Preparation method for in situ self-assembled organic/inorganic hybrid membrane based on coordination

A technology of self-assembly and hybrid membrane, which is applied in the field of membrane separation, can solve problems such as agglomeration, loss of inorganic nanoparticles, and poor dispersion of inorganic nanoparticles, and achieve improved solvent resistance and pollution resistance, improved performance, and increased ratio The effect of surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

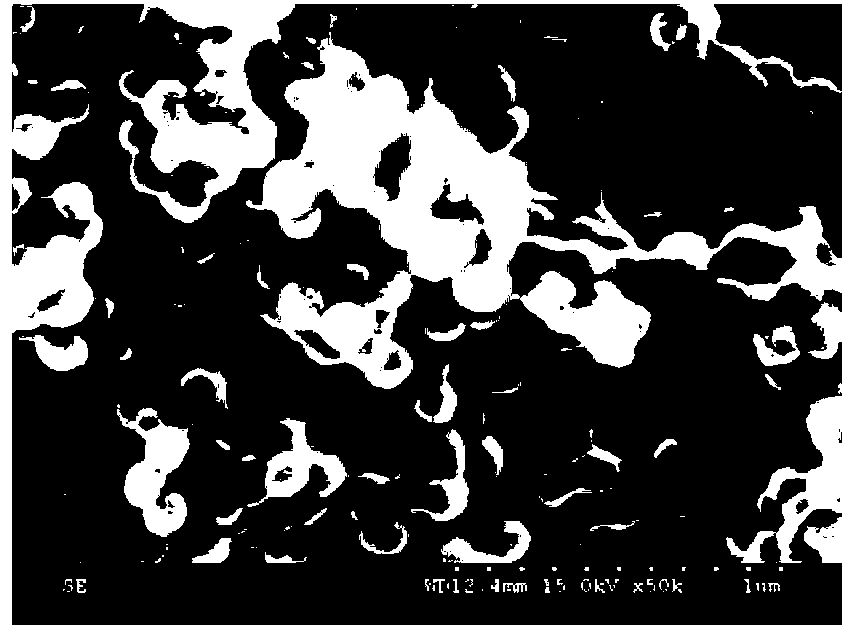

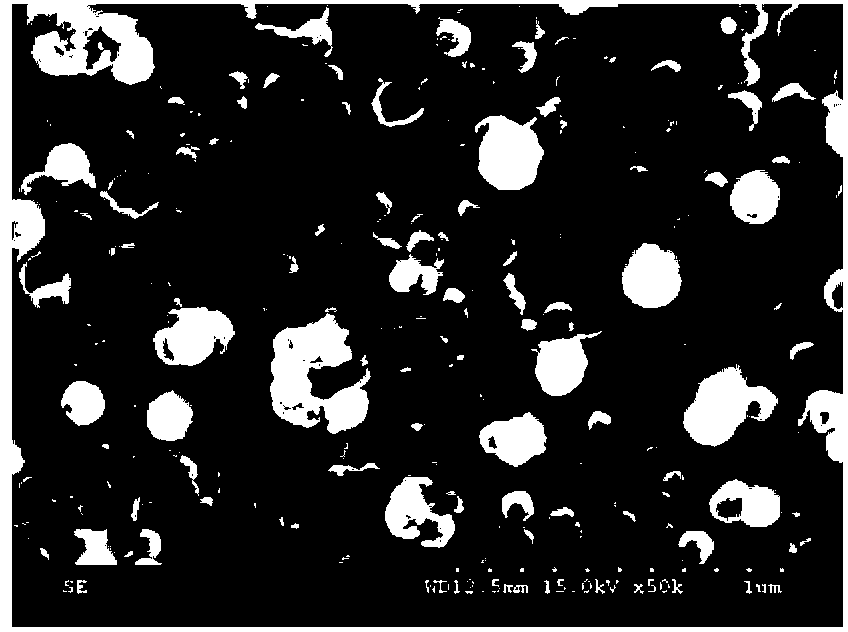

Image

Examples

Embodiment 1

[0028] The base membrane is polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 20cm 2 , the polyelectrolyte used is polystyrene sulfonate sodium (PSS, with a molecular weight of 1 million); the metal ion is zinc nitrate hexahydrate (Zn(NO 3 )·6H 2 O, the molecular weight is 297.49); the organic ligand is 2-methylimidazole (C 4 h 6 N 2 , with a molecular weight of 82.10). The solvents of zinc nitrate hexahydrate and 2-methylimidazole are methanol, and the solvent of sodium polystyrene sulfonate is water.

[0029] Assembly conditions and methods:

[0030] (1) Use deionized water to make sodium polystyrene sulfonate into 500ml of a 3wt% solution, and let it stand for degassing; use methanol to make 500ml of a 0.05mol / L solution of zinc nitrate hexahydrate, and let it stand for degassing; Make 2-methylimidazole into 500ml of 0.4mol / L solution with methanol, let it stand for defoaming;

[0031]...

Embodiment 2

[0041] The base membrane is polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 20cm 2, the polyelectrolyte used is polystyrene sulfonate sodium (PSS, with a molecular weight of 1 million); the metal ion is zinc nitrate hexahydrate (Zn(NO 3 )·6H 2 O, the molecular weight is 297.49); the organic ligand is 2-methylimidazole (C 4 h 6 N 2 , with a molecular weight of 82.10). The solvents of zinc nitrate hexahydrate and 2-methylimidazole are methanol, and the solvent of sodium polystyrene sulfonate is water.

[0042] Assembly conditions and methods:

[0043] (1) Make sodium polystyrene sulfonate into 500ml of a 0.3wt% solution with deionized water, and let it stand for defoaming; make zinc nitrate hexahydrate into 500ml of a 0.05mol / L solution with methanol, let it stand for defoaming; Make 2-methylimidazole into 500ml of a 0.4mol / L solution with methanol, and let it stand for defoaming.

[0044...

Embodiment 3

[0055] The base membrane is polyacrylonitrile (PAN) material, a flat ultrafiltration membrane with a molecular weight cut-off of 20,000 and a membrane area of 20cm 2 , the polyelectrolyte used is polystyrene sulfonate sodium (PSS, with a molecular weight of 1 million); the metal ion is zinc nitrate hexahydrate (Zn(NO 3 )·6H 2 O, the molecular weight is 297.49); the organic ligand is 2-methylimidazole (C 4 h 6 N 2 , with a molecular weight of 82.10). The solvents of zinc nitrate hexahydrate and 2-methylimidazole are methanol, and the solvent of sodium polystyrene sulfonate is water.

[0056] Assembly conditions and methods:

[0057] (1) Make sodium polystyrene sulfonate into 500ml of a 0.3wt% solution with deionized water, and let it stand for defoaming; make zinc nitrate hexahydrate into 500ml of a 0.5mol / L solution with methanol, let it stand for defoaming; Make 2-methylimidazole into 500ml of 4mol / L solution with methanol, let stand for defoaming;

[0058] (2) In or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com