Method for quantitative determination of macroelements and trace elements comprising arsenic, tin and antimony in carbon steel or low alloy steel

A low-alloy steel and constant element technology, applied in the field of quantitative analysis in analytical chemistry, can solve the problems of difficult selection of background measurement points and high trace analysis results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

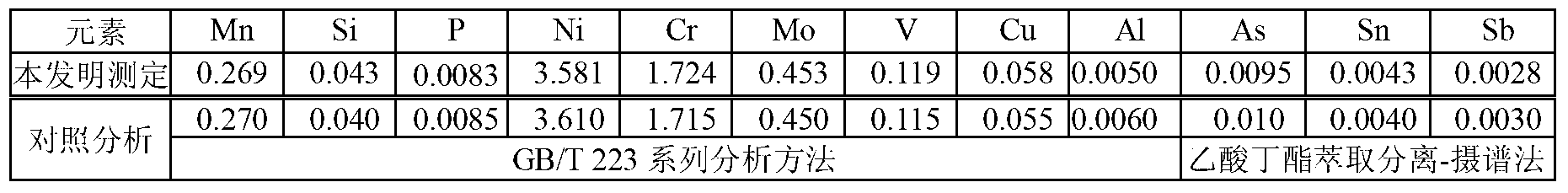

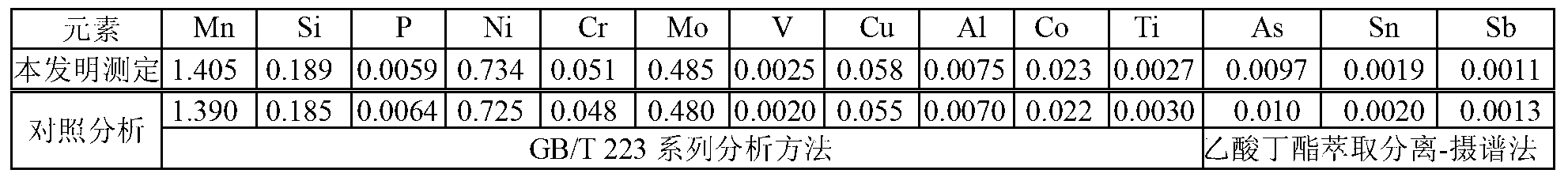

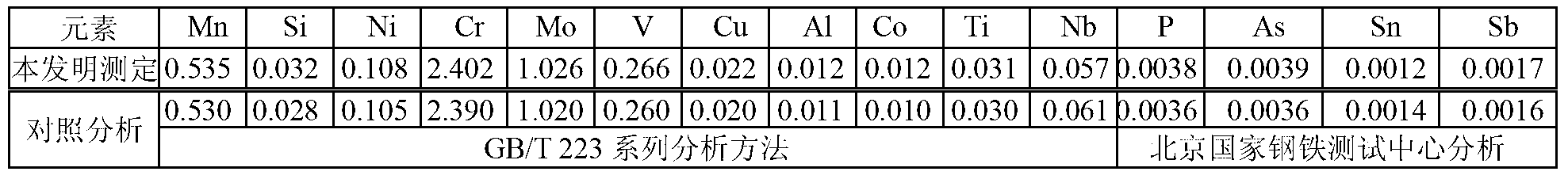

Examples

Embodiment 1

[0036] Preparation of dilute aqua regia: Take 1500ml of hydrochloric acid (ρ=1.19g / ml), 500ml of nitric acid (ρ=1.42g / ml), and 2000ml of water and mix well.

[0037] Preparation of standard series solutions: choose 4 standard steels of carbon steel and low alloy steel sold at home and abroad, make manganese, silicon, phosphorus, nickel, chromium, molybdenum, vanadium, copper, aluminum, titanium, niobium, tungsten, cobalt , arsenic, tin, antimony and other elements have appropriate gradients, weigh 0.1000g of standard steel, add 20ml of dilute aqua regia, add 5 drops of hydrogen peroxide, and heat at 125°C. After the sample is completely dissolved, cool it and rinse with water Dilute to 100ml, shake well, and prepare a series of standard solutions (including a reagent blank solution that comes with the sample).

[0038] Preparation of sample solution: Weigh 0.1000g steel sample, add 20ml dilute aqua regia, drop 5 drops of hydrogen peroxide, heat at 125°C, after the sample is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com