A kind of preparation method of organic thin film transistor

An organic thin film and transistor technology, applied in the field of organic thin film transistor preparation, can solve the problems of limiting the application of rubrene, it is difficult to obtain hole mobility, and it is difficult to form a highly ordered crystalline film, so as to improve the π-π The effect of improving carrier transfer efficiency and improving carrier transport efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] First step SiO 2 / Si substrate pretreatment: the cut SiO 2 / Si substrate was ultrasonically cleaned in acetone for 10 minutes, dried with a nitrogen gun and then placed in H 2 SO 4 (98%): H 2 o 2 (30%) = 7:3 solution, treated at 100°C for 1 hour; take it out, wash it with deionized water, dry it with a nitrogen gun, and place it in NH 3 (30%): H 2 o 2 (30%): H 2 O=1:1:5 solution, treated at 70°C for 20 minutes, cleaned with deionized water after taking it out, blown dry with nitrogen gun, and the cleaning of the substrate was completed;

[0019] The second step is vacuum evaporation of rubrene to form a film: the above pretreated SiO 2 / Si substrate is placed in a vacuum evaporation apparatus, and the vacuum pressure is 1×10 -4 Under Pa, the substrate temperature is 25°C-110°C to evaporate 80nm rubrene (four parallel experiments are 25°C, 60°C, 90°C, 110°C), and the evaporation rate is 2~4 nm / min;

[0020] Step 3 Vacuum evaporation of metal electrodes: Evapo...

Embodiment 2

[0024] SiO 2 / Si substrate pretreatment, as embodiment 1;

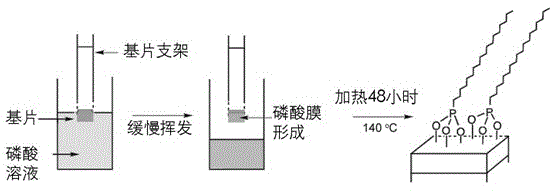

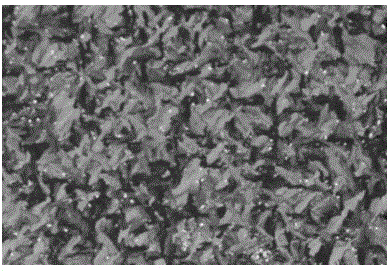

[0025] Self-assembly treatment of the substrate: Dissolve n-octadecylphosphoric acid in tetrahydrofuran to prepare a 1mmol / L solution, such as figure 2 As shown, using the pulling method (the so-called pulling method is to make the solvent evaporate naturally on SiO 2 / Si substrate to form a uniform film, grown n-octadecyl phosphate film) in the pretreated SiO 2 N-octadecyl phosphoric acid film was grown on the Si substrate, and reacted in a vacuum oven at 140°C for 48 hours. During this process, the phosphoric acid film formed a stable chemical bond with the silicon dioxide surface; then it was taken out and cleaned with tetrahydrofuran ultrasonically. SiO 2 / Si substrate for 5 minutes, the substrate after cleaning is smooth and smooth, and a uniformly distributed n-octadecyl phosphoric acid layer can be seen under the atomic force microscope, with a thickness of 2.4~4.8 nm;

[0026] Vacuum evaporation of organi...

Embodiment 3

[0031] SiO 2 / Si substrate pretreatment, as embodiment 1;

[0032] The self-assembly process of substrate, as embodiment 2;

[0033] Vacuum evaporation organic template layer: the above self-assembled substrate with n-octadecyl phosphoric acid film is placed in a vacuum evaporation apparatus, and the vacuum pressure is 6.0×10 -5 Under Pa, at a substrate temperature of 60°C, vapor-deposit a 5nm layer of 6,13-pentacenepyrazine (DAP) molecules at a speed of 2-4 nm / min;

[0034] Vacuum deposition of rubrene: rubrene is deposited without opening the vacuum chamber, the substrate temperature is 90°C, and 80nm rubrene is thermally deposited as the semiconductor layer;

[0035] Vacuum evaporation of metal electrodes was carried out as in Example 1, and a rubrene organic thin film transistor device was prepared.

[0036]The rubrene organic thin film transistor prepared by evaporating DAP at a substrate temperature of 60°C shows a hole transport performance of 6.8×10 -1 cm 2 / V·s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com