Method for reducing nitrogen content of welding steel wire rod

A technology for welding steel and nitrogen content, which is applied in the field of smelting production technology, can solve problems such as fracture, high cost, and large drawing volume, and achieve the effects of simple process lines, reduced processing costs, and low production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

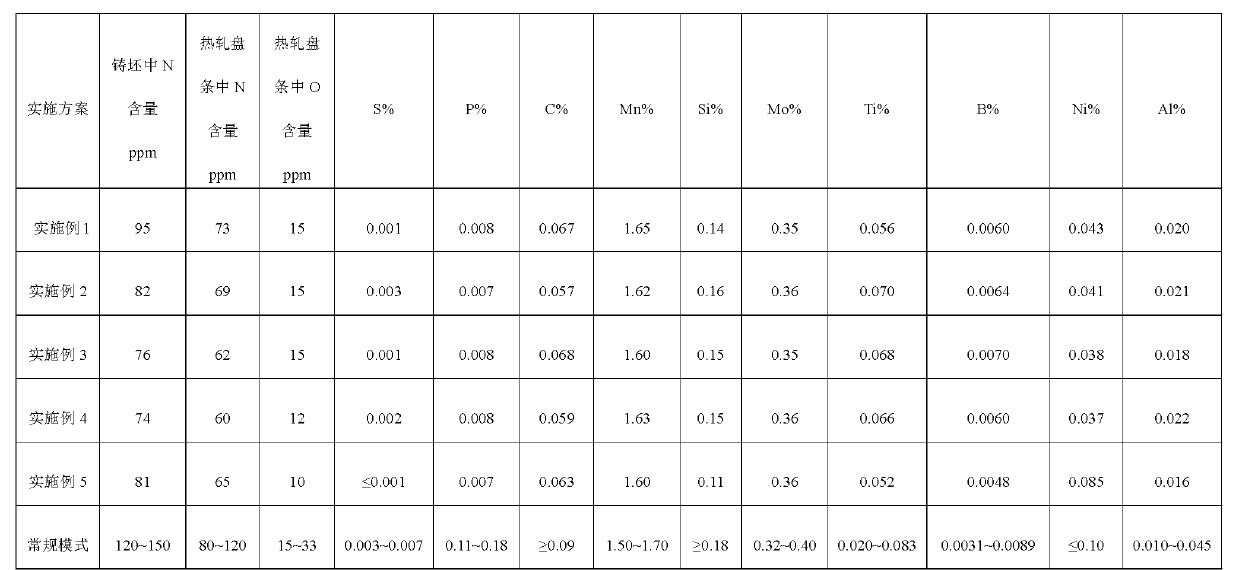

Examples

Embodiment 1

[0028] 1) High-quality welding steel wire rods are smelted and produced by low-level electrocardiographic furnace → LF refining furnace → continuous casting process.

[0029] 2) The charging capacity of primary smelting furnace is 72 tons, using the combination of molten iron + scrap steel, of which the amount of molten iron is 64t; the composition and temperature control requirements of the end point of electric furnace tapping: C: 0.04%, P: 0.06%, N: 60ppm, tapping Temperature: T=1620°C; 60kg of aluminum ingots and 800kg of active lime are added during tapping, and slag is strictly prohibited during tapping.

[0030] 3) Add 1000kg manganese metal and 450kg ferromolybdenum before the molten steel enters the refining furnace after tapping.

[0031] 4) In order to reduce the amount of nitrogen absorbed by molten steel, after entering the refining furnace, first add 500kg of active lime, then add 200kg of fluorite, and finally add 90kg of Al pellets; heat at 1540°C for 7 minutes...

Embodiment 2

[0038] 1) High-quality welding steel wire rods are smelted and produced by low-level electrocardiographic furnace → LF refining furnace → continuous casting process.

[0039] 2) The charging capacity of the primary furnace is 75 tons, using the combination of molten iron + scrap steel, of which the amount of molten iron is 63t; the composition and temperature control requirements of the end point of electric furnace tapping: C: 0.04%, P: 0.05%, N: 58ppm, tapping Temperature: T=1634°C; 65kg of aluminum ingots and 800kg of active lime are added during tapping, and slag is strictly prohibited during tapping.

[0040] 3) Add 1000kg manganese metal and 450kg ferromolybdenum before the molten steel enters the refining furnace after tapping;

[0041] 4) In order to reduce the amount of nitrogen absorbed by molten steel, after entering the refining furnace, first add 500kg of active lime, then add 200kg of fluorite, and finally add 90kg of Al pellets; heat at 1540°C for 7 minutes; the...

Embodiment 3

[0048] 1) High-quality welding steel wire rods are smelted and produced by low-level electrocardiographic furnace → LF refining furnace → continuous casting process.

[0049] 2) The charging capacity of the primary furnace is 76 tons, and the combination of molten iron and scrap steel is adopted, of which the amount of molten iron is 62t; the composition and temperature control requirements of the end point of electric furnace tapping: C: 0.03%, P: 0.06%, N: 54ppm, tapping Temperature: T=1641°C; 68kg of aluminum ingots and 600kg of active lime are added during tapping, and slag is strictly prohibited during tapping.

[0050] 3) Add 1000kg manganese metal and 450kg ferromolybdenum before the molten steel enters the refining furnace after tapping;

[0051] 4) In order to reduce the amount of nitrogen absorbed by molten steel, after entering the refining furnace, first add 500kg of active lime, then add 150kg of fluorite, and finally add 110kg of Al pellets; heat at 1540°C for 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com