Method for producing active carbon from salix mongolica branches through pyrolysis

A technology for producing activated carbon and activated carbon, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of waste of resources, environment, pollution, etc., and achieve the effect of increasing added value, reducing manufacturing costs, and broadening development space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

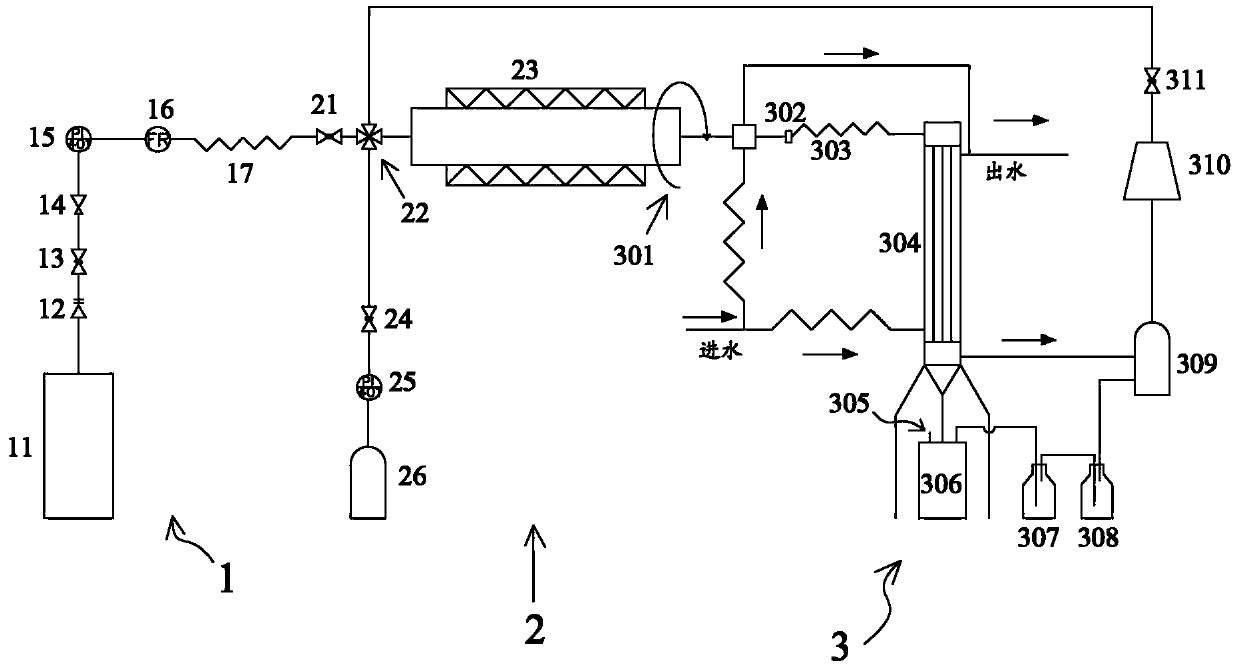

Method used

Image

Examples

Embodiment 1

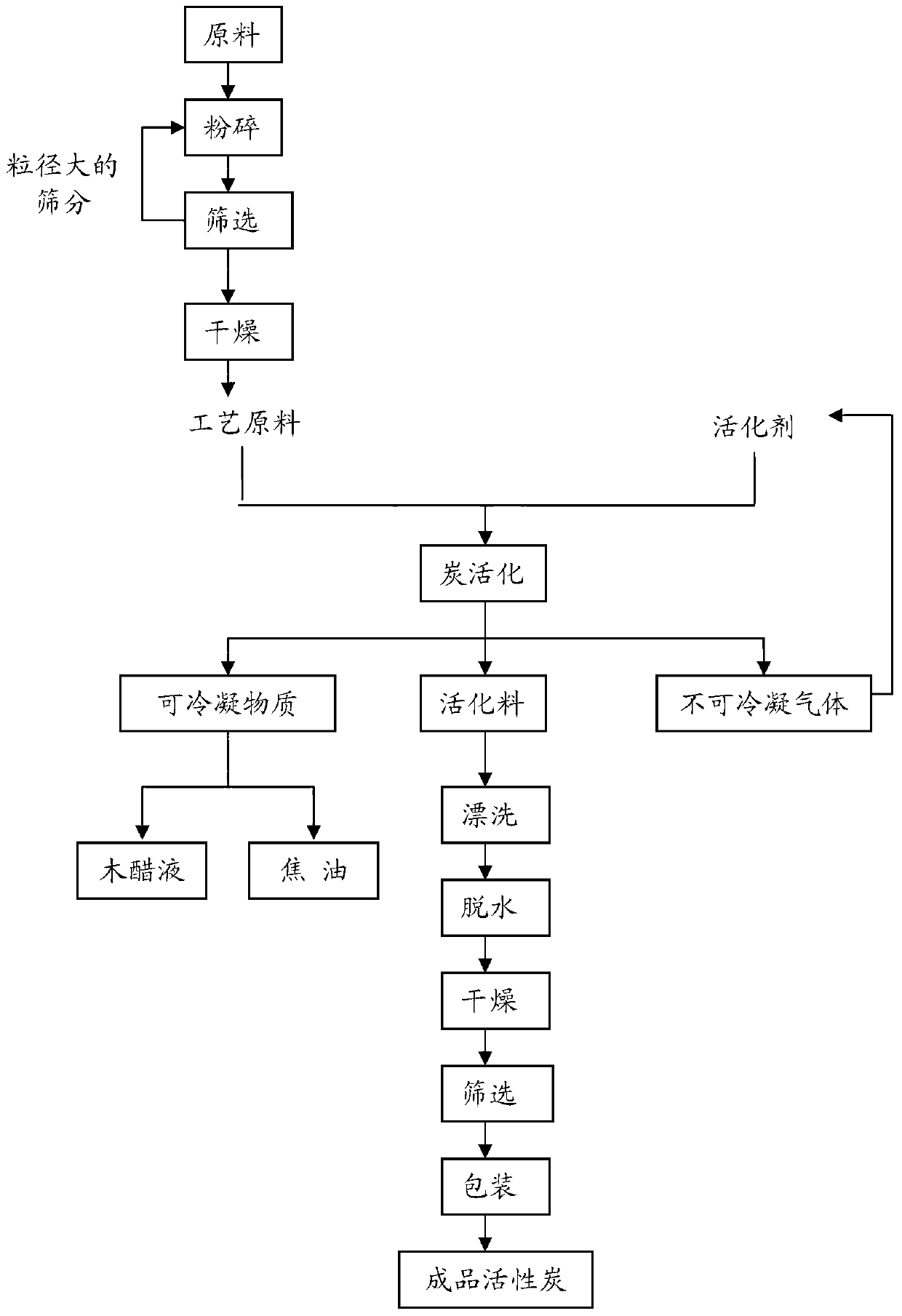

[0036] A method for pyrolyzing salix twigs to produce activated carbon, comprising the following steps:

[0037] (1) Raw material preparation and program setting stage: After removing impurities from Salix twigs, air-dry or dry them and crush them, then crush the Salix twig wood chips to a certain specification (the crushing specification can be selected as less than 18-mesh standard sieve) Put it into the rotary kiln, close the feeding port, and set the heating rate and temperature range of the rotary kiln. Among them, the first stage: the heating rate is 1°C / min, and the temperature range is 0-600°C; the second stage: the carbon activation temperature is 700°C, the heating rate is 1°C / min, and the holding time is 5h; the third stage: stop heating and start Cool down program.

[0038] (2) Pyrolysis and reactant collection stage: According to the temperature setting of the first stage, after the carbonization is completed, CO is introduced 2Gas activator, the flow rate is se...

Embodiment 2

[0041] A method for pyrolyzing salix twigs to produce activated carbon, comprising the following steps:

