Application of multi-component super-molecule hydrogel as adhesion agent

A supramolecular hydrogel and adhesive technology, applied in the direction of non-polymer adhesive additives, adhesives, adhesive types, etc., can solve the problem of weak adhesive force, irreversible adhesive behavior, and only one-time use Use and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1, preparation supramolecular hydrogel

[0064] 1) Take 1 mL of oxidized carbon nanotube aqueous solution with a concentration of 4 mg / mL, add 1 mL of polyethylene polyamine, seal the system and heat it in a water bath at 50 °C for 30 s;

[0065] 2) The resulting mixture was kept at 12°C for 10 minutes to obtain a carbon nanotube / polyethylene polyamine supramolecular hydrogel.

[0066] Then, according to the above steps, by adjusting the mass ratio of oxidized carbon nanotubes to polyethylene polyamine (1:33-3500) and the mass percentage of water (25%-90%), a series of hydrogels with compositions were prepared. .

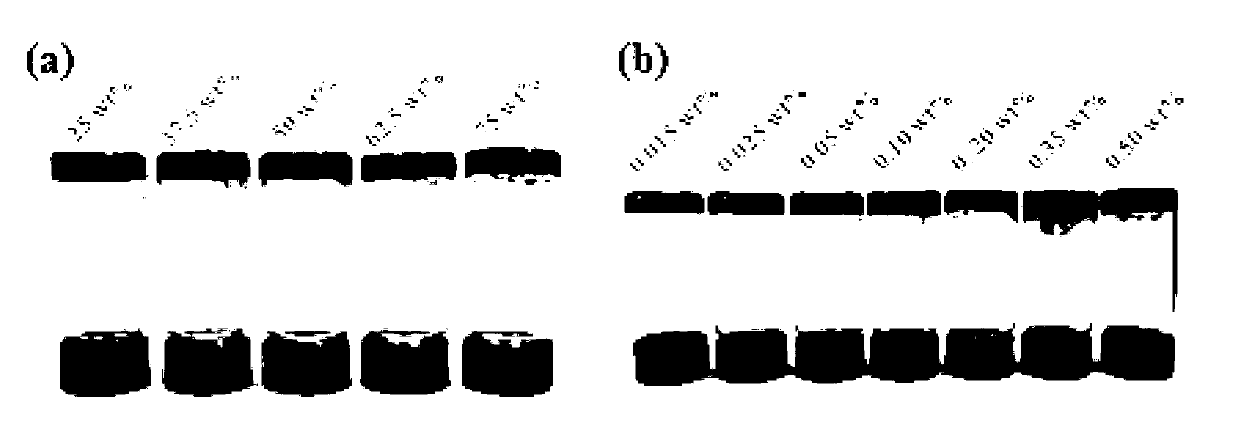

[0067] figure 1 It is a digital photo of the carbon nanotube / polyethylene polyamine supramolecular hydrogel obtained in Example 1.

[0068] in figure 1 (a) In the hydrogel shown, the concentration of oxidized carbon nanotubes is 0.2wt%, and the water content is 25wt%, 37.5wt%, 50wt%, 62.5wt% and 75wt% from left to right; figure 1 (b) The water...

Embodiment 2

[0073] Embodiment 2, preparation supramolecular hydrogel

[0074] 1) Take 1 mL of oxidized carbon nanotube aqueous solution with a concentration of 4 mg / mL, add 1 mL of branched polyethyleneimine with a molecular weight of 300, seal the system and heat it in a water bath at 50 °C for 30 s;

[0075] 2) The resulting mixture was kept at 12°C for 6 hours to obtain a carbon nanotube / polyethyleneimine supramolecular hydrogel.

[0076] Then, according to the above steps, a series of hydrogels were prepared by adjusting the mass ratio of carbon nanotubes to polyethyleneimine (1:33-3500) and the mass percentage of water (25%-75%).

