Method for preparing Cu doped TiN alloy layer on surface of titanium alloy

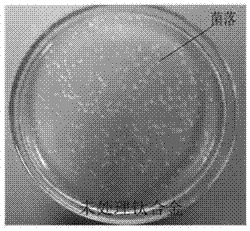

A technology for titanium alloy and alloy layer is applied in the field of preparation of alloy layer on the surface of titanium alloy, which can solve the problems of deteriorating corrosion resistance of titanium alloy surface, loss of antibacterial properties of titanium alloy, weak synergistic deformation ability, etc., so as to improve antibacterial and wear resistance. Performance, wear resistance improvement, the effect of enhancing wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] specific implementation plan

[0025] The specific implementation manners of the present invention will be further described below.

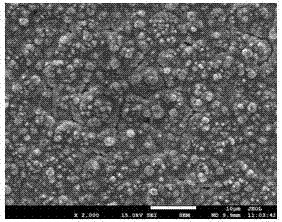

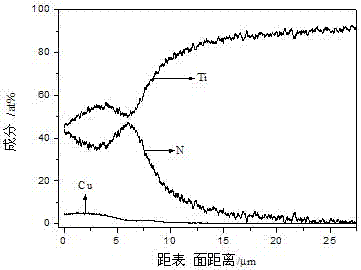

[0026] A method for preparing a Cu-doped TiN alloy layer on the surface of a titanium alloy according to the present invention is to use a titanium-copper alloy target as the source in a plasma surface alloying furnace body, and use the low-temperature plasma generated by glow discharge to bombard the source The surface of the electrode, so that the alloying elements to be infiltrated are sputtered from the surface of the source electrode, transported, deposited and adsorbed on the surface of the titanium alloy, and alloyed on the surface of the material through diffusion. After the alloying is completed, the source power is directly turned off, and the Injecting nitrogen, a Cu-doped TiN surface alloy layer will be formed on the surface of the titanium alloy after a certain period of time.

[0027] The technical scheme of the specific em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com