Method for preparing isophorone diamine

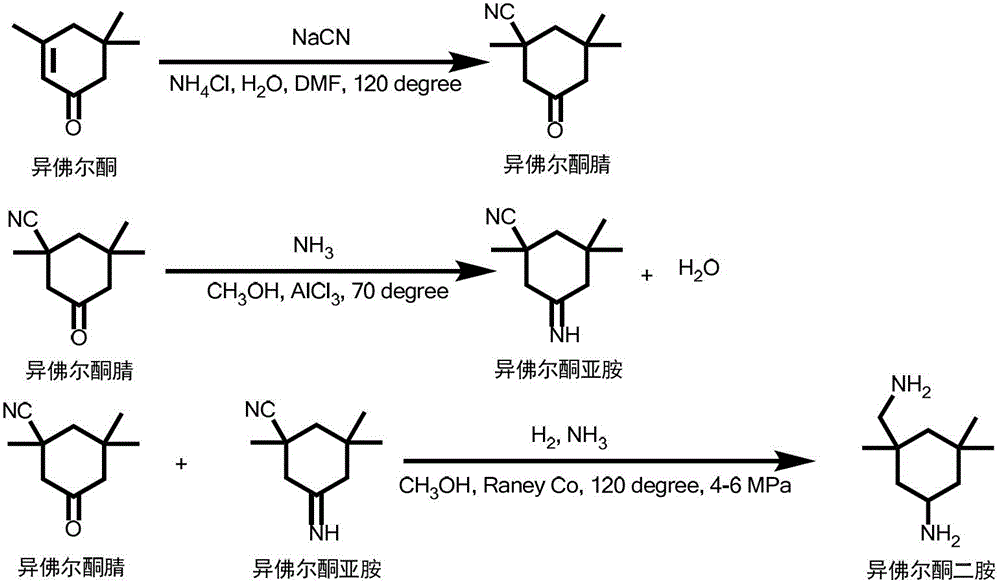

The technology of isophorone diamine and isophorone nitrile is applied in the field of preparation and optimization of catalytic reaction process, which can solve the problems of low yield of IPDA, and achieve the effects of long catalyst life, uniform dispersion and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

