Method for lowering ash content of polyacrylonitrile-based carbon fiber

A polyacrylonitrile-based carbon fiber and carbon fiber technology, applied in the chemical characteristics of fibers, chemical post-processing of synthetic polymer rayon filaments, textile/flexible product manufacturing, etc., can solve the problem of not effectively reducing the ash content of carbon fibers, and achieve dense structure The effect of high chemical degree, low ash content and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

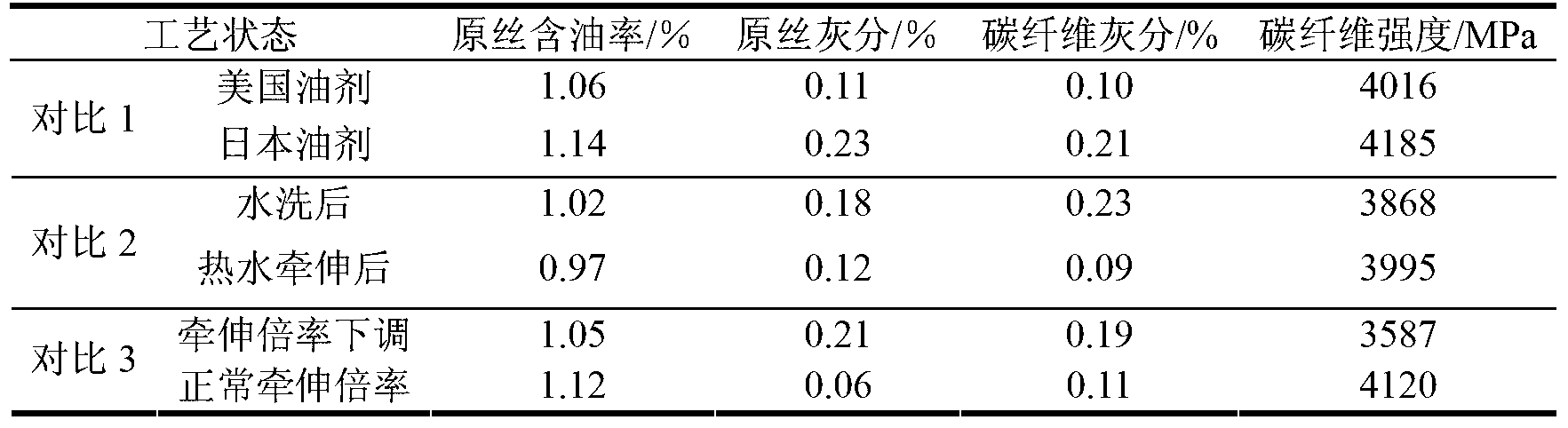

Examples

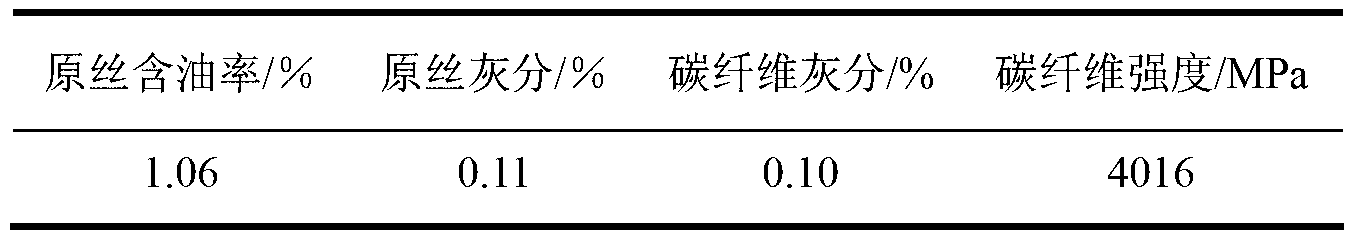

Embodiment 1

[0037] This embodiment is a method for reducing the ash content of polyacrylonitrile-based carbon fibers, and the specific process is:

[0038] The first step is the preparation of PAN-based protofilaments.

[0039] The preparation of the PAN-based protofilament provides the following steps:

[0040] Step 1, preparation of spinning solution. With acrylonitrile, methyl acrylate, itaconic acid, 2-acrylamide-2-methylpropanesulfonic acid and initiator azobisisobutyronitrile as the solute and dimethyl sulfoxide as the solvent, it is obtained by conventional preparation methods reaction solution. The weight ratio of described acrylonitrile, methyl acrylate, itaconic acid, 2-acrylamide-2-methylpropanesulfonic acid is 98.00:0.75:1.00:0.25; The concentration of azobisisobutyronitrile in solute is 0.9 wt%. The concentration of the solute in the reaction solution was 21.6 wt%.

[0041] The obtained reaction solution was polymerized by a conventional method in a polymerization tank, ...

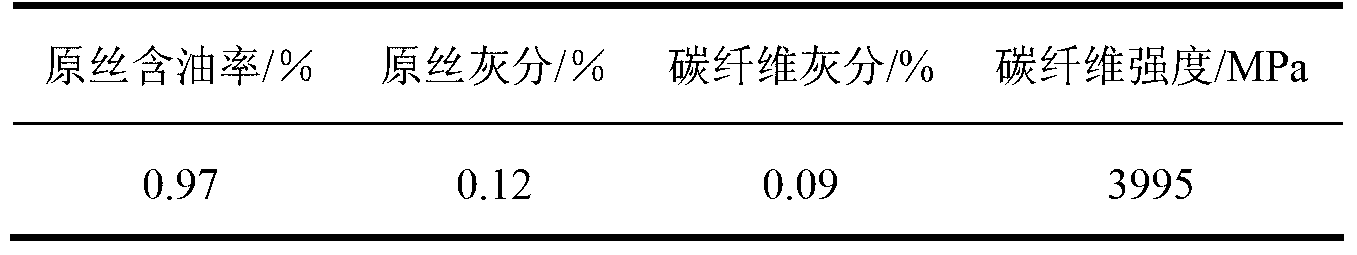

Embodiment 2

[0064] This embodiment is a method for effectively reducing the ash content of PAN-based precursors and carbon fibers.

[0065] The specific process includes two steps. The first step is the preparation of PAN-based raw silk: including the preparation and filtration of the spinning solution, the coagulation and molding of the spinning solution, the washing of the coagulated filaments, the hot water drawing of the washed silk, and the washing of the washed silk. The first oiling, the first drying and densification, the second oiling, the second drying and densification, the third oiling, and subsequent treatment; the second step is the preparation of PAN-based carbon fibers. The specific process of this embodiment is the same as that of Example 1, wherein the coagulation and shaping of the spinning solution, the water washing of the coagulated filaments, the hot water drafting of the water-washed silk, the first oiling of the water-washed silk, and the second coating The parame...

Embodiment 3

[0084] This embodiment is a method for effectively reducing the ash content of PAN-based precursors and carbon fibers.

[0085] The specific process includes two steps. The first step is the preparation of PAN-based raw silk: including the preparation and filtration of the spinning solution, the coagulation and molding of the spinning solution, the washing of the coagulated filaments, the hot water drawing of the washed silk, and the washing of the washed silk. The first oiling, the first drying and densification, the second oiling, the second drying and densification, the third oiling, and subsequent treatment; the second step is the preparation of PAN-based carbon fibers. The specific process of this embodiment is the same as that of Example 1, wherein the coagulation and shaping of the spinning solution, the water washing of the coagulated filaments, the hot water drafting of the water-washed silk, the first oiling of the water-washed silk, and the second coating The parame...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com