Preparation method of photocatalyst taking silicon carbide as carrier

A photocatalyst, silicon carbide technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., to achieve good thermal conductivity, good thermal conductivity, good mechanical strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

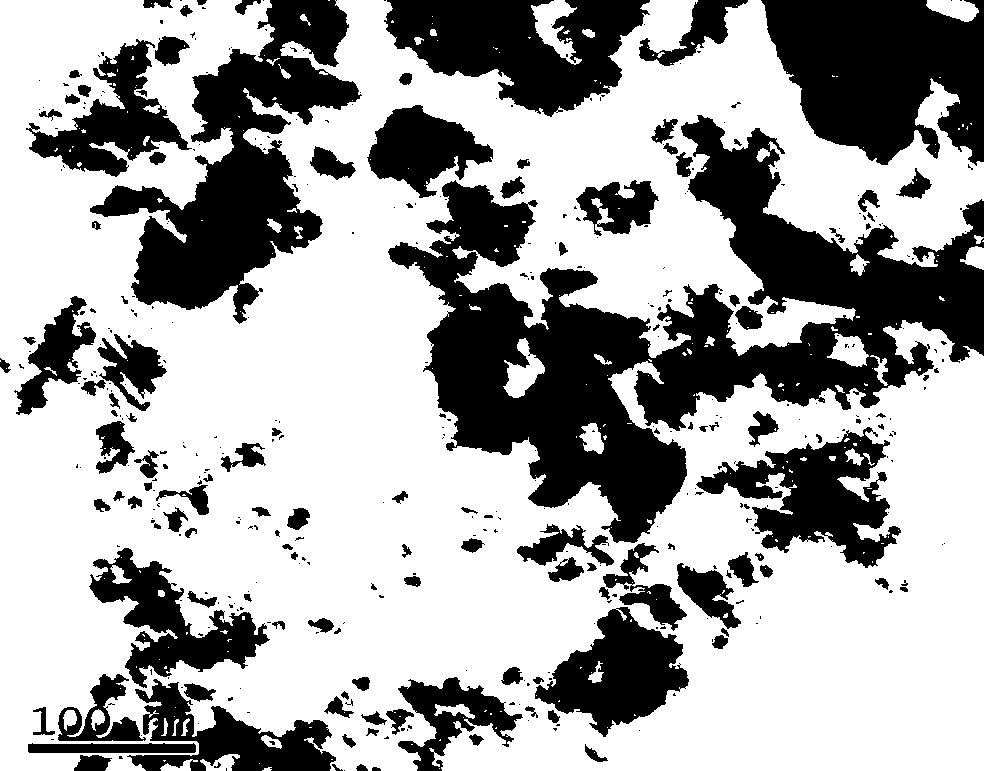

Image

Examples

Embodiment 1

[0019] Take 9% cadmium sulfide as an example to illustrate how to obtain thiourea and chromium chloride. The calculation principle of other embodiments is the same as that of embodiment 1.

[0020] A method for preparing a photocatalyst with silicon carbide as a carrier, the preparation steps include:

[0021] (1) Weigh 40mg (0.001mol) of silicon carbide, add thiourea solution (the mass of thiourea is 2.09mg, 0.0000275mol), stir evenly, and then drip into the chromium chloride solution (the mass of chromium chloride is 4.06 mg, 0.0000275mol), to obtain the mixed solution, then adjust the pH of the mixed solution to 8 by 1mol / L NaOH solution, and reflux at 100°C for 9h; the stirring step: use a magnetic stirrer to stir at 300r / min for 0.8h;

[0022] (2) The refluxed samples were washed with distilled water and ethanol, dried at 60°C for 5 hours, and then dried at 120°C to a constant weight to obtain a photocatalyst supported by silicon carbide. The photocatalyst was sulfided The con...

Embodiment 2

[0024] A method for preparing a photocatalyst with silicon carbide as a carrier, the preparation steps include:

[0025] (1) Weigh silicon carbide, add thiourea solution, stir well, then drop chromium chloride solution to obtain a mixed solution, then adjust the pH of the mixed solution to 9 with 1mol / L NaOH solution, and reflux at 100°C for 12h; Said stirring step: stirring with a magnetic stirrer at 800r / min for 0.5h;

[0026] (2) The refluxed samples were washed with distilled water and ethanol respectively, dried at 60°C for 4h, and then dried at 120°C to constant weight to obtain a photocatalyst with silicon carbide as the carrier. The photocatalyst was sulfided The content of cadmium is 15% of the total weight of the photocatalyst.

Embodiment 3

[0028] A method for preparing a photocatalyst with silicon carbide as a carrier, the preparation steps include:

[0029] (1) Weigh out silicon carbide, add thiourea solution, stir evenly, then drop chromium chloride solution to obtain a mixed solution, then adjust the pH of the mixed solution to 10 with 1mol / L NaOH solution, and reflux at 100°C for 10h; Said stirring step: using a magnetic stirrer to stir at 600r / min for 0.7h;

[0030] (2) The refluxed samples were washed with distilled water and ethanol, dried at 60°C for 3 hours, and then dried at 120°C to constant weight, to obtain a photocatalyst with silicon carbide as the carrier. The photocatalyst was sulfided The content of cadmium is 25% of the total weight of the photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com