Preparation method of isotropic pyrolytic carbon

An isotropic, pyrolytic carbon technology, applied in the preparation/purification of carbon, etc., can solve the problems of limiting the density of isotropic carbon blocks, unfavorable application of isotropic carbon, etc., achieving small crystallite size and reducing preparation effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

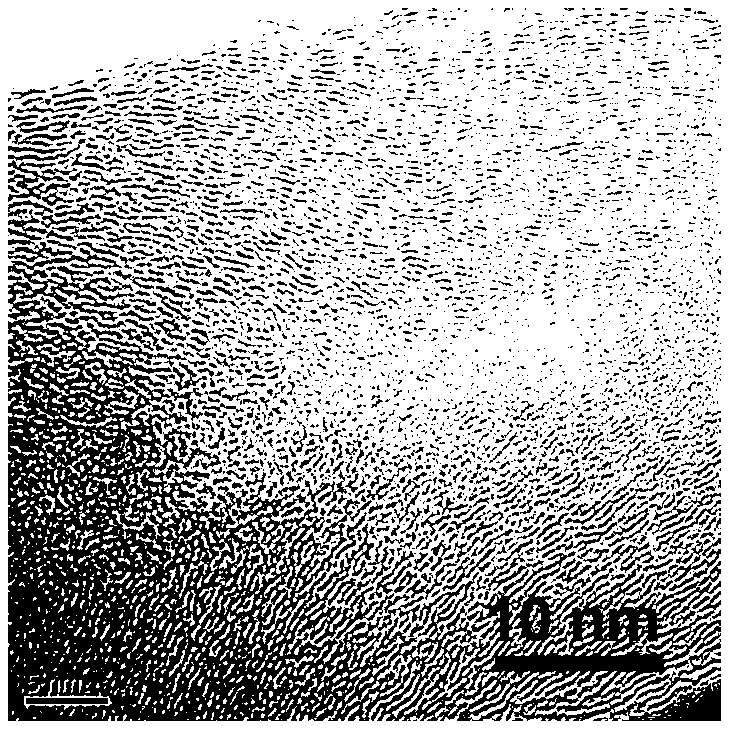

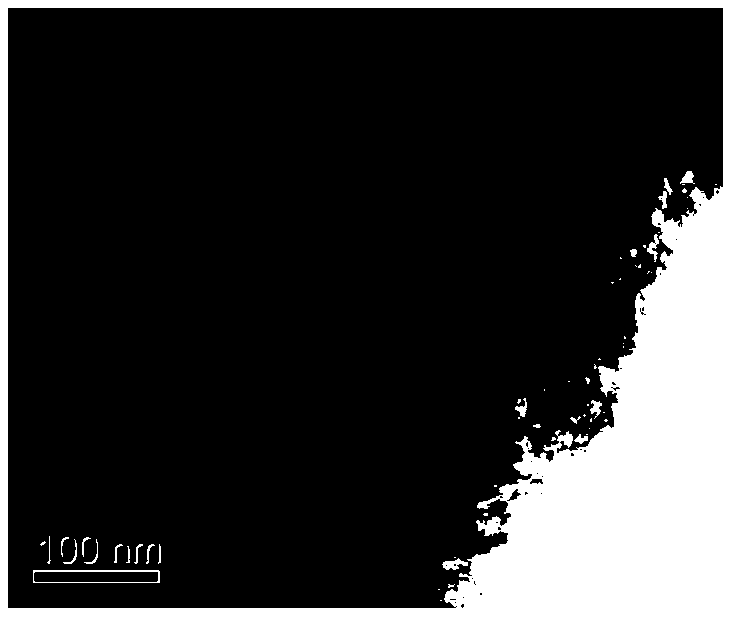

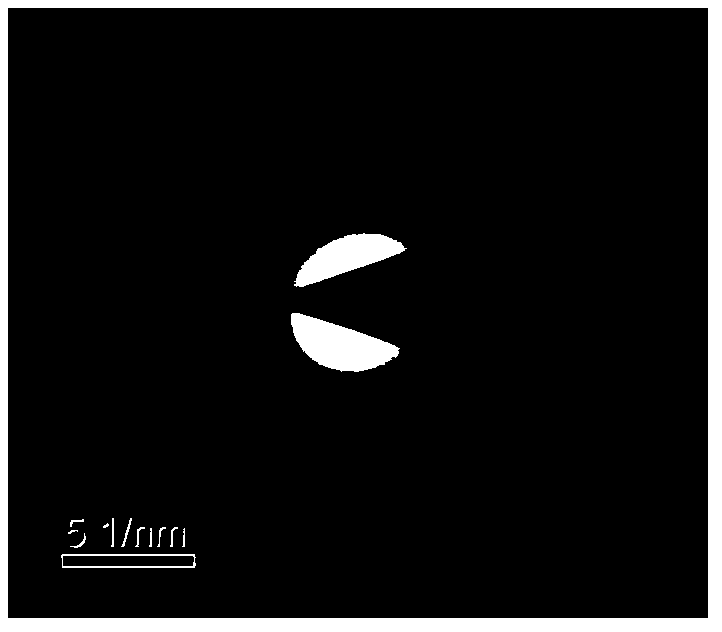

Image

Examples

example 1

[0025] (1) Using amorphous carbon nanofibers as raw materials, wet the carbon nanofibers with alcohol. When wetting, the volume ratio of alcohol and amorphous carbon nanotube fibers is 1:1.

[0026] (2) Press the wetted carbon nanofibers into a rectangular graphite die (groove size is 40×5×2), the pressure is 15MPa, and the holding time is 5min. After that, it was placed in a backlit environment at room temperature to dry to obtain a carbon nanofiber preform with a volume fraction of 30%.

[0027] (3) Put the graphite die containing amorphous carbon nanofibers into a fixed-bed CVD reactor, and raise the temperature to 950°C under the protection of nitrogen (nitrogen flow: 100L / h).

[0028] (4) After the temperature rises to the set value, turn off the nitrogen, and at the same time feed the mixed gas of propylene / hydrogen. The flow rates of propylene and hydrogen are 30L / h and 150L / h respectively. The reaction time is 3 hours, the power is turned off to cool down, the coolin...

example 2

[0031] (1) Using amorphous carbon nanofibers as raw materials, wet the carbon nanofibers with alcohol. When wetting, the volume ratio of alcohol and amorphous carbon nanotube fibers is 1:1.

