Method for extracting vanadium from production flow of aluminum oxide

A production process and alumina technology, applied in the field of vanadium extraction, can solve the problems of adverse production impact, long production process, low vanadium adsorption rate, etc., and achieve the effects of reducing vanadium extraction cost, reducing impact and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

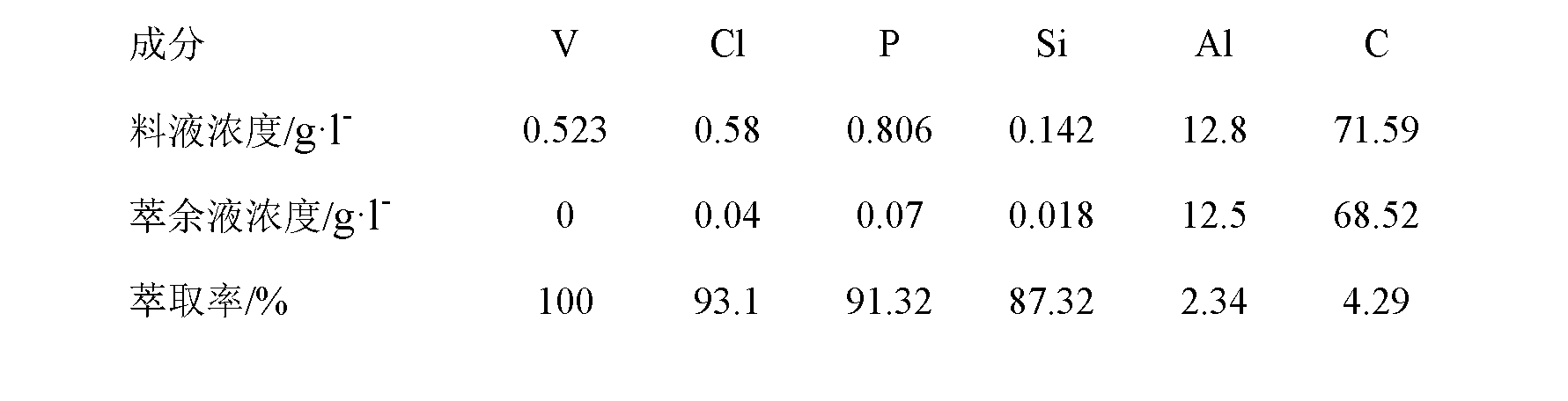

[0025] Take 1 liter of vanadium with a concentration of 0.523g.l -1 The carbon fraction mother liquor, wherein the total alkali concentration is 130 g l - , the concentrations of other impurities such as Cl, P, Si and Al are 0.58 g·l - , 0.806 g l - , 0.142 g l - , 12.8 g l - . At 20°C, add 15ml of 5% sodium oxalate solution to the mother liquor, stir and complex for 15 minutes; add 25%N263+10%TBP+65%sulfonated Extraction of kerosene composition The organic phase extracts the vanadium-containing complex in the mother liquor, the extraction time is 10 minutes, and the phase separation time is 3 minutes; the extraction results are shown in Table 1.

[0026] Table 1. Extraction results

[0027]

[0028] From the extraction results, the extraction rate of vanadium can reach 100%; most of the impurities such as Cl, P, and Si in the mother liquor can also be extracted, while the extraction rates of Al and C are very low.

[0029] The above-mentioned loaded organic phase wa...