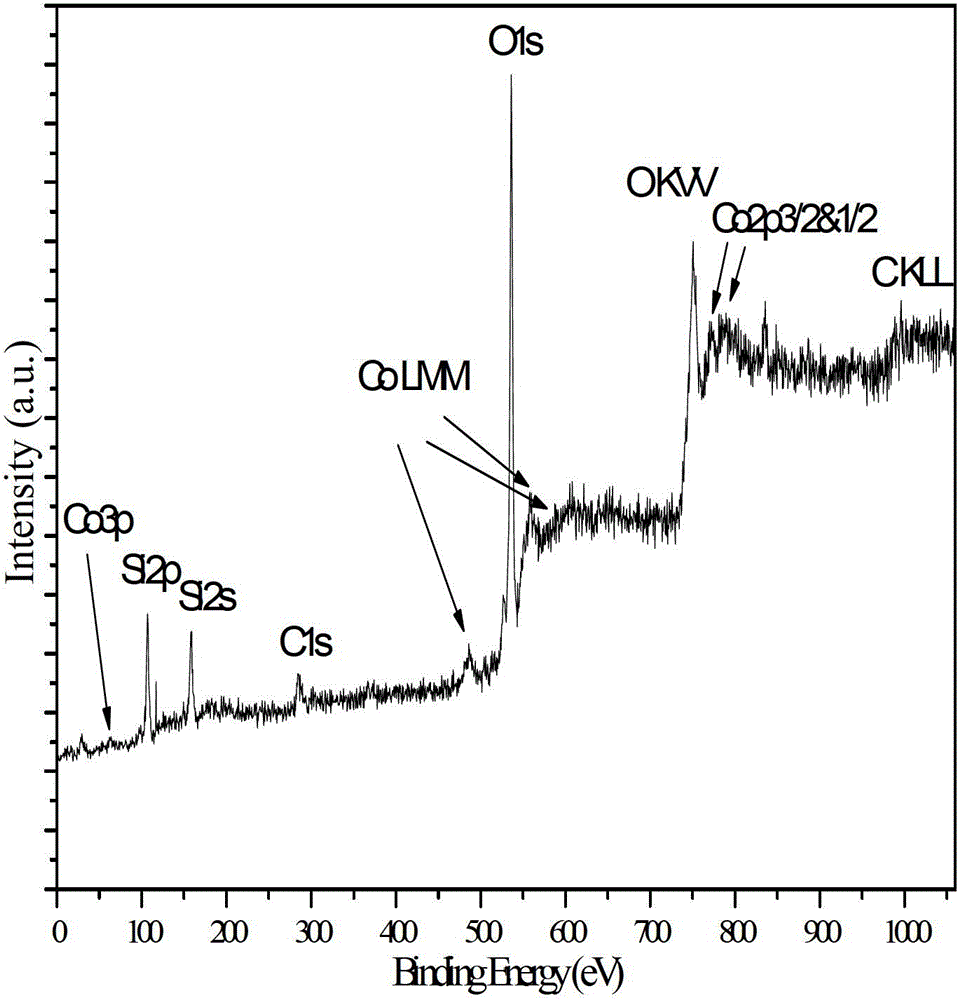

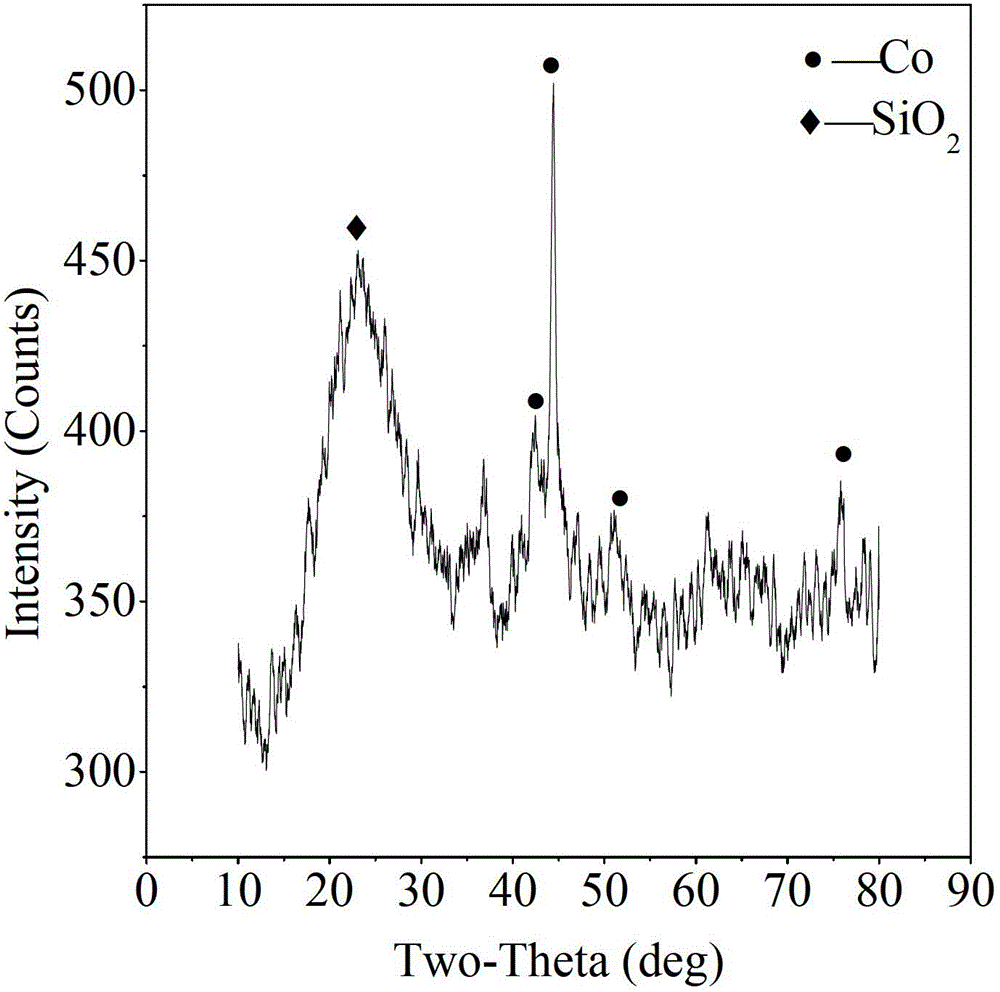

[0035] Embodiment 1: Sol-gel method prepares metallic cobalt catalyst

[0036] (1) Metal cobalt catalyst with metal cobalt loading of 10wt%:

[0037] According to the ratio of ethyl orthosilicate: absolute ethanol: deionized water = 1:4:10 (the ratio of the amount of substances), measure 37.3ml (0.1665mol) ethyl orthosilicate and add it to 38.9ml of absolute ethanol Alcoholic solution of ethyl orthosilicate made in the medium, weigh 5.48g Co(NO 3 ) 2 ·6H 2 O (0.0188mol) was dissolved in 30.0ml deionized water to make an aqueous solution of cobalt nitrate, and the aqueous solution of cobalt nitrate was slowly added dropwise to the absolute ethanol solution of tetraethyl orthosilicate to make a mixed solution, which was stirred while dropping, 5 The dropwise addition is completed within 1 minute, and after the dropwise addition is completed, use 2mol / L dilute nitric acid and 2mol / L ammonia water to adjust the pH of the mixture to 3.5. After adjusting the pH, put the mixed so...

Embodiment 2

[0041] The preparation process of the catalyst is the same as in Example 1, except that dilute nitric acid and ammonia water are used to adjust the pH to 4 at the end, and other conditions are the same. Add 500mg of the activated cobalt metal catalyst (metal cobalt load: 10wt%) prepared in step (1) into a 100ml autoclave, then add 25ml of anhydrous methanol, 2.5g of isophorone nitrile, and close the reactor The air in the reaction kettle is purged and replaced by nitrogen gas afterward, and then the ammonia gas is passed to make the reaction kettle pressure reach 0.1MPa, and then the hydrogen gas is passed to make the reaction kettle pressure be 8MPa, the reaction temperature is 120° C., and the reaction is 8h. Other operations are the same as in Example 1. The conversion rate of IPN is 100%, and the yield of IPDA is 85.5%.

Embodiment 3

[0043] The preparation process of the catalyst is the same as in Example 1, except that dilute nitric acid and ammonia water are used to adjust the pH=4.5 at the end, and other conditions are the same. Add 750mg of the activated metal cobalt catalyst prepared in step (1) (the metal cobalt load is 10wt%) into a 100ml autoclave, then add 40ml of anhydrous methanol, 2.5g of isophorone nitrile, and close the reactor The air in the reaction kettle is purged and replaced by nitrogen gas afterward, and then the ammonia gas is passed to make the reaction kettle pressure reach 0.1MPa, and then the hydrogen gas is passed to make the reaction kettle pressure be 8MPa, the reaction temperature is 120° C., and the reaction is 8h. Other operations are the same as in Example 1. The conversion rate of IPN is 100%, and the yield of IPDA is 92.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com