[0032] (2) Press the wetted carbon nanofibers into a rectangular graphite die (groove size is 40×5×2), the pressure is 20MPa, and the holding time is 5min. After that, it was placed in a backlit environment at room temperature to dry to obtain a carbon nanofiber preform with a volume fraction of 40%.

[0033] (3) Put the graphite concave mold containing amorphous carbon nanofibers into a fixed bed CVD reaction furnace, and raise the temperature to 930°C under the protection of nitrogen (nitrogen flow rate: 100L / h).

[0034] (4) After the temperature rises to the set value, turn off the nitrogen, and at the same time pass in the mixed gas of propylene / hydrogen, the flow rates of propylene and hydrogen are 40L / h and 140L / h respectively. The reaction time is 3 hours, the power is turned of...

example 3

[0037] (1) Using amorphous carbon nanofibers as raw materials, wet the carbon nanofibers with alcohol. When wetting, the volume ratio of alcohol and amorphous carbon nanotube fibers is 2:1.

[0038] (2) Press the wetted carbon nanofibers into a rectangular graphite die (groove size is 40×5×2), the pressure is 30MPa, and the holding time is 5min. After that, it was placed in a backlit environment at room temperature to dry to obtain a carbon nanofiber preform with a volume fraction of 45%.

[0039] (3) Put the graphite concave mold containing amorphous carbon nanofibers into the fixed bed CVD reaction furnace, and raise the temperature to 900°C under the protection of nitrogen (nitrogen flow: 100L / h).

[0040] (4) After the temperature rises to the set value, turn off the nitrogen, and at the same time feed the mixed gas of propylene / hydrogen. The flow rates of propylene and hydrogen are 50L / h and 130L / h respectively. The reaction time is 3 hours, the power is turned off to c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com