Artificial ligament and preparation method thereof

An artificial ligament and inner core technology, applied in ligaments, medical science, muscles, etc., can solve the problems of poor hydrophilicity and cell compatibility, lack of high polar groups, high crystallinity, etc., to increase biocompatibility , improve penetration, reduce inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The invention also discloses a method for preparing the artificial ligament, comprising the following steps:

[0035] (A) reacting the ligament of polyethylene terephthalate material with ozone to obtain polyethylene terephthalate with free radicals;

[0036] (B) Under the protection of an inert gas, the polyethylene terephthalate with free radicals in the solution containing monomer molecules is subjected to a closed polymerization reaction to obtain an artificial ligament;

[0037] The monomer molecules are sugar compounds or vinyl monomers containing hydrophilic groups.

[0038] In the present invention, the polyethylene terephthalate material ligament is used as a raw material, which is modified to obtain an artificial ligament with better biocompatibility. In the present invention, there is no special limitation on the source of the ligament of the polyethylene terephthalate material, which can be purchased from the market.

[0039] In the present invention, at f...

Embodiment 1

[0045] Add 20 grams of sodium styrene sulfonate to 100 ml of a mixed solution of water and ethanol, the volume ratio of water and ethanol is 1:9, heat at 70°C, filter the solution after the sodium styrene sulfonate dissolves, and place the filtrate at 4 degrees Refrigerate overnight, after the crystals are precipitated, filter and dry for later use.

[0046] Put the ligament of the PET material to be processed into 200ml of distilled water, open the oxygen bottle (0.6L / min), pass the ozone generator, and put the ozone (O 3 ) into distilled water and reacted for 10 minutes.

[0047] Make the recrystallized sodium styrene sulfonate crystals into a solution with a concentration of 15% by mass, pass in argon to drive out the oxygen in the solution, add ozonated PET material and directly seal the polymerization reaction at 70°C for one Hours, get the artificial ligament.

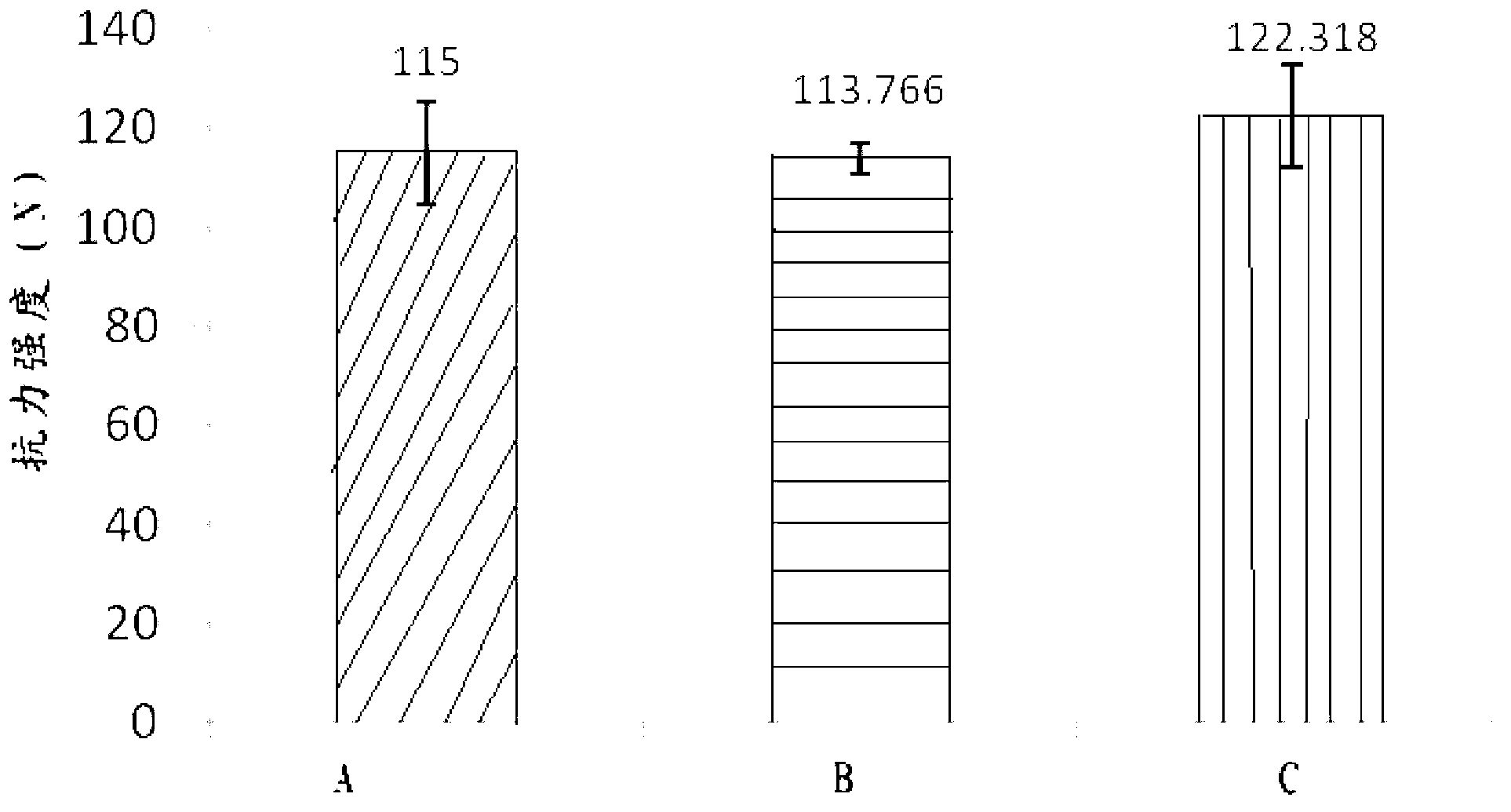

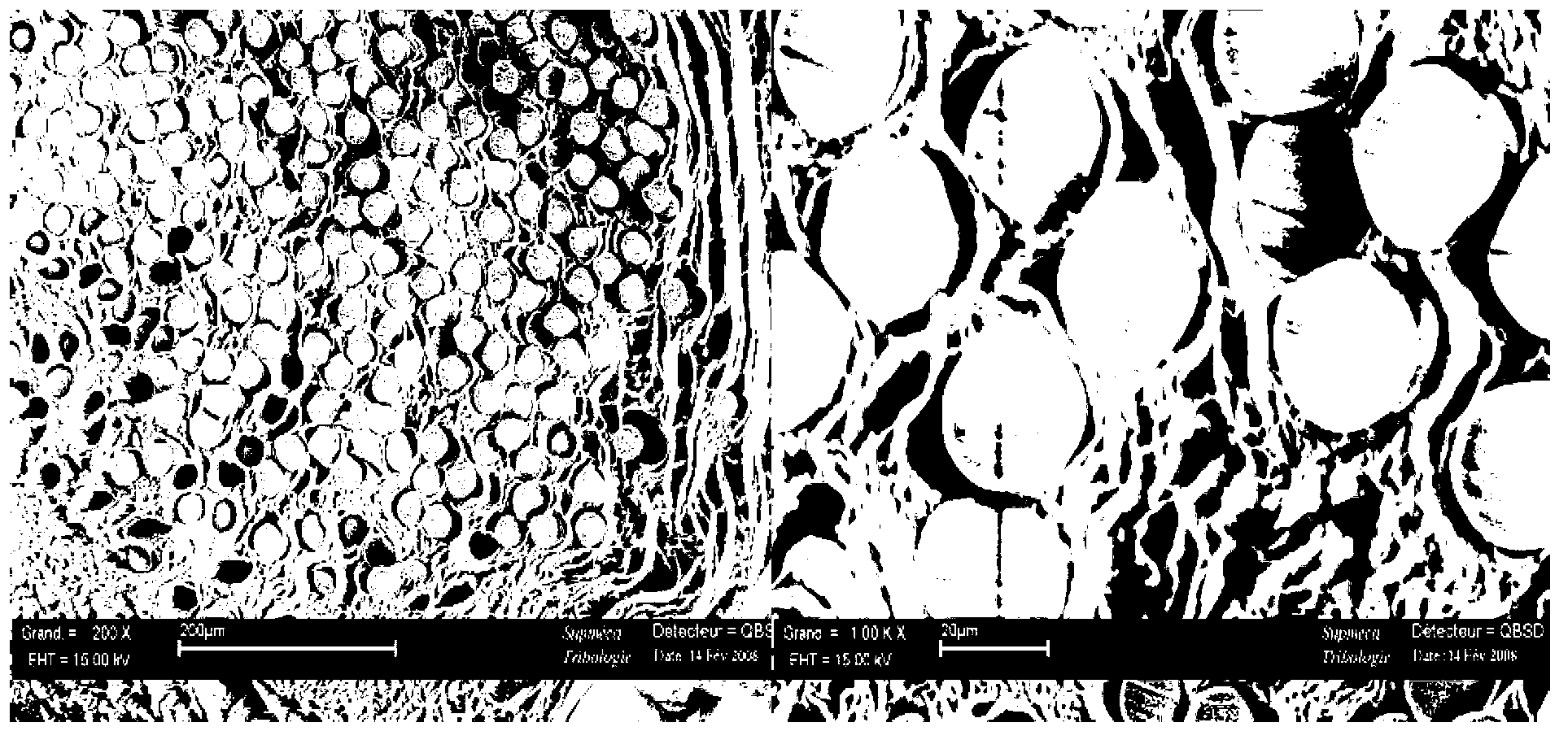

[0048] The obtained artificial ligament was determined by colorimetry. The artificial ligament was co-cultur...

Embodiment 2

[0054] Add 20 grams of sodium styrene sulfonate to 100 ml of a mixed solution of water and ethanol, the volume ratio of water and ethanol is 1:9, heat at 70°C, filter the solution after the sodium styrene sulfonate dissolves, and place the filtrate at 4 degrees Refrigerate overnight, after the crystals are precipitated, filter and dry for later use.

[0055] Put the artificial ligament of PET material that needs to be processed into 200ml of distilled water, open the oxygen bottle (0.6L / min), and pass the ozone generator (O 3 ) into distilled water and reacted for 10 minutes.

[0056] The recrystallized sodium styrene sulfonate crystals were made into a solution with a concentration of 15% by mass, and argon gas was introduced to drive out the oxygen in the solution, and the ozonated PET material was added to directly seal the polymerization reaction at 70°C for 3 times Hours, get the artificial ligament.

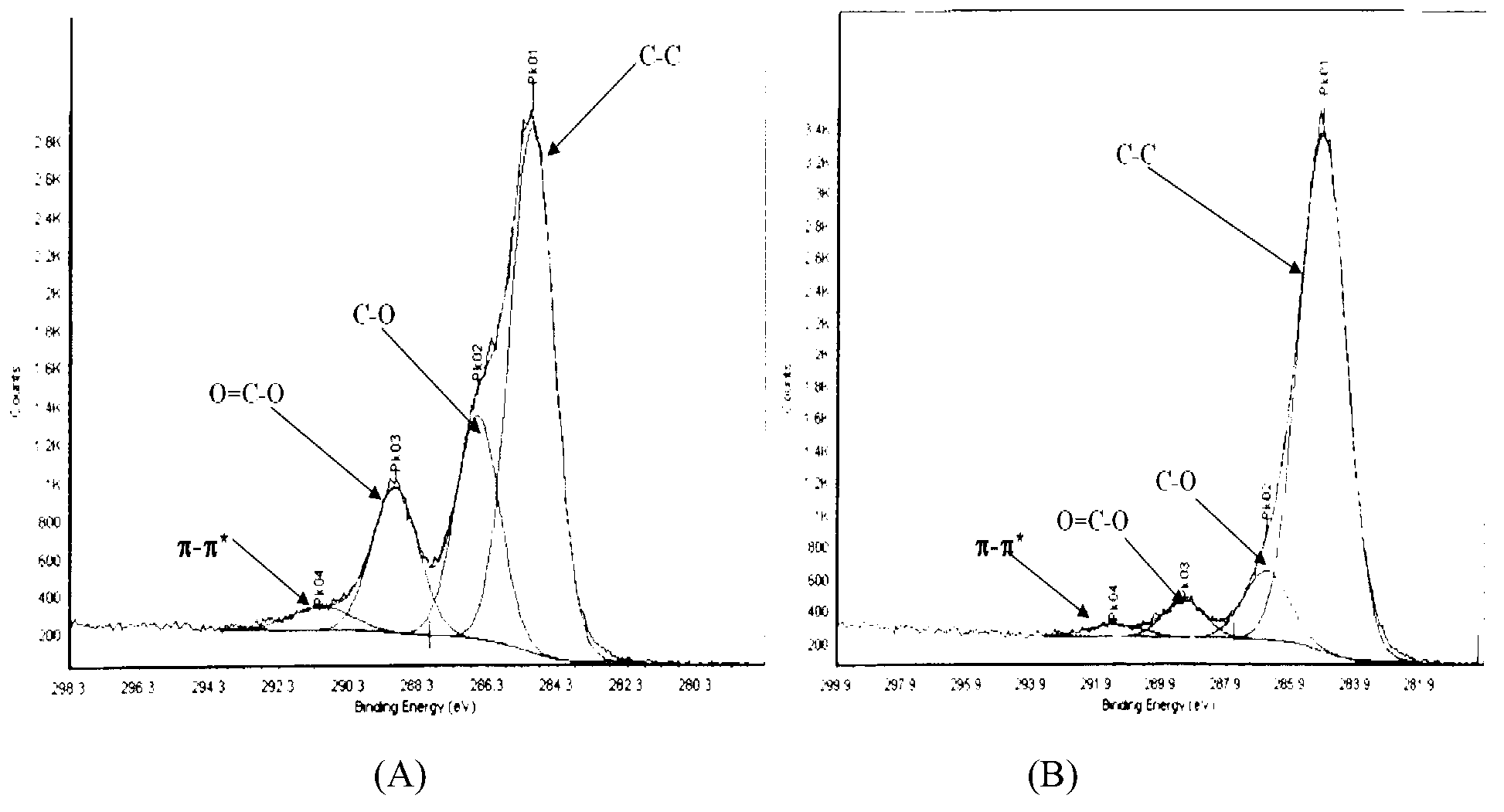

[0057] X-ray photoelectron spectroscopy (XPS) was performed on the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com