Preparation method of melamine/formaldehyde resin-coating melamine cyanurate (MCA) nano capsule

A technology of melamine cyanurate and melamine, which is applied in the field of materials, can solve the problems of poor compatibility of polymer matrix and easy aggregation of nanoparticles, and achieve the effect of enhancing compatibility and good flame retardant efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

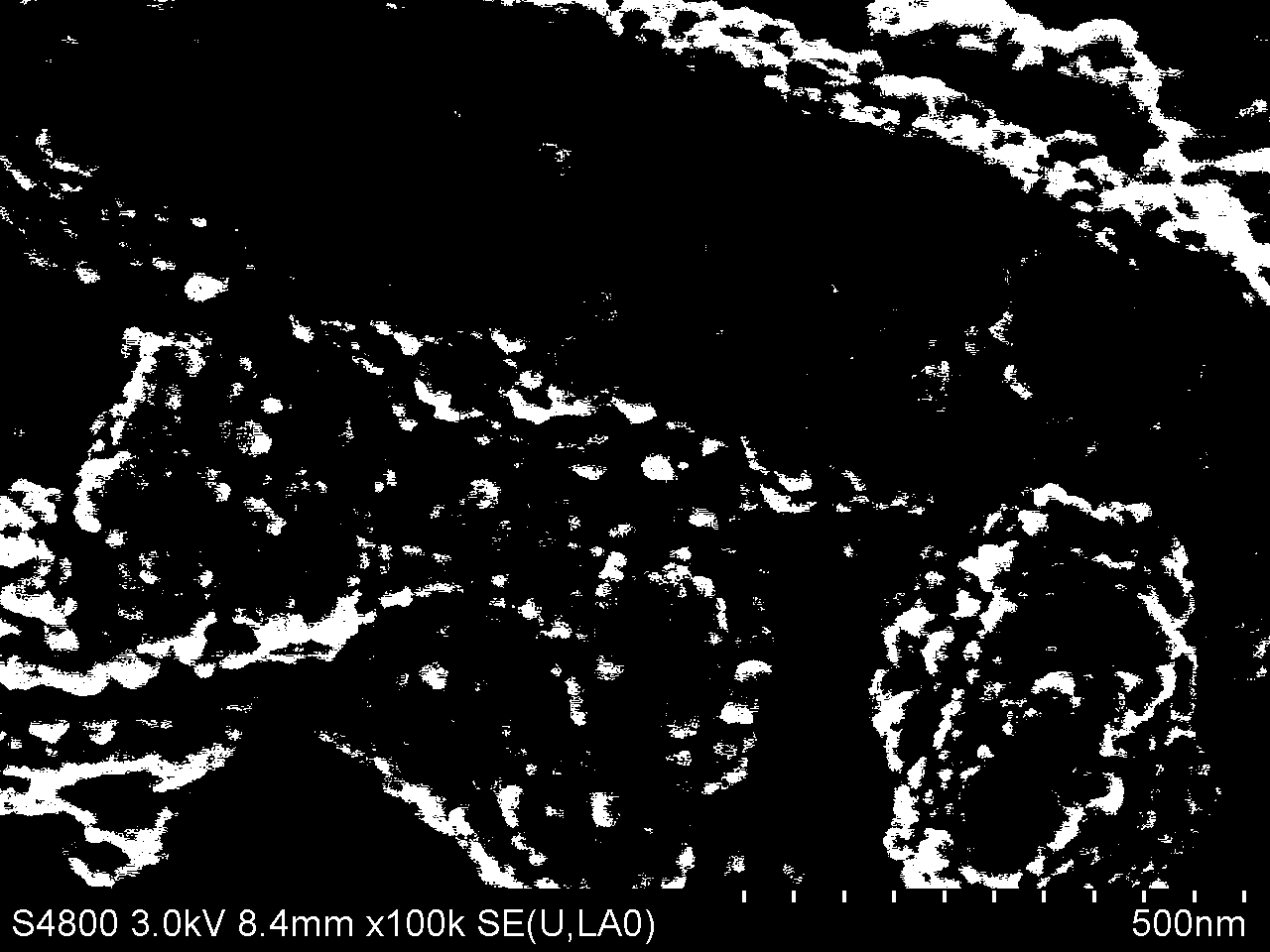

Image

Examples

Embodiment 1

[0019] (1) Preparation of melamine / formaldehyde resin prepolymer:

[0020] Add 12.6g of melamine and 24.33g of 37% formaldehyde (molar ratio is 1:3) and 100ml of distilled water into the three-necked flask. Add a certain amount of sodium hydroxide to adjust the pH of the solution to 8-10, react at 80°C for 0.5h, and cool to room temperature to obtain a colorless and transparent melamine / formaldehyde resin prepolymer solution.

[0021] (2) Preparation of melamine / formaldehyde resin-coated melamine cyanurate (MCA) nanocapsules:

[0022] Add 100g nanometer melamine cyanurate (MCA) and 1g sodium dodecyl sulfate into 200ml distilled water mechanically and ultrasonically disperse for 1 h. Then add the melamine / formaldehyde resin prepolymer prepared in step (1) into the fully dispersed nano-MCA mixed system, use concentrated sulfuric acid to adjust the pH of the solution to around 4-5, react at 80° C. for 2 hours, filter and wash. Vacuum-dried at 80°C for 48 h to obtain dried MCA n...

Embodiment 2

[0024] (1) Preparation of melamine / formaldehyde resin prepolymer:

[0025] Add 12.6g of melamine and 20.27g of 37% formaldehyde (molar ratio 1:2.5) and 100ml of distilled water into the three-necked flask. Add a certain amount of sodium hydroxide to adjust the pH of the solution to 8-10, react at 80°C for 0.5h, and cool to room temperature to obtain a colorless and transparent melamine / formaldehyde resin prepolymer solution.

[0026] (2) Preparation of melamine cyanurate (MCA) nanocapsules coated with melamine / formaldehyde resin:

[0027] Add 100g nanometer melamine cyanurate (MCA) and 3g hexadecyltrimethylammonium bromide into 200ml ethanol mechanically and ultrasonically disperse for 1 h. Then add the melamine / formaldehyde resin prepolymer prepared in step (1) into the fully dispersed nano-MCA mixed system, use concentrated sulfuric acid to adjust the pH of the solution to around 3-4, react at 80° C. for 3 hours, filter and wash. Vacuum-dry at 80°C for 48 h to obtain dried...

Embodiment 3

[0029] (1) Preparation of melamine / formaldehyde resin prepolymer:

[0030] Add 12.6g of melamine and 32.44g of 37% formaldehyde (molar ratio of 1:4) and 100ml of distilled water into the three-necked flask. Add a certain amount of sodium hydroxide to adjust the pH of the solution to 8-10, react at 80°C for 0.5h, and cool to room temperature to obtain a colorless and transparent melamine / formaldehyde resin prepolymer solution.

[0031] (2) Preparation of melamine cyanurate (MCA) nanocapsules coated with melamine / formaldehyde resin:

[0032] Add 100g of nanometer melamine cyanurate (MCA) and 2g of nonylphenol polyoxyethylene ether into 200ml of ethanol and distilled water mixed solvent (volume ratio 1:1) and mechanically and ultrasonically disperse for 1 h. Then add the melamine / formaldehyde resin prepolymer prepared in step (1) into the fully dispersed nano-MCA mixed system, use concentrated sulfuric acid to adjust the pH of the solution to around 3-4, react at 80°C for 2.5h, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com