Glaz-use potassium feldspar powder and preparation method thereof

The technology of potassium feldspar powder and yellow potassium feldspar is applied in the field of preparation of low sodium potassium feldspar powder for glaze, and can solve the problems of increasing the production cost of ceramic frit, narrow melting temperature range of potassium feldspar, and high price of chemical raw materials , to achieve the effect of shortening the sintering time, increasing the melting temperature range, good dispersion ability and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A basic preparation method of potassium feldspar powder for glaze of the present invention, its steps are as follows:

[0032] (1) Select and wash the raw materials white potassium feldspar, yellow potassium feldspar and gray potassium feldspar respectively, and remove impurities and useless minerals according to product requirements;

[0033] (2) Dry the raw materials until the moisture in the raw ore is less than 3%;

[0034] (3) Use a crusher to crush raw materials to obtain ore, and pass the ore into the drum iron remover to remove mechanical iron and strong magnetic minerals;

[0035] (4), according to the parts by weight of each component, the raw materials of 3.5-5 parts of white potassium, 3-3.5 parts of yellow potassium, and 2-3 parts of gray potassium are used for batching, and then homogenized to obtain mixed mineral materials;

[0036] (5) Grind the mixed mineral materials through a dry ball mill, and then classify them by air flow;

[0037] (6) After grad...

Embodiment 1

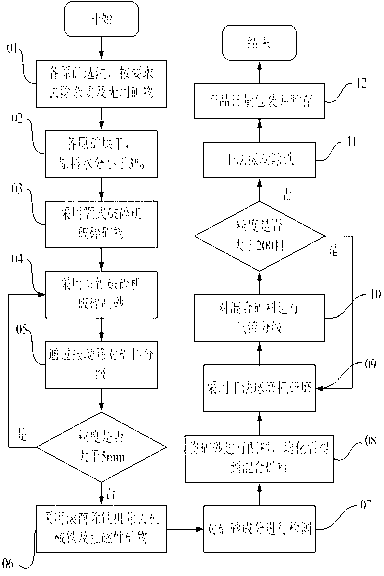

[0042] as attached figure 1 As shown, the concrete steps of the technological process of the present embodiment are as follows:

[0043] Step 01: Separately wash the raw ore white potassium feldspar, yellow potassium feldspar, and gray potassium feldspar, and remove impurities and useless minerals according to product requirements.

[0044] Step 02: Dry each raw ore until the moisture in the raw ore is less than 3%.

[0045] Step 03: Use a 400*600 jaw crusher to crush each raw ore, and adjust the output particle size to 40mm.

[0046] Step 04: Use a cone crusher to crush and make sand, and adjust the output particle size to 5mm.

[0047] Step 05: Classify the ore through the vibrating screen. The ore with a particle size > 5mm is returned to the cone crusher for further crushing, and the ore with a particle size < 5mm enters step 06.

[0048] Step 06: Use a drum iron remover to remove mechanical iron and strong magnetic minerals, and adjust the magnetic field strength to 0....

Embodiment 2

[0062] The concrete steps of the technical process of this embodiment are as follows:

[0063] Step 01: Separately wash the raw ore white potassium feldspar, yellow potassium feldspar, and gray potassium feldspar, and remove impurities and useless minerals according to product requirements.

[0064] Step 02: Dry each raw ore until the moisture in the raw ore is less than 3%.

[0065] Step 03: Use a 400*600 jaw crusher to crush each raw ore, and adjust the output particle size to 40mm.

[0066] Step 04: Use a cone crusher to crush and make sand, and adjust the output particle size to 5mm.

[0067] Step 05: Classify the ore through the vibrating screen. The ore with a particle size > 5mm is returned to the cone crusher for further crushing, and the ore with a particle size < 5mm enters step 06.

[0068] Step 06: Use a drum iron remover to remove mechanical iron and strong magnetic minerals, and adjust the magnetic field strength to 1.0 Tesla.

[0069] Step 07: Test the compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Magnetic field strength | aaaaa | aaaaa |

| Magnetic field strength | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com