Multi-element internal electrolysis filler and preparation method thereof

An internal electrolysis and multiple technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. High efficiency, improved COD removal, avoidance of clogging and scaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

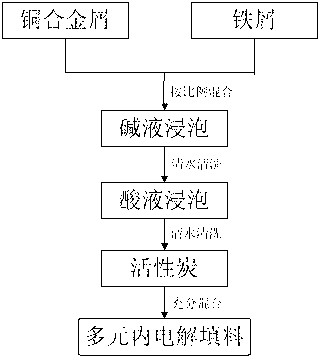

Method used

Image

Examples

Embodiment 1

[0024] Mix 448g of iron shavings (bulk density 1.5g / ml), 44.8g of copper alloy shavings (bulk density 0.225g / ml), and 244g of activated carbon (bulk density 0.49 g / ml) to prepare multi-component internal electrolytic filler A.

[0025] Treat ultrafiltration membrane to prepare enterprise wastewater, the main component is dimethylacetamide, and the daily wastewater production is 56m 3 / d, COD3680~27600mg / L. Add the above-mentioned multi-component internal electrolytic filler A into the reactor, and the results after treatment with the multi-component internal electrolytic filler A are shown in the following table:

[0026] project Influent pH residence time (min) Influent CODCr (mg / L) Effluent CODCr (mg / L) Removal rate% Condition 1 2.2 45 27600 14267 48.3 Condition 2 2.3 45 18400 7767 57.8 Condition 3 2.0 45 7360 1453 80.2 Condition 4 2.2 45 3680 1520 58.7

Embodiment 2

[0028] The washing sewage of dye intermediates and finished toner sewage of a chemical factory, the main components are dimethylformamide, dodecylamine polyoxyethylene ether, inorganic salts and volatile phenols. After water quality analysis, COD26300mg / L, total nitrogen 22.5mg / L, chromaticity 1000. After pretreatment with the multi-component internal electrolytic filler A in Example 1, the effluent COD is about 12000 mg / L, and the BOD / COD is increased from the initial 0.18 to 0.38, which provides feasibility for subsequent anaerobic biodegradation.

Embodiment 3

[0030] 152g of iron shavings, 93g of copper alloy shavings, and 260g of activated carbon were used to make multi-component internal electrolytic filler B.

[0031] Treat the spandex production wastewater of a spandex company, the raw water index is COD2000-3000 mg / L, ammonia nitrogen 50-60mg / L, pH4-5. The working condition of the internal electrolysis reaction is: the hydraulic retention time is 45min, the pH is 2.5, after pretreatment by the multi-component internal electrolysis filler B, the effluent COD510-740 mg / L, the BOD / COD is increased from the initial 0.23 to 0.58, after the internal electrolysis reaction The effluent only needs simple aerobic aeration biochemical treatment to meet the local sewage discharge standard (COD≤100 mg / L).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com