Embodiment 2

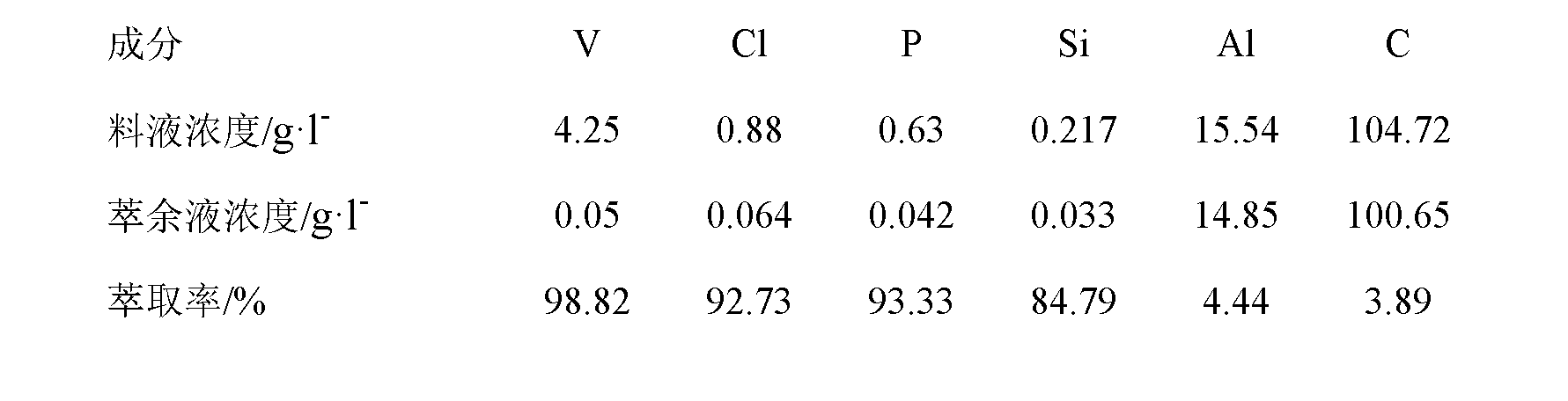

[0038] Take 1 liter of vanadium-containing carbon fraction mother liquor, wherein the total alkali concentration is 180 g l - , with a vanadium concentration of 3.55 g.l - , the concentrations of other impurities such as Cl, P, Si and Al are 0.92 g·l - , 0.68 g l - , 0.235 g l - , 13.41 g l - . At 50°C, add 15ml of 5% sodium potassium tartrate solution to the mother liquor, stir and complex for 30min; add 25%N263+10%TBP+65%sulfur Extraction of kerosene composition The organic phase extracts the vanadium-containing complex in the mother liquor, the extraction time is 25 minutes, the temperature is maintained at 50°C during the extraction period, and the phase separation time is 5 minutes; the extraction results are shown in Table 4.

[0039] Table 4. Results of extraction experiments

[0040]

[0041] Wash the above-mentioned loaded organic phase with distilled water, the washing ratio is O / A=1 / 1, the washing time is 25 min, and the phase separation time is 5 min; the ...

Embodiment 3

[0049] Take 1 liter of vanadium-containing carbon fraction mother liquor, wherein the concentration of total alkali is 220 g l - , the concentration of vanadium is 2.87 g.l - , the concentration of other impurities such as Cl, P, Si and Al is 0.75 g·l - , 0.45 g l - , 0.187 g l - , 16.25 g l - . At 80°C, add 15ml of 5% sodium citrate solution to the mother liquor, stir and complex for 10 minutes; add 55% TOMAC + 10% TBP + 35% according to the ratio of O / A=1 / 1 Extraction of sulfonated kerosene composition The organic phase extracts the vanadium-containing complex in the mother liquor. The extraction time is 20 minutes. During the extraction period, the temperature is maintained at 50 ° C and the phase separation time is 8 minutes. The extraction results are shown in Table 7.

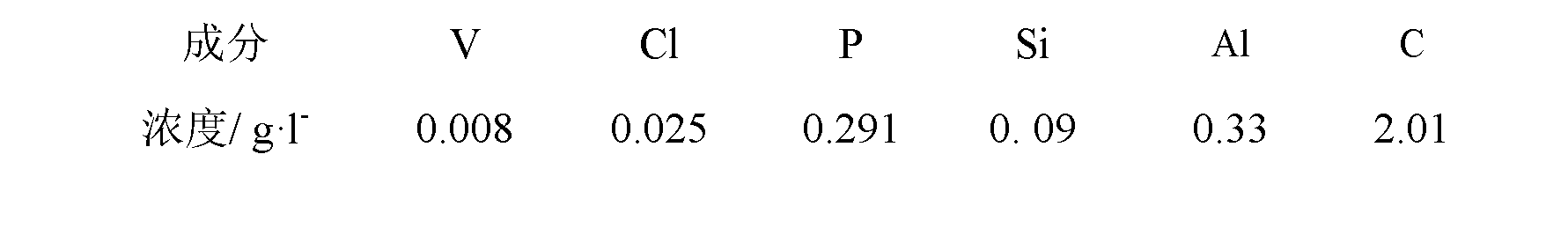

[0050] Table 7. Results of extraction experiments

[0051]

[0052] Wash the above loaded organic phase with distilled water, the washing ratio is O / A=1 / 3, the washing time is 20 min, and the pha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com