Method for preparing medicine-carrying wound dressing based on supercritical fluid technology

A supercritical fluid and wound dressing technology, which is applied in medical science, bandages, absorbent pads, etc., can solve the problems of excessive organic solvent content, denaturation and inactivation of protein drugs, and large amount of organic solvents, so as to achieve low solvent residue and drug The effect of less loss and mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

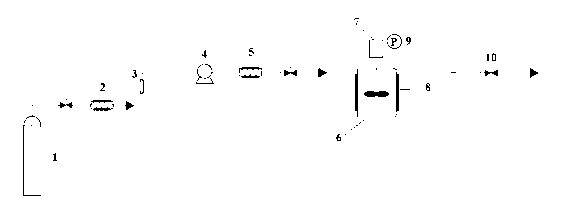

[0017] The preparation method of drug-loaded wound dressing based on supercritical fluid technology comprises the following steps:

[0018] 1) Dissolve chitosan in acetic acid aqueous solution to form a chitosan solution with a mass volume ratio of 1 to 5%, and mix the chitosan solution with a cellulose sodium sulfate aqueous solution with a mass volume ratio of 1 to 5% to form chitosan A polyelectrolyte solution with a mass ratio of 1:2 to 2:1 to cellulose sodium sulfate, take the polyelectrolyte solution, stir for 1 to 5 minutes, and freeze-dry to obtain a composite material wound dressing;

[0019] 2) Wrap the composite wound dressing in filter paper and place it in the autoclave of the supercritical fluid drug loading system. The drug is pre-filled in the autoclave, and the drug is not in direct contact with the composite wound dressing;

[0020] 3) Introduce carbon dioxide into the autoclave, and the carbon dioxide reaches a supercritical state under the conditions of a t...

Embodiment 1

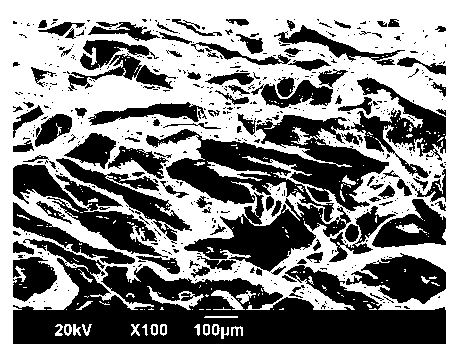

[0023] Example 1: Preparation of chitosan / cellulose sodium sulfate composite wound dressing loaded with ibuprofen

[0024] First, chitosan (122mpa.s, deacetylation degree 90%) is dissolved in acetic acid aqueous solution to form a chitosan solution with a mass volume ratio of 1%, and the chitosan solution is mixed with cellulose sodium sulfate with a mass volume ratio of 1%. (substitution degree 0.2) aqueous solution is mixed to form a polyelectrolyte solution with a mass ratio of chitosan and cellulose sodium sulfate of 1:1, and the polyelectrolyte solution is stirred with a stirrer for 1 min, and the obtained polyelectrolyte solution is freeze-dried to obtain chitosan / Cellulose Sodium Sulfate Composite Wound Dressing. The prepared composite wound dressing was wrapped in filter paper and placed in an autoclave. 2 g of ibuprofen was placed in the autoclave in advance, and the ibuprofen did not directly contact with the composite wound dressing. Use the cooling tank to coo...

Embodiment 2

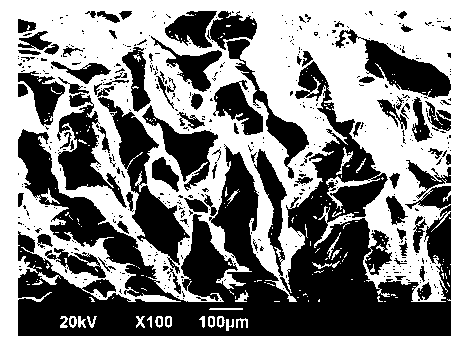

[0029] Example 2: Preparation of chitosan / cellulose sodium sulfate composite wound dressing loaded with ibuprofen

[0030] First, chitosan (186mpa.s, deacetylation degree 95%) is dissolved in acetic acid aqueous solution to form a chitosan solution with a mass volume ratio of 3%, and the chitosan solution is mixed with cellulose sodium sulfate with a mass volume ratio of 5%. (substitution degree 0.2) aqueous solution was mixed to form a polyelectrolyte solution with a mass ratio of chitosan and cellulose sodium sulfate of 1:2, and the polyelectrolyte solution was stirred with a stirrer for 5 minutes, and the obtained polyelectrolyte solution was freeze-dried to obtain chitosan / Cellulose sodium sulfate composite wound dressing. The prepared composite wound dressing was wrapped in filter paper and placed in an autoclave. 2 g of ibuprofen was placed in the autoclave in advance, and the ibuprofen did not directly contact with the composite wound dressing. Use the cooling tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com