm into the drum and heat it to 50-70°C; then put 4.55g of wheat starch coating solution and 4.41g of curing agent polymethylene polyphenyl group cooled to about 100°C The polyisocyanate is quickly sprayed onto the surface of urea granules at the same time, and after 5-6 minutes, it can be directly reacted and solidified to form a film on the surface of the fertilizer. The spraying process is repeated 3 times. After the fertilizer is cooled, it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5% of the total weight of all controlled-release fertilizers, and the controlled-release ti...

Embodiment 2

[0023] Add 80g of polyethylene glycol, 20g of glycerol, 100g of cornstarch and 1g of concentrated sulfuric acid into a three-necked flask equipped with a mechanical stirrer and a condenser, and stir to make them evenly mixed. React at 140-150°C for 45 minutes, then cool to about 100°C with an ice-water bath to obtain a cornstarch coating solution. Put 500g of large granular urea with a diameter of 2-4mm into the drum and heat it to 50-70°C; then put 5.11g of corn starch coating solution and 4.02g of curing agent polymethylene polyphenyl group cooled to about 100°C The polyisocyanate is quickly sprayed onto the surface of the urea at the same time. After 5-6 minutes, it can be directly reacted and solidified to form a film on the surface of the fertilizer. The spraying process is repeated 3 times. After the fertilizer is cooled, it can be packaged and stored. The obtained controlled-release fertilizer film material accounts for about 5% of the total weight of all controlled-re...

Embodiment 3

[0025] Add 100g of ethylene carbonate, 80g of sweet potato starch and 1.5g of concentrated sulfuric acid into a three-necked flask equipped with a mechanical stirrer and a condenser, and stir to make them evenly mixed. React at 120-130° C. for 30 minutes, and then cool to about 100° C. in an ice-water bath to obtain sweet potato starch coating solution. Put 500g of large granular urea with a diameter of 2-4mm into the drum and heat it to 50-70°C; then put 5.41g of sweet potato starch coating solution and 3.22g of curing agent polymethylene polyphenyl group cooled to about 100°C The polyisocyanate is quickly sprayed onto the surface of the urea at the same time. After 5-6 minutes, it can be directly reacted and solidified to form a film on the surface of the fertilizer. The spraying process is repeated 3 times. Finally, the fertilizer is cooled to room temperature by a cooler, and then it can be packaged and stored. The obtained controlled-release fertilizer film material acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com