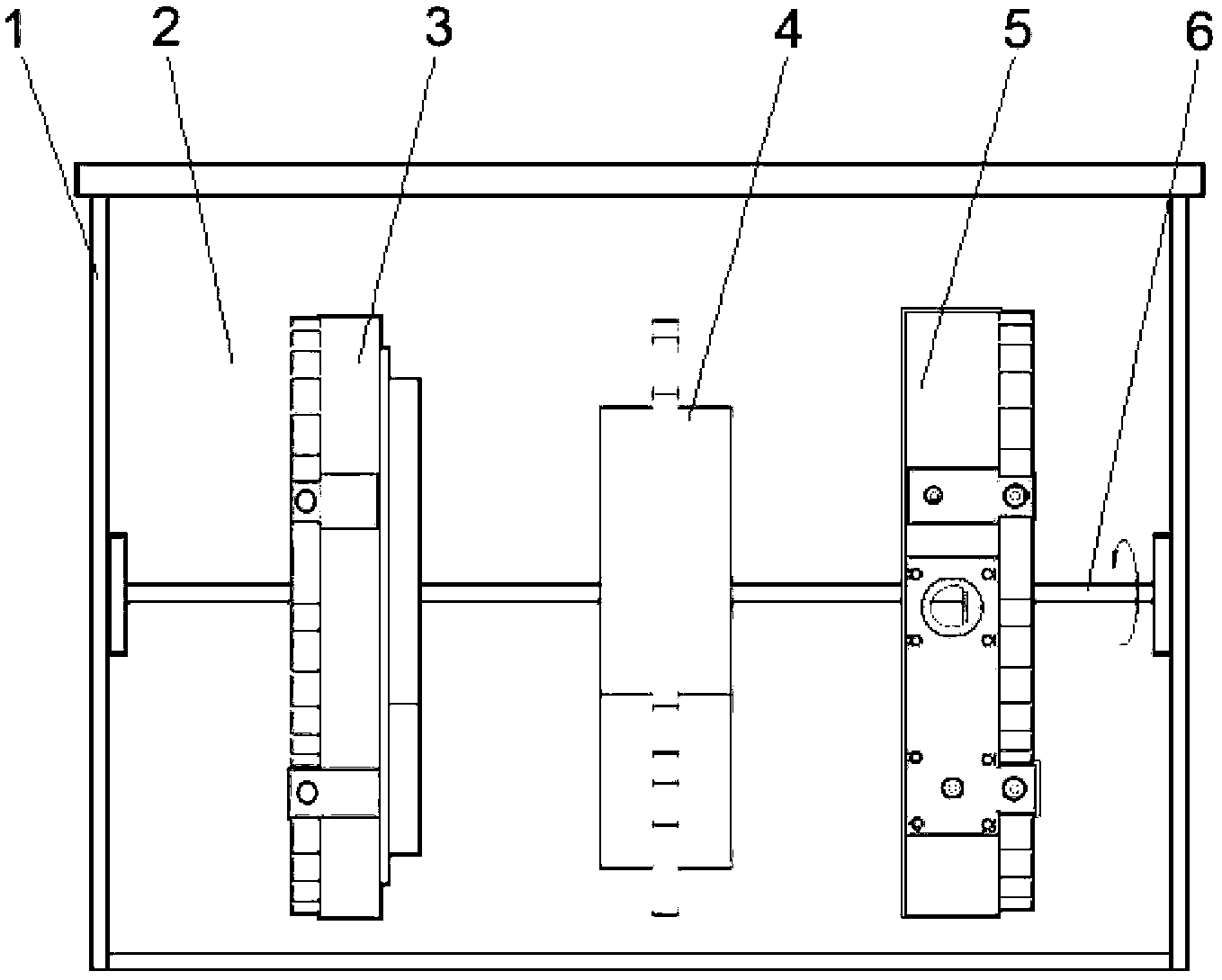

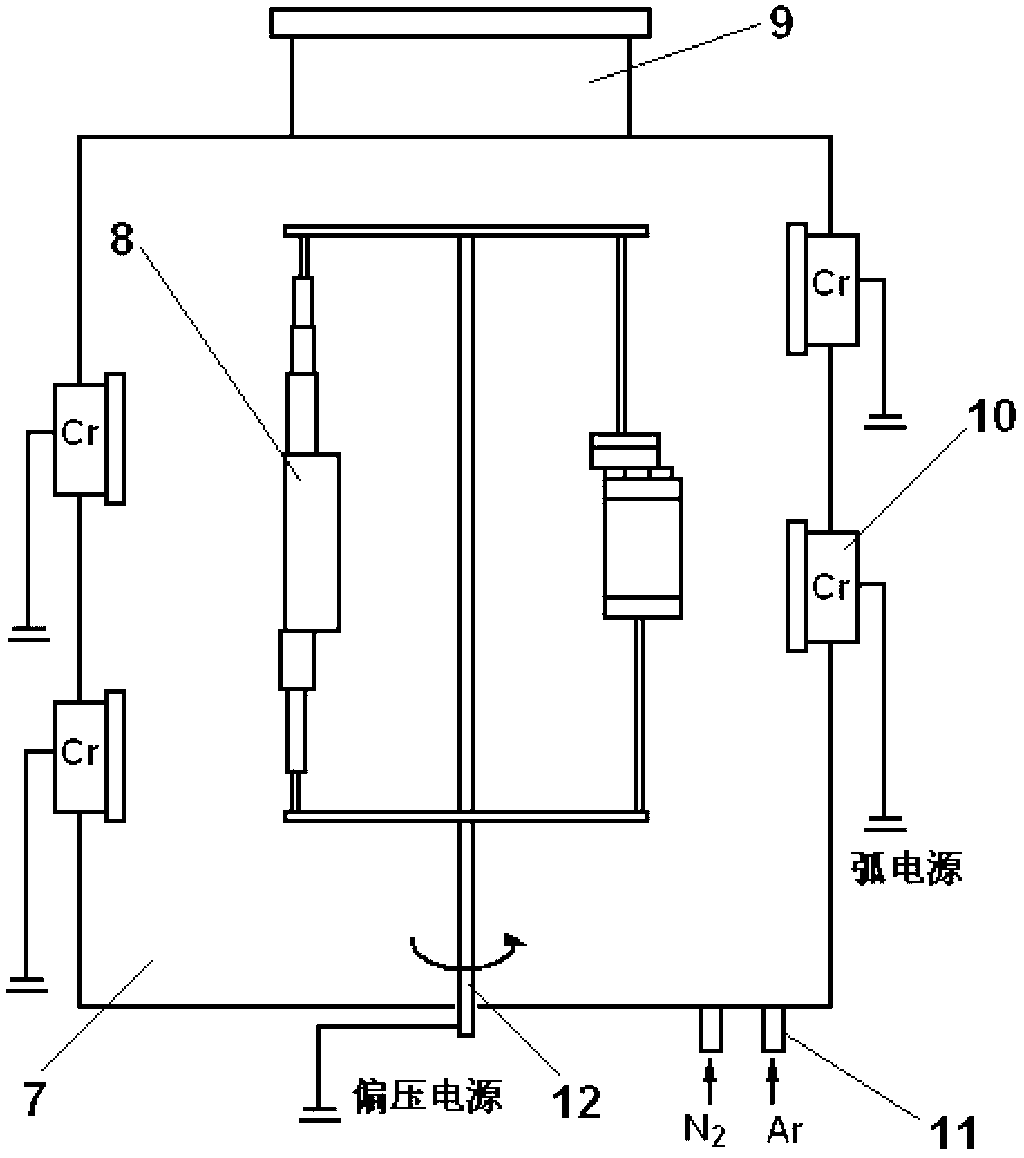

Preparation method of protective coating of dry scroll vacuum pump

A technology for dry vacuum pumps and protective coatings, which is applied in coatings, vacuum evaporation coatings, and metal material coating processes, etc. Spin-dry pump service life and application field, poor corrosion resistance and wear resistance, etc., to achieve the effect of flexible plating, simple structure, improved corrosion resistance and mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] In this embodiment, nickel-phosphorus coating is applied on the surface of aluminum alloy rotor and stator A / B by electroless plating, and nickel-phosphorus coating is applied on the surface of aluminum alloy rotor and stator by electroless plating. The process is: degreasing → water washing → primary acid Corrosion → water washing → primary zinc immersion → water washing → secondary acid etching → water washing → secondary zinc immersion → water washing → chemical nickel plating phosphorus → water washing → anhydrous ethanol washing → drying → fluorine coating sealing → plasticization, of which:

[0065] (1) Degreasing

[0066] Remove the oil on the surface of the rotor and stator A / B material, the formula of the aluminum alloy degreasing liquid is as follows:

[0067] Na 2 CO 3 15~20g / L, Na 3 PO 4 12H 2 O20~30g / L, Na 2 SiO 3 10~15g / L, OP emulsifier 1~3g / L (OP emulsifier, commercially available product, source: Shenyang Chemical Reagent Store), solvent is water;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com