[0042] (1) Raw material preparation and program setting stage: After removing impurities from the willow wood, air-dry or dry it and crush it, put the sawdust material crushed to a certain size into the rotary furnace, close the feeding port, and set the The heating rate and temperature range of the converter. Among them, the first stage: the heating rate is 15°C / min, and the temperature range is 0-500°C; the second stage: the heating rate is 10°C / min, the carbon activation temperature is 800°C, and the holding time is 4h; the third stage: stop heating and start Cool down program.

[0043] (2) Pyrolysis and reactant collection stage: according to the temperature setting of the first stage, after the carbonization is completed, the gas activator CO is introduced 2 , the flow rate is set to 50L / h, the gas pressure inside the rotary furnace is less than 0.40MPa, the rotatin...

Embodiment 3

[0046] A method for producing activated carbon by pyrolysis of salix twigs, comprising the following steps:

[0047] (1) Raw material preparation and program setting stage: After removing impurities from the willow wood, air-dry or dry it and crush it, put the sawdust material crushed to a certain size into the rotary furnace, close the feeding port, and set the The heating rate and temperature range of the converter. Among them, the first stage: the heating rate is 15°C / min, and the temperature range is 0-1200°C; the second stage: the carbon activation temperature is 1200°C, and the holding time is 1h; the third stage: stop heating and start the cooling program.

[0048] (2) Pyrolysis and reactant collection stage: According to the temperature setting of the first stage, after the carbonization is completed, the gas activator CO is introduced 2 , the flow rate is set to 90L / h, the gas pressure inside the rotary furnace is less than 0.40MPa, the rotating speed of the rotary f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com