Preparation method of modified chrome-aluminum phosphate

A chromium-aluminum phosphate modification technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as unstable dielectric properties of materials, deterioration of wave-transmitting performance of radome, shortening of radar action distance, etc., to achieve Active chemical properties, reduce moisture absorption, improve the effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A preparation method of modified chromium aluminum phosphate: add 57.98g of phosphoric acid aqueous solution with a mass percentage concentration of 65% in a 500ml three-neck flask equipped with a booster stirrer and a condensation reflux device, then add 10.0g of aluminum hydroxide, Stir at 80°C for 25 minutes, then add 4.27g of chromium oxide, stir and react to an orange transparent solution; adjust the temperature to about 140°C and add 1.39g of modifier lanthanum oxide, react for half an hour, then slowly add methanol 3.0 g, until the oxidation-reduction reaction is completed, keep it warm for 60 minutes, and synthesize a green viscous liquid rare earth chromium aluminum phosphate binder, which is to obtain a modified chromium aluminum phosphate.

[0015] Put the same amount of modified chromium aluminum phosphate and unmodified chromium aluminum phosphate in a constant temperature and humidity environment (parameters are 25°C, 80%RH), record the change of their weig...

Embodiment 2

[0019] A preparation method of modified chromium aluminum phosphate is: add 57.98 g of phosphoric acid aqueous solution with a mass percentage concentration of 65% in a 500 ml three-necked flask equipped with a booster stirrer and a condensing reflux device, and then add 10.0 g of aluminum hydroxide, Stir at 80°C for 30 minutes, then add 4.27g of chromium oxide, stir and react to an orange transparent solution; adjust the temperature to about 90°C, add 2.35g of modifier cerium oxide, react for half an hour, then slowly add methanol 3.0 g, until the oxidation-reduction reaction is completed, keep it warm for 90 minutes, and synthesize a green viscous liquid rare earth chromium aluminum phosphate binder, which is to obtain a modified chromium aluminum phosphate.

[0020] Put the same amount of modified chromium aluminum phosphate and unmodified chromium aluminum phosphate in a constant temperature and humidity environment (parameters are 25°C, 80%RH), record the change of their w...

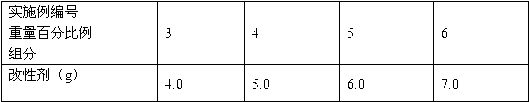

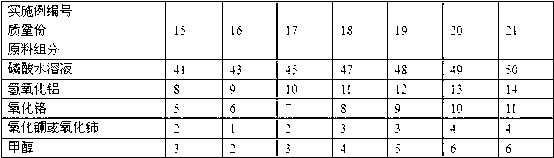

Embodiment 3~6

[0023] A preparation method of modified chromium aluminum phosphate, comprising the following steps: adding 57.98 g of phosphoric acid aqueous solution with a mass percent concentration of 65% in a 500 ml three-necked flask equipped with a booster stirrer and a condensation reflux device, and then adding 10.0 g of aluminum hydroxide g, at 80°C, stir for 20-40min, then add 4.27g of chromium oxide, stir and react until orange transparent solution; adjust the temperature to 90-140°C, add modifier, react for half an hour, then slowly add methanol dropwise 3.0~5.0g, until the oxidation-reduction reaction finishes, keep warm for 60~90min, synthesize green viscous liquid rare earth chromium aluminum phosphate adhesive, promptly make modified chromium aluminum phosphate; The following table:

[0024]

[0025] In the table: the data "4.0" of "modifier" under "embodiment number" is "3" means "taking the quality of modifier as 4.0g", and so on. The modifier is lanthanum oxide or ceri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com