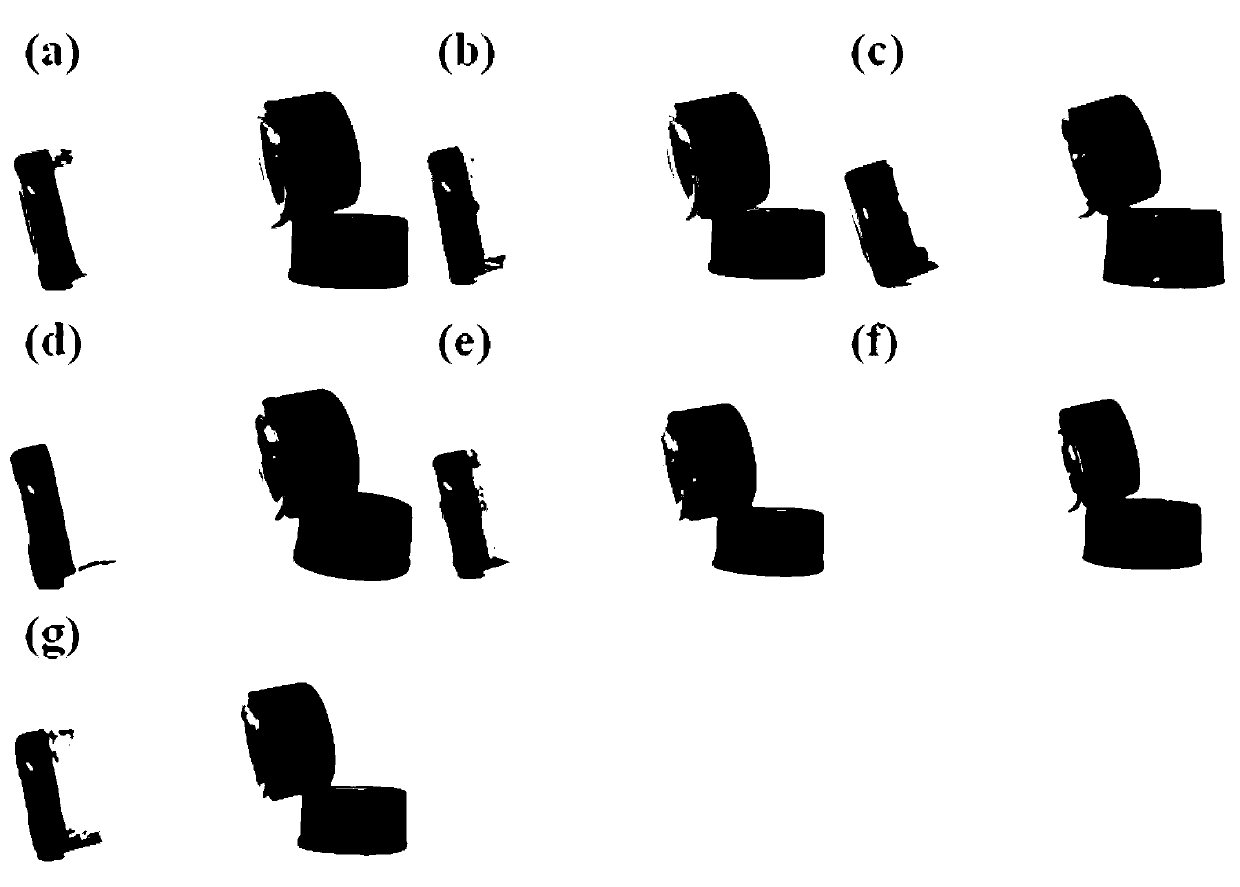

[0077] A digital photo of a hydrogel of a composition prepared in this example (the concentration of oxidized carbon nanotubes is 0.2wt%, the water content is 50wt%, and the mass ratio of oxidized carbon nanotubes to polyethyleneimine is 1:250) is as follows figure 2 (b) shown.

Embodiment 3

[0078] Embodiment 3, preparation supramolecular hydrogel

[0079] 1) Take 1mL of graphene oxide aqueous solution with a concentration of 3mg / mL, add 1mL of polyethylene polyamine, seal the system and heat it in a water bath at 50°C for 30s;

[0080] 2) The resulting mixture was kept at 12°C for 12 hours to obtain a graphene / polyethylene polyamine supramolecular hydrogel.

[0081] Then, according to the above steps, a series of hydrogels were prepared by adjusting the mass ratio of graphene oxide to polyethylene polyamine (1:33-3500) and the mass percentage of water (25%-90%).

[0082] A digital photo of a composition of hydrogel prepared in this embodiment (the concentration of carbon nanotubes is 0.15wt%, the water content is 50wt%, and the mass ratio of graphene oxide to polyethylene polyamine is 1:333.3 is as follows figure 2 (c) shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com