Method for preparing palladium carbon by using organic carbon monoxide releasing molecule (CORM) and catalytic application of method

A carbon monoxide and palladium carbon technology, applied in the field of catalyst preparation, can solve the problems of low recycling rate, high catalytic activity, high loading rate, etc., and achieve the effects of reducing production cost, wide source of raw materials, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] 1. Pretreatment of activated carbon

[0017] Take 1.0g of granular coconut shell activated carbon (coconut shell AC), wash it with tap water for 7 to 8 times to remove soluble impurities and small solid particles, and then wash it with 0.1mol / L hydrochloric acid aqueous solution for 2 to 3 times to remove oxides in the activated carbon and hydroxide, then washed with distilled water until neutral, and dried in an oven at 120°C for 24 hours to remove the moisture in the pores of activated carbon.

[0018] 2. Preparation of Palladium Carbon

[0019] According to the Pd load of 10wt.%, add 1g of pretreated coconut shell activated carbon to 7.5mL of N,N-dimethylformamide, add 0.1667g of palladium chloride, stir at 200 rpm, and heat to 70°C , constant temperature immersion reduction reaction for 8 hours, filtered, washed 2 to 3 times with distilled water, dried at 60°C for 24 hours, and prepared into palladium carbon.

Embodiment 2

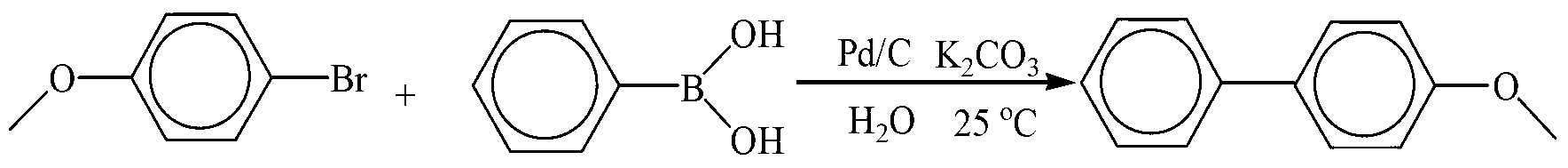

[0021] The palladium carbon prepared by embodiment 1 is used in catalyzing the reaction of p-bromomethoxybenzene and phenylboronic acid, and its specific use method is as follows:

[0022] Add 63.5uL (0.5mmol) p-bromomethoxybenzene, 67.1mg (0.55mmol) phenylboronic acid, 82.1mg palladium carbon, 4mL distilled water, 20.7mg potassium carbonate to a 25mL round bottom flask, stir at room temperature for 4 hours, chemical reaction The equation is as follows:

[0023]

[0024] After the reaction is finished, filter, and the filtrate is concentrated and separated by silica gel column chromatography to obtain p-methoxybiphenyl, weighed, and the yield is calculated. The palladium carbon catalyst is washed 3 to 5 times with distilled water to remove possible residual inorganic soluble impurities, and then Wash with ethanol and ethyl acetate 3 to 5 times to remove possible residual organic impurities, dry in vacuum at 60°C for 12 hours, and recover.

[0025] The recovered palladium-c...

Embodiment 3~5

[0030] In the pretreatment step 1 of embodiment 1 activated carbon, the granular coconut shell AC used is replaced with granular coal AC, granular fruit shell AC or granular wood AC of equal quality, and other steps are the same as in Example 1, and are prepared into palladium carbon.

[0031] The prepared palladium carbon was used to catalyze the reaction of p-bromomethoxybenzene and phenylboronic acid according to the method of Example 2, and the test results are shown in Table 2.

[0032] The catalytic activity of the palladium carbon prepared by table 2 embodiment 3~5

[0033]

[0034] It can be seen from Table 2 that the palladium carbon prepared by using activated carbon with different shapes as the carrier has good catalytic activity for the reaction of p-bromomethoxybenzene and phenylboronic acid, and the conversion rate of p-bromomethoxybenzene can reach 92%. Above, the catalyst recovery rate can reach more than 